How using AI automation with RFID data accuracy can unlock unseen value for retail

AI pick lists – Intelligent Stock Replenishment Advice for Retail

(For an introduction to combining AI and RFID see this article)

When it comes to using Artificial intelligence (AI) and Radio Frequency Identification (RFID) in retail for process optimisation, the majority of use cases involve management or ‘HQ’ level decision making. These include automating functions such as store planograms and stock optimisation between stores.

However, AI can also impact retail on a much more micro and everyday level, actively assisting store staff in one of their most common daily routines –stock replenishment.

Using RFID and the information it collects from stock reads, we can produce AI pick lists to optimise and guide staff through the replenishment process. Not only are we combining RFID technology and AI algorithms to produce these pick lists, but existing RFID processes are already assisting staff. When you put all this together, replenishment become a walk in the park.

Let’s start at the beginning…

RFID-based Stocktake and Replenishment – The backbone of modern stock management

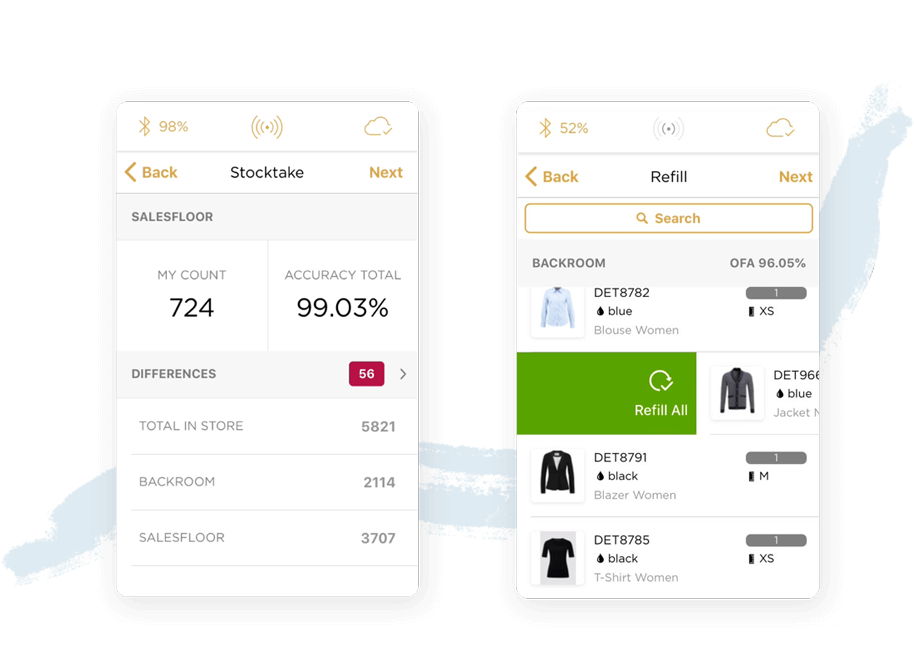

With RFID, store staff can do regular (often daily) cycle counts of the entire store quickly and easily. This is simply done by walking around the backroom and salesfloor with a handheld reader that counts items that are several feet away, using radio frequency. An RFID application or software, like the Detego platform, will then compare the actual stock levels of the shop floor with the desired counts (i.e., planogram), and tell staff exactly what needs to be replenished from the backroom.

So far, what has just been described has been entirely RFID-based and is the standard process for RFID in retail. This is already far easier and more accurate than traditional methods, not to mention the actual effect of the technology like higher stock accuracy and product availability. But why stop there?

Taking it one step further – AI pick lists for ‘mapping’ the perfect replenishment path

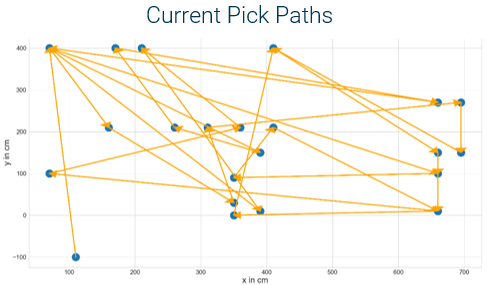

Normally, even with the support of RFID, the store staff are then left to fulfil replenishment by themselves, using the list provided by the application. These pick lists are often only sorted by product features such as name or price. Because back rooms can be quite large in bigger stores, or densely packed in smaller ones, the staff’s ‘pick path’ can be incredibly sporadic. This is made even worse in the case of new staff who don’t know the layout of the backroom by heart, or even experienced staff if stock has simply been moved around and updated with the start of a new season.

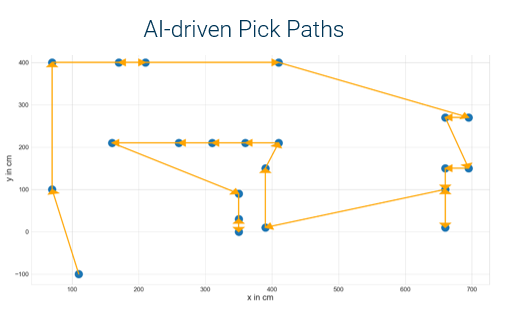

By utilising new tag localisation techniques, it is now possible to locate where items are in the backroom in relation to each other. This is done during the regular RFID stocktakes that are already taking place, utilising data mining and machine learning pipelines without any need for additional hardware or specialist tags. Using this information, we can create automated AI pick-paths that, using a mobile application, guide staff through replenishment and present the most efficient order to collect items in.

The above example is designed to present the quickest possible replenishment route for staff, so is solely using items’ distance from one another to calculate a pick list. However, AI pick lists can process the replenishment list in a number of ways, depending on what the store wants to focus on.

Replenishment paths could take additional factors such as product value or expiry date into account, alongside the location of the items. It would then look for items that fit this rule and are nearby one another in the backroom. For example, a pick list targeting on-floor-availability would group nearby items that are running low on the sales floor, so that these items are refilled first to speed up the replenishment process whilst also combatting loss of sales from out of stocks.

Leave a Reply