This article explores planograms, their challenges they present and how retails ongoing digital revolution along with artificial intelligence is changing planograms as we know them.

AI revolutionises the Planogram

Planograms are a key part of running a retail store. In simple terms, they dictate the what, where and, the how many of products on the shop floor.

This article explores planograms, the challenges they present and how retails ongoing digital revolution along with artificial intelligence is changing planograms as we know them.

What is a planogram?

A planogram defines the location and quantity of products to be placed on display. They essentially function as blueprints for all merchandise within a store.

Alongside the visual merchandising element, planograms aim to optimise article availability and thus specifically stimulate sales.

So, a store planogram has two aspects:

1 – The Merchandising: which articles are presented on the sales floor and how (visual merchandising)

2 – The detailed quantities for individual colour and sizes (availability optimisation)

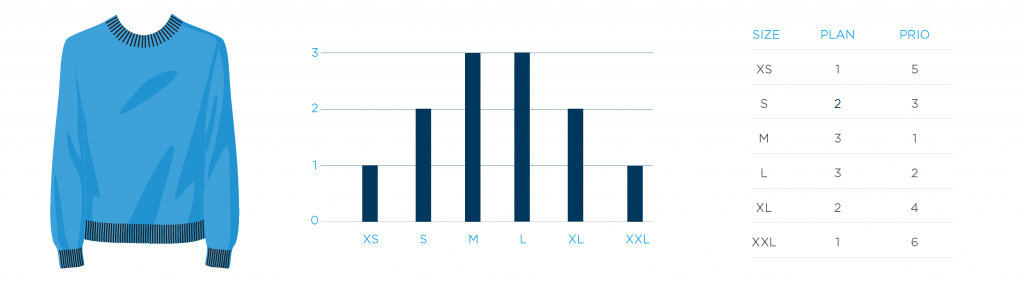

For example, a planogram might state where a formal shirt is displayed on the shop floor. The planogram will also state what quantities should be displayed, specific to different sizes and colours. So the planogram may state 3 mediums, 2 smalls, 2 larges and 1 extra-large are available on the shop floor, and so on.

Ideally, merchandising and planograms go hand in hand: customers are inspired by the presentation and then, their desired product is available in the matching size. The reality, however, often paints a different picture.

Planogram – Merchandising

Planogram – Quantities and Priorities

Visually appealing and available in relevant sizes

What are the challenges of setting and maintaining a retail planogram?

Breaking this down, there are two questions that retailers face:

1) How do you define a planogram for my stores with a suitable size distribution?

The first question can be a challenge for retail depending on your definition of suitable. The reality is simply that manually creating and defining different size distributions for every single product is incredibly time-consuming and rarely worth the effort. This means generally stores will have a single set size distribution or ratio for every product in the store. This certainly could be worse, but it could (and can) be better….

2) How do you maintain the planogram on the shop floor? I.e. how to ensure that the products on the planogram are always on the shop floor

This, on the other hand, is a major challenge for retailers. What good is a planogram if it’s not adhered to? For example, if a planogram states that a size XL should be on the shop floor at all times but it is missing due to inaccurate or slow replenishment/refill, and a customer who needs that size can’t find it, more often than not that sale is lost.

There are two ways steps that go a long way to fixing this:

- Use a more specific and data-driven planogram in the first place (What we’re going to explore now)

- Having a better replenishment process in the store. (Like this one)

How does AI change the planogram?

Manual maintenance and adjustment of specific planograms is rarely a realistic option for retailers, especially when it comes to specific size distribution for individual products and stores.

By utilising artificial intelligence and machine learning procedures, it is possible to automate this process to define a precisely optimised size distribution for all articles across the store.

Not only does this save an enormous amount of planning time, but it also addresses the ongoing dynamics in individual stores. The self-learning system adapts to possibly changing conditions and continuously optimises the plan.

- Produces automated planograms based on sales data

- Produces optimised planograms for individual products

- Produces optimised planograms specific to the individual store

- Constantly adapts and optimised the planogram based on new data

AI planograms in action with the Detego platform

If this all sounds theoretical, its not.

During the operational process in the store, Detego InStore also supports the store personnel at several occasions: The software offers two parameters that provide information about article availability at any time and therefore represent important KPIs:

- On-floor availability: The percentage of all available articles that are currently displayed on the sales floor

- Planogram compliance: Provides information on how well the planogram with its individual size distribution is implemented on the sales floor

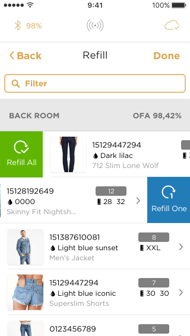

If one of the two parameters fall below certain threshold values, store staff needs to action: In addition to classic ERP systems, Detego InStore offers a finer level of granularity in the stores, by telling store staff that certain articles are available in the backroom but not on the salesfloor and therefore need to be refilled to comply with the predefined planogram.

Retailers benefit from a complete process for the planning and implementation. Another advantage: Refill advices in the app are sorted such that the search in the back room is made as efficient as possible by minimising walking routes.

With AI planograms, shelf space is used for top sellers and is not wasted on sizes that are rarely or never bought. With its self-learning components, the Detego platform for the store makes a suitable proposal for all sizes and facilitates implementation in daily processes – including relevant KPIs for measuring performance. And if a certain size is not available in one store, the platform offers an exact inventory view of surrounding stores – ready for click & collect.

Benefits for retailers:

- Individually optimised AI planogram per store

- Efficient use of shelf space according to bestsellers per store

- Guided processes: from planning to refilling

- KPIs to provide insights on operational excellence per store – in real-time

Benefits for consumers:

- High on-floor availability for the locally popular sizes

- Positive customer journey

- Overall increased article availability through exact inventory data on the entire store network – including reservation options