Warehouse

Full transparency along the entire supply chain

Automated and efficient RFID software for warehouses and distribution centres

RFID software for the warehouse

The digital supply chain

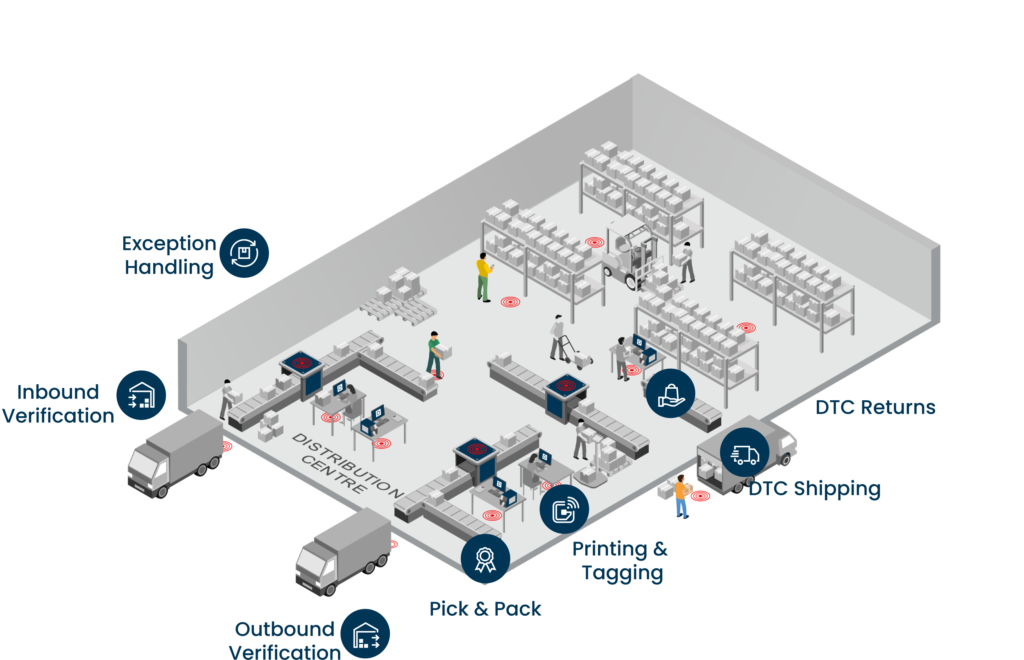

Detego’s RFID-based warehouse software enables retailers to automate and dramatically improve their receiving, picking/packing and shipping processes in factories and/or distribution centers. These steps are vital parts of an end-to-end RFID solution, providing full visibility across the entire supply chain.

Future-proof your supply chain with real-time data

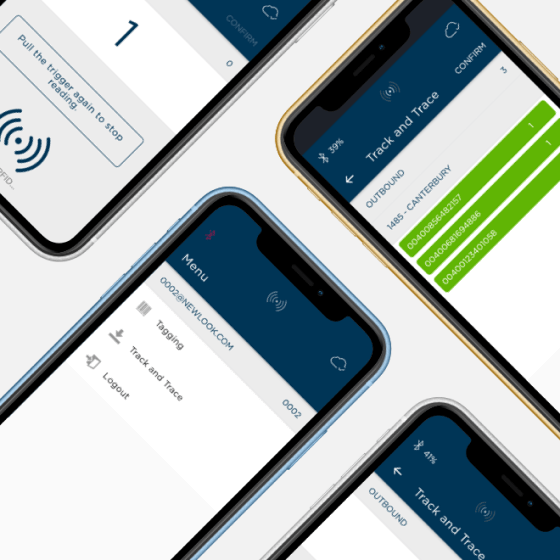

Detego’s RFID-based software has all the features you need to establish efficient goods out and goods in processes, keep track of returns, reduce mispicks and other warehouse errors. Additionally, Detego integrates with all forms of RFID hardware (tunnels, readers, handhelds, printers) and existing Warehouse Management Systems to make for a quick and easy implementation.

Explore our features

Detego Warehouse for shorter time to market

Detego Warehouse, a part of the Detego Platform, takes care of item visibility in the warehouse and ensures a massive increase in transport speeds in logistics. The software “follows” merchandise on an item level. In this way, the receipt of entire shipments of merchandise takes place completely automatically and at the single item level. In terms of distribution, the status of all pieces always remains transparent; cost-intensive delivery errors can thus be eliminated.

The RFID warehouse software is capable of moving millions of pieces of clothing more quickly and without errors. In this way logistics service providers can better handle the delivery pressure of many collections from the manufacturer over the year and at the same time better match the tempo of their retail customers.

For retailers that provide end-customers with shipments via their webshops, Detego InWarehouse offers exactly the accuracy in webshop availability information that is expected by customers thanks to the real-time article transparency at the individual item level it provides. Historical data offers no real picture of the actual inventory.

Customer satisfaction starts with the warehouse.

Detego InWarehouse from the perspective of …

Logistics providers profit from Detego InWarehouse.

FAQ's

Warehouse Management System (WMS) and Warehouse Control System (WCS). These systems send and receive product master data to and from the Detego software in the warehouse. They also send and receive target lists for shipments (cases, ASNs, cartons). The data contains information mainly about boxes and their content. This information is time-critical as it influences box routes in an automated conveyor system and allows exception handling to occur in a timely fashion.

As every warehouse/DC is different, we do not provide ‘fixed’ packages. However, we have developed a best practise approach and can recommend the key software modules and hardware to implement inline with your business needs.

Detego integrates with all forms of hardware in the warehouse to enable efficient and automated processes. These include handheld readers, fixed readers (High-density RFID chambers, Overhead RFID readers, RFID tables, RFID tunnels) and RFID printers.