A look at the food industry's key challenges and if (and how) RFID can solve them.

Is RFID finally ready to take on the food industry?

Radio frequency identification (RFID) has become established as a dominant force in the apparel industry, with the technology finally approaching mass adoption after years of threatening to.

The technology involves tags or “labels” that emit a small radio frequency, allowing radio stock counts that are both highly accurate and incredibly fast compared to traditional methods. The result of this is a very up to date, or even real-time, view of stock. The main use cases responsible for the technology’s success include the increased process efficiency, superior inventory management and the enablement of seamless omnichannel services.

That’s the story of RFID in apparel, but what about other retail industries? After years of technical roadblocks that have kept the technology out of other markets, the technology has matured to a point where new industries are RFID-viable for the first time ever. The beauty and cosmetics industry is beginning to take notice of RFID, and perhaps now food retailers should do the same.

Why? Because modern RFID is so well positioned to tackle the food industry’s unique challenges, like optimising inventory, minimising food waste and increasing the traceability of the supply chain.

Whilst this sounds great, the limitations of the technology that we mentioned earlier have historically meant RFID just wasn’t viable for the food market. As well as liquid and metallic products traditionally interfering with the RFID signals, the food industry’s drastically lower average article price compared to the apparel industry were significant roadblocks. But this changing…

Mature RFID technology is ready to take on the food industry

RFID is reaching a level of maturity that means the previous barriers to entry for the food industry are starting to disappear:

- The price of individual RFID tags has fallen significantly, making it viable for more and more food products.

- RFID tags have become smaller – so it’s now possible to label even the smallest items.

- More advanced tags now exist that work on metal and liquid products

- Durable tags that survive high and low temperatures and even microwaves are now available, meaning all kinds of food packaging can be tagged with RFID.

Because of these changes we are already seeing the first steps of RFID breaking into the food industry, with RFID-giant Avery Dennison beginning to operate in the market and last year the first-ever blockchain beef shipment taking place using RFID tagging, providing a potentially industry-changing level of traceability and assurance only possible through RFID.

Superior inventory management for efficient operations.

The first major use case for RFID in the food industry is one already tried and tested in apparel – superior inventory management. Replacing manual stock-keeping methods with fast and highly accurate RFID processes gives retailers a reliable and up-to-date view of their entire stock. Whilst having a clear view of store inventory is highly beneficial for any retail business but for the food industry, where items have to be managed and monitored much more intensely, an RFID system could cut shelf life labour costs by up to 50%. Another major impact of the 99% stock accuracy RFID provides is the reduction in inventory sizes due to not needing extra ‘safety stock’, this could have a major economic effect for food retailers and would also stop inventory shrinkage from expiry dates. Leading us to our next major use for RFID in food retail:

Reducing Food Waste

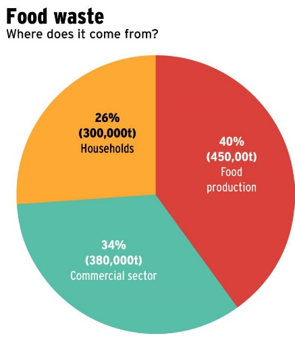

Food waste is a massive problem. Every year in the UK alone 18 million tonnes of food end up in landfill, Around 1/3 from producers/ supply chain, 1/3 from retail and 1/3 from households. Not only is this an environmental and ethical issue, but for the food industry itself, this sees huge amounts of capital literally wasting away.

When it comes to retail, fresh produce and waste due to shelf-life is a unique issue to the food industry, but one RFID (and an effective RFID platform) is well suited to manage. Expiry dates result in a huge amount of food waste in the commercial sector and are also very labour intensive to manage on the shop floor.

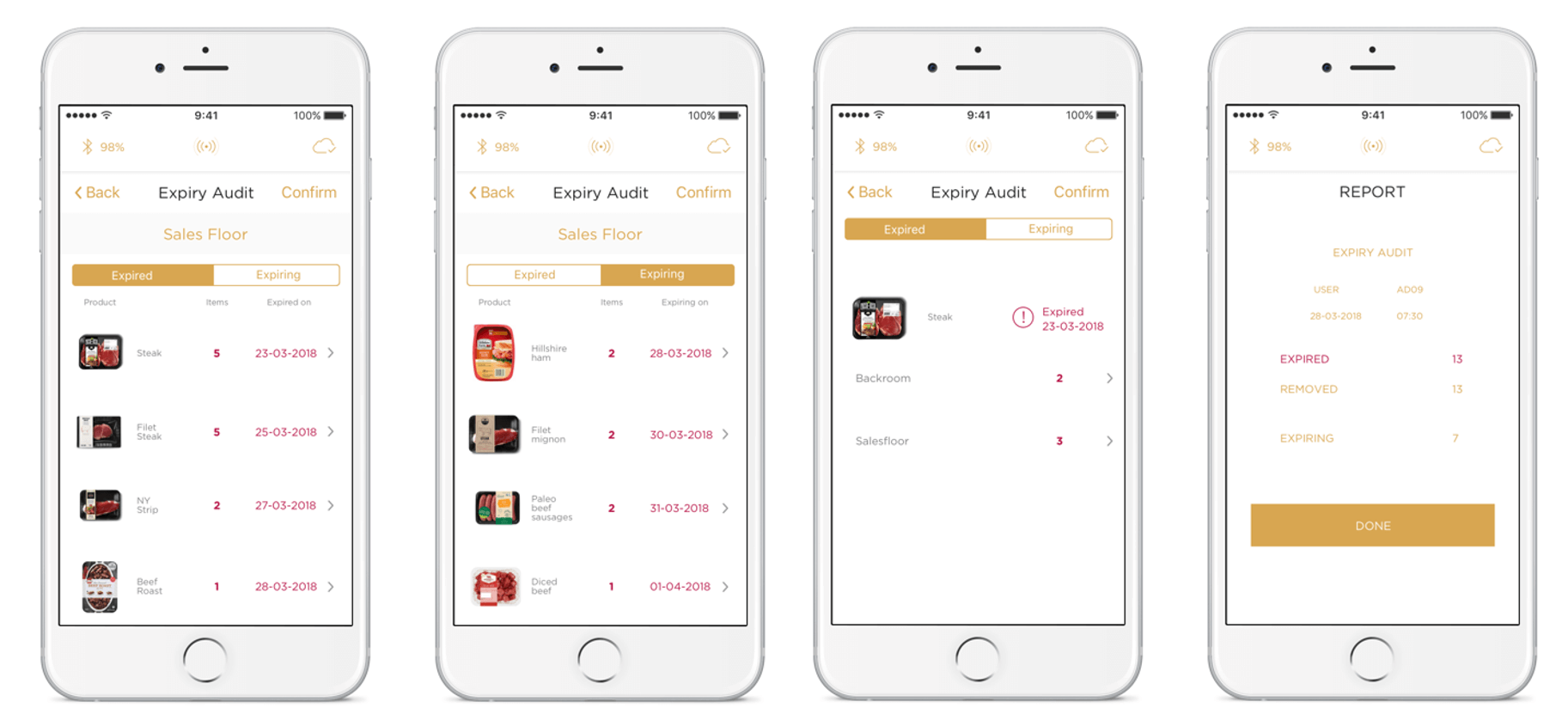

So how might RFID solve this problem? The benefits that the accurate and item-level view of stock RFID provides has been well documented in the apparel sector, but with the food industry, this real-time view of stock will be even more valuable. An Internet of Things platform (giving individual physical objects a unique digital identity) designed specifically for use with food products would not only be able to monitor and maintain stock levels on shelves but could monitor the expiry date of individual products, alerting staff when items are nearing expiry or need to be marked down.

A fully Visible and Transparent Supply Chain – for consumer satisfaction and better handling of product recalls.

The final major use case of RFID for the food industry is the traceability of products through the supply chain. Whilst other retail industries get value out of this in terms of warehouse efficiency and smooth operations between distribution centres and stores, the food industry is an industry where traceability of products is a major concern, for consumers just as much as retailers. People are increasingly concerned with where their food comes from, and suppliers and retailers could look to take advantage of RFID traceability and even utilise new blockchain methods alongside this to offer their customers assurances and gain the trust of consumers. We are already in the very early stages of this having already seen the first blockchain beef shipment take place, giving consumers 100% traceability and visibility of where their produce comes from.

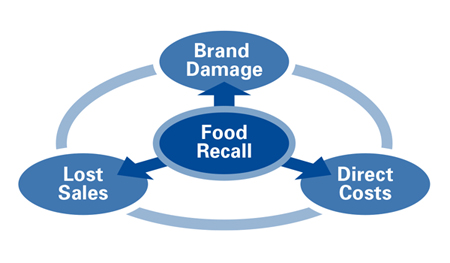

On the other end of the food traceability issue is food recalls. Product recalls are an unfortunately common problem in the food industry, costing the industry an estimated $55.5 billion a year. A recent example of this being the major recall of humous products across the UK due to salmonella. These have a huge impact on the industry, not only economically but also on brand reputation. RFID’s ability to accurately trace individual items across an entire supply chain could prove invaluable in such an event. Having complete accuracy would allow food suppliers to pinpoint exactly where the issue occurred and easily track where all other products from the compromised location were sent, allowing for fast and efficient recalls. This would also potentially reduce food wastage due to over-recall and increase consumer trust in the retailer.

Conclusion

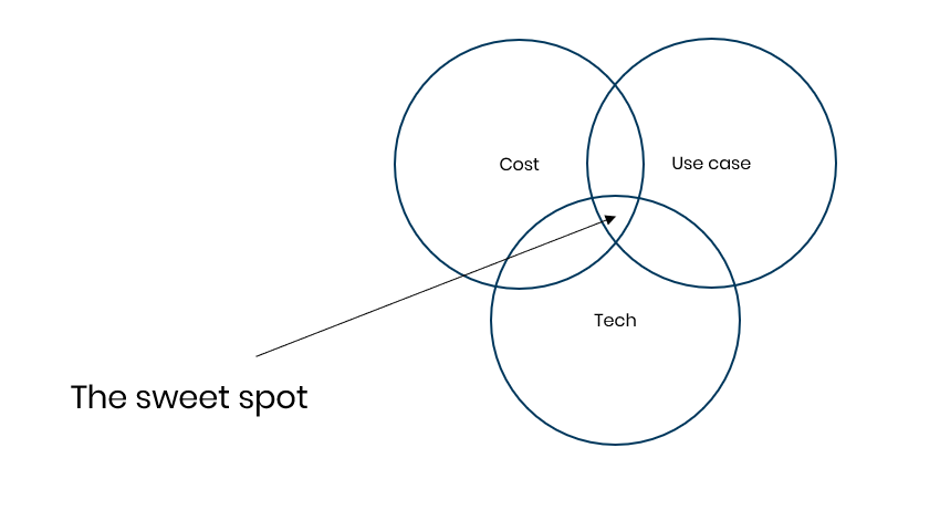

So, the food industry has several challenges that RFID has been proven to solve and the technology has gotten to a point where it is viable among the much more diverse and complicated range of products. The only thing that may hold it back is the cost. Whilst the price of tags has dropped significantly, the price point for food products is far lower than in apparel. This may prove a barrier for tagging some food items, at least initially. Fresh products like meat and fish (and potentially some fruit and veg) however have both a high enough price point and a limited shelf life meaning managing them with RFID could prove hugely beneficial. The food industry is a new frontier for RFID, and time will tell just how well it does in the market. But make no mistake, in the coming years we will see it attempted, and the success of the technology in the industry will be decided, one way or another.