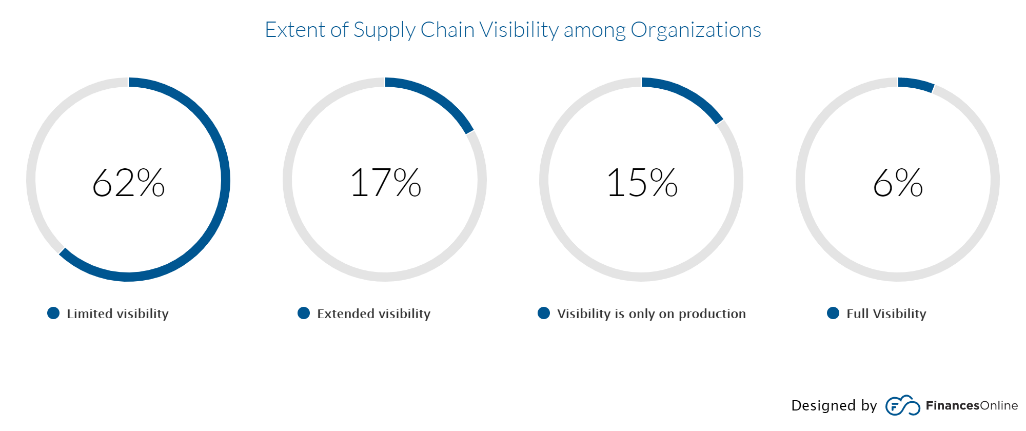

Complete Supply chain visibility was once an optional bonus for retailers, but in the modern industry it is becoming more and more of a necessity.

Whilst in the past, limited tracking of shipments in the supply chain was commonplace, in the modern environment with its more complex supply chains, delivery options and increasing customer expectations, retailers need to do more.

This isn’t just us saying so, retailers recognise this too. According to a report by Zebra Technologies, 72% of retailers are working on digitizing their supply chains in order to achieve real-time visibility.

What Is Supply Chain Visibility?

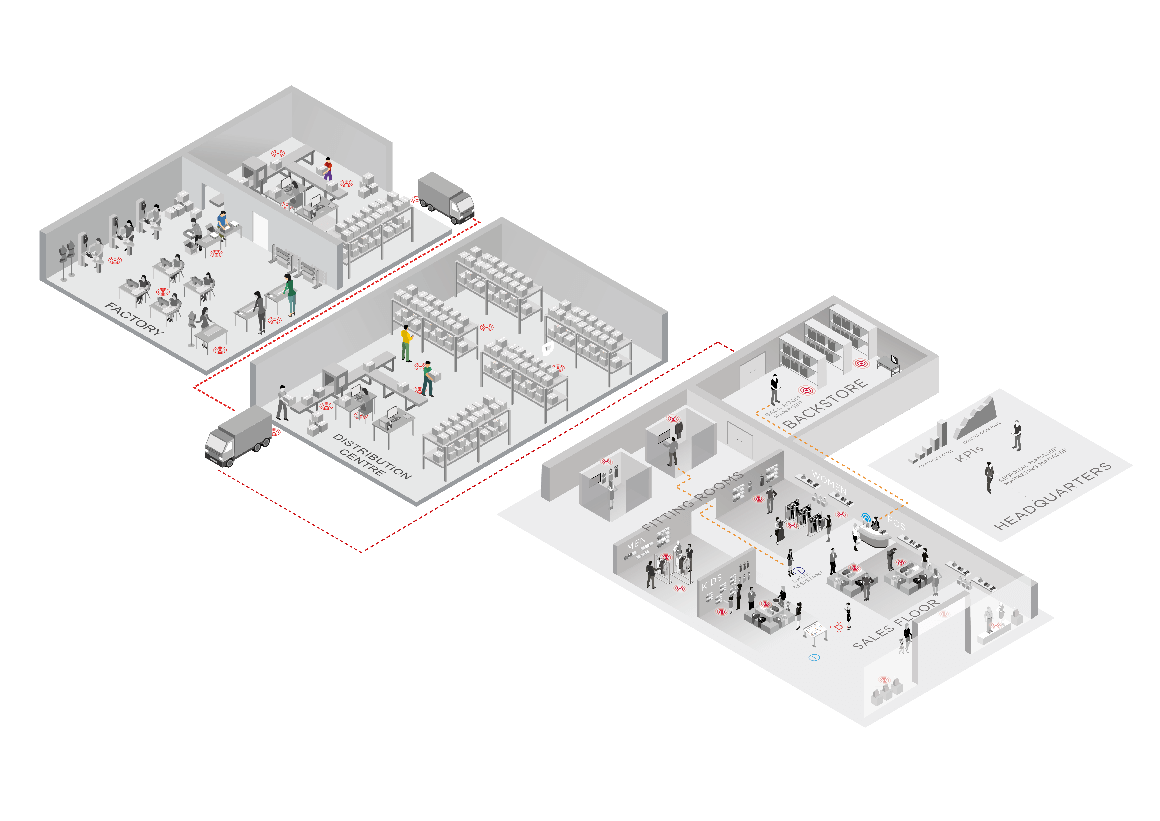

Having visibility means being able to accurately track products and shipments throughout the supply chain, from the manufacturer, to the distribution centre and finally to the store. Having this visibility prevents shipping errors, improves operational efficiency and allows retailers to leverage products to service their customers better.

Why Do Retailers Need Visibility?

Managing supply chains effectively is always a priority for retailers. But as these supply chains get bigger the challenge becomes more daunting. Visibility is needed to align such large operations, and this is before you add new pressures like omnichannel, traceability and online orders.

Additionally, supply chain visibility is arguably even more important in ecommerce than for pure-play brick and mortar retailers. Not only do you need to know exactly what stock the fulfilment centre has, but what stock it is due to receive and when. And since pure-play brick and mortar retailers are now few and far between , this now means that most retailers’ supply chains need to be more advanced and transparent than previously required.

This is before mentioning the divisive omnichannel word, which often requires even greater transparency and synergy between stores and distribution centres and includes multiple delivery options.

There are also more classic supply chain challenges that can be helped by achieving visibility. General inefficiencies and inaccuracies can be reduced by adding more checkpoints throughout the supply chain – particularly when these are done at an item level, and not shipment or carton level.

Adding this visibility also makes better communication between different stages of the chain possible, which leads to smoother operations. Having visibility at an item-level also makes traceability of items through the supply chain possible. This can make a massive difference in combatting supply chain shrinkage, and in some cases the grey market.

The ‘New’ Challenges:

Multi/omni-channel businesses – It seems like an age ago, but traditional retail supply chains went in one direction and to one place – stores. Now almost all retailers also run their businesses online meaning their they operate on multiple sales channels, therefore, their supply chains service far more destinations than before.

Multiple delivery options – A relatively recent challenge created by the growth of online and the already mentioned omnichannel purchasing options. Retailers want to offer their customers as much stock and as many purchasing options as possible, but without the technology to support it, this can cause problems. In an Accenture survey, respondents claimed that 31 percent of their Ship from Store orders triggered a split shipment.

Customer expectations – Customer expectations has shifted. In a 2019 report, it was found that Half of shoppers reported abandoning a purchase due to a lack of cross-channel buying options. This is a major impact on sales, and many retailers are starting to adapt to the change in expectations.

The Old Challenges:

Supply chain inefficiency – Supply chain inefficiencies and miscommunication through “Chinese Whispers” are costing UK businesses over £1.5bn in lost productivity according to analysis of industry data from Zencargo.

Supply chain shrinkage – According to the National Security Survey, businesses in the United States lose $45.2 billion through inventory shrinkage a year. Whilst retail stores make up the majority of this, supply chains still experience large amounts of inventory shrink, particularly when they have no visibility of products.

What are the benefits of having supply chain visibility?

-

Better customer service

-

Improved inventory control

-

Shorter cycle times

-

Smoother operational processes between stores and DC’s

-

Better data for more intelligent business decisions

-

Reduce out of stocks

-

Track and trace products

-

Offer effective omnichannel services and delivery options

How Do You Achieve Supply Chain Visibility?

-

Implement a system that works at an item-level (not whole cartons)

-

Accurately track products at as many points as possible during shipping

-

Inbound and outbound counts at every stage of shipping

-

Implement effective exception handling

-

Use a cloud-based system to integrate all stages of the supply chain and achieve as close to a real-time view of merchandise movement as possible

-

Send advanced shipping notices (ASN’s) so warehouses and stores now exactly what they’ll receive

-

Use this visibility to enable traceability of each item throughout its journey

The Detego Platform allows retailers to gain complete visibility over their operations

If you’re looking for a solution or partner to help achieve better supply chain visibility, consider our platform!

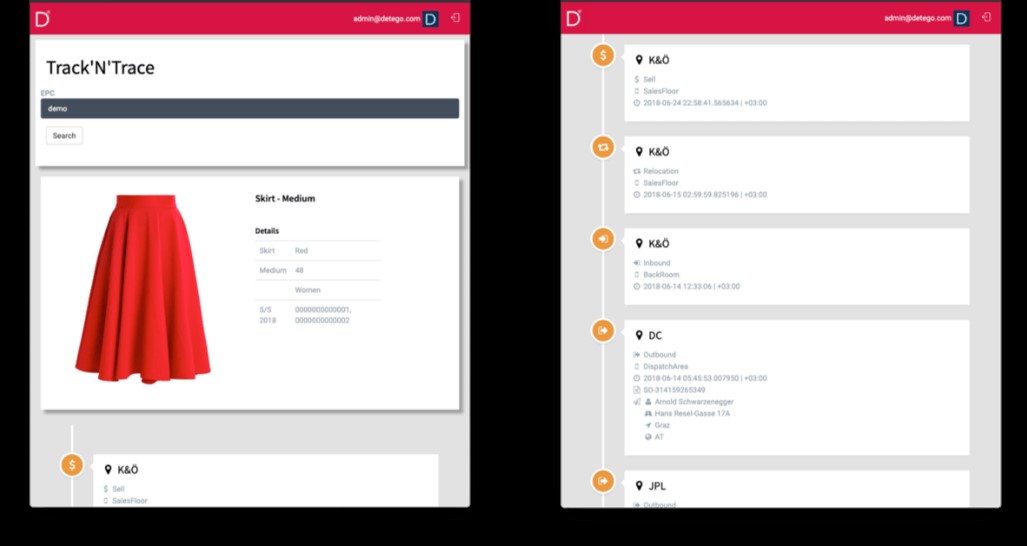

Using RFID item level-tagging, the cloud-based Detego platform gives each individual item a unique digital identity. Items are then tracked from factory to shop floor using radio frequency identification (RFID) methods. RFID makes this possible as inbound, outbound and even exception handling can then be done through RFID reads – which are fast, accurate and can be done without opening cartons.

Since RFID works on the individual item-level, the result of this is complete visibility of the supply chain. The platform utilises the IoT to create a complete overview of every single product in the supply chain, as its cloud hosted this can be close to real-time and is the ‘single point of truth’ for the entire business.

Want the latest retail and retail tech insights directly to your inbox?

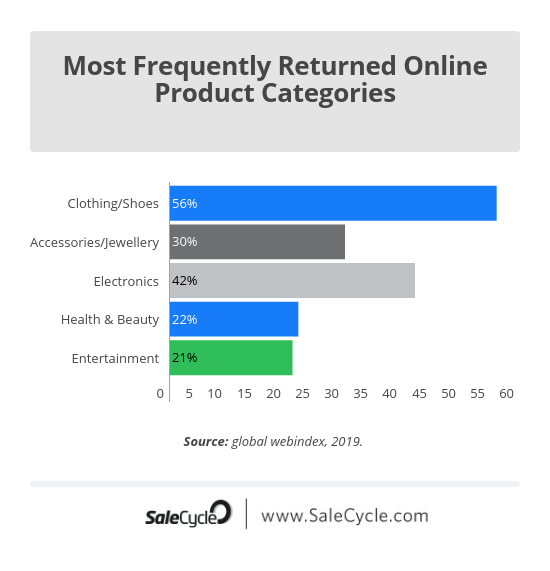

Online returns have been a challenge for retailers since the beginning of eCommerce. This is because of both their volume compared to normal stores, and the costs associated with processing them. In the wake of COVID-19, this problem could prove more critical then ever, as online becomes retailers’ singular sales channel. There is already early evidence of this, with preliminary data from Quantum Metric showing that eCommerce associated with Brick and Mortar retailers saw an average revenue weekly growth rate increase of 52%, and Nike Inc.’s digital sales went up by 36%.

The eCommerce returns dilemma

Online shopping is popular for a reason, but the convenience and choice of eCommerce comes at the price of not being able to ‘try before you buy’ for customers.

This simple difference is the reason online returns are so much more prevalent than for Brick and Mortar stores. In eCommerce the customers’ homes becomes the fitting room. And, just like any fitting room, products end up back on the shelves. According to Happy Returns, while shoppers return only 10% of what they buy in stores, they send back up to 50% of what they buy online.

This is compounded by customers accounting for this when ordering online. A survey from Barclays found that 30% of shoppers deliberately over-purchase and subsequently return unwanted items. Additionally, 20% regularly order multiple versions (often sizes) of the same item so they could make their mind up when they are delivered, all of which is facilitated by the retailer at great cost.

While it might seem logical to have stricter returns policies, or make customers cover the cost of returns, consumer expectations make this a risky strategy. According to the 2017 UPS Pulse of the Online Shopper survey, 68% of shoppers view returns policies before making a purchase. This leaves retailers with a catch-22 situation when it comes to losing out on online sales or losing profits from processing the inevitable returns that comes with those sales.

What are the challenges of retail returns?

So why are returns such a strain on retailers?

Cost of returns – First and foremost is the simple cost of returns. Since returns are in themselves essentially lost sales, the added cost of returning them, which according to CNBC is on average 30% of the purchase price, can heavily impact retailer’s margins.

Processing returns and reverse logistics – On top of this is the resources and effort of processing returns and getting the stock back available to be sold as quickly as possible. This reverse logistics can be particularly challenging and can result in returned stock not being available for purchase again for some time, often leading to out-of-stocks on the webshop. According to the Barclays report, 57% of retailers say that dealing with returns has a negative impact on the day-to-day running of their business.

Contamination concerns with COVID-19? – A unique and recent challenge, particularly for apparel retailers, is dealing with the potential contamination and contact of returned good with the COVID-19 virus. Initial research suggests that the virus can only survive on fabric surfaces for 24 hours, but for up to 72 on plastics like packaging. This will need to be addressed by eCommerce retailers who continue trading throughout the epidemic.

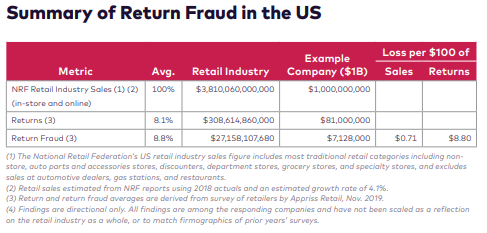

Return fraud – This is a challenge shared by brick-and-mortar stores. Fraudulent returns cost the US alone 27 billion dollars a year. This can involve the ‘returning’ of stolen merchandise for cash, stealing receipts to enable a false return or using someone else’s receipt to return unpurchased store stock. Naturally, using receipts for returns presents a risk, APPRISS found that receipted returns are more than twice as likely to be fraudulent as other methods.

How to reduce the impact of returns on eCommerce

So what options are there for retailers looking to tackle their returns problems?

- Reduce the likelihood of returns, without harming customer experience or sales: Include accurate and detailed product descriptions. Use uniformed/standard sizes where possible and provide a more specific sizing filter. Offer virtual ‘try-ons’ with augmented reality/3D imaging.

- Set clear and accessible rules regarding returns: Make sure customers know what and how they are allowed to return items, this reduces spending resources processing illegitimate returns.

- Improve visibility: Maintain a single view of stock with item-level inbound and outbound processes, this will also allow for online returns back to stores, and ship-from-store. Make this visibility accessible to your entire team and your customers.

- Improve efficiency of inbound and outbound processes: Utilise reliable & efficient technologies and automated processes like exception handling. One of the leading technologies for this is RFID, which prevents the need to open any boxes or packages as it can count and verify items without direct line of sight.

- Improve internal processes: Ensure returns processes (and supporting software) enables additional layers of merchandise management such as grading items based on quality and tracking when the item was returned.

- Counter Return Fraud: Verify legitimacy of returns as much as possible, best practise involves unique item-level validation like RFID or unique serial numbers.

- Ensure returned stock is safe to sell: Implement processes to ensure returns are not damaged in any way, implement a policy to account for safe handling of merchandise during theCovid-19 pandemic, either sanitising products or leaving them a set amount of time before adding back into webshop stock.

Using RFID tagging and looking to improve return processes?

NEW: eCommerce returns module

eCommerce/ DTC is increasing due to COVID-19. This causes an over proportional increase in returns which normally would require a ramp up of staff and equipment to handle the process – Detego’s new RFID enabled return process provides an approx 90% productivity increase.

Want the latest retail and retail tech insights directly to your inbox?

The Current Impact of COVID-19 on Retail

Supply Chain Chaos

Retail manufacturing and production have been heavily disrupted by COVID-19, particularly in China. In apparel and textiles, China is still the world’s biggest exporter. Even apparel manufacturers based elsewhere are often reliant on textiles imported from China. China being hit by COVID-19 and having to shut down factories and production has caused huge supply chain and production disruption around the world, with luxury retailers like Burberry and Prada being hit particularly hard.

As more and more countries are affected, supply chains may be disrupted further downstream. Larger distribution centres that service multiple countries could be most problematic, not only for fears of contamination but stores in countries that aren’t as heavily affected could have their product supply disrupted. On the other hand, since China was affected by the pandemic first they may recover first, so by the time other countries are beginning to come out of lockdown and preventative measures, this supply bottleneck may well be clearing further upstream.

Shutting of physical stores & reduced footfall

Across the globe brick and mortar sales are suffering. Stores are either being closed on government orders or simply being closed by the retailer to protect staff and public. The stores that remain open are being hit by the heavily reduced footfall as the majority of the public attempt to avoid unnecessary social contact.

The effects of this on revenue have the potential to be fatal. Lost sales are damaging enough, but when you factor in continued overheads for stores like rent, wages and inventory, it is a dangerous situation. Only time will tell how damaging these effects will be on retailers across the globes, with the main variables being:

- How long areas remain affected & stores are closed for.

- To what extent a retailer’s eCommerce operation can pick up the slack (more on this below)

- How big or financially stable the retailer is prior to the epidemic – large tier 1 & 2 retailers may be able to shoulder the burden for longer than their smaller or independent counterparts.

Spike in Online Sales

With many stores closing and consumers avoiding most of the ones that remain, it’s no surprise there has been a spike in online shopping due to COVID-19. This is exemplified by the eCommerce kings Amazon who are taking on 100,000 extra staff across the US as it tries to keep up with a surge in orders sparked by the pandemic.

Whilst its good for both the retailer and the consumer that most brands now operate both on and offline, the sudden shift in proportion between online and offline sales may cause retailers problems if they struggle to keep up with demand. These issues include fulfilment centres not coping with increased demand and the amount of returns that come alongside online orders.

The other major consideration for many retailers is the typically smaller margins on eCommerce orders compared to brick and mortar sales, meaning that they may not be able to rely on their eCommerce branch to survive for too long.

Future Considerations

So, what might a post-COVID-19 retail landscape look like? Will retailers take lessons from the crisis and bolster their infrastructure so they are more prepared for similar events in the future? Or once the dust settles will this be counted as a freak event and forgotten about? Here are possible considerations for retail life after COVID-19.

Continued advancement of e-commerce

This was bound to happen even without the pandemic, but COVID-19 may just have accelerated, or at the very least highlighted, the growth of online shopping and its advantages over physical retail. It is likely that retailers with a strong eCommerce offering will come out of the slump in a much better position.

For multi-channel retailers who had to rely on their online sales more than ever during COVID-19, evaluation into their eCommerce operations, particularly at their efficiency and smaller margins, are very likely. This may take the form of bolstering their supply chain technology and distribution centres, to increase efficiency and reduce running costs to see better margins in the future.

Diversifying manufacturing facilities

Steps have been gradually made in this area even before COVID-19, but in the aftermath of the pandemic, this may be a real concern for retailers and manufacturers. The problem isn’t China, or anywhere in particular. The problem is having such a heavy reliance on a single market, which then becomes a single point of failure for the business. Profit margins will always be a priority, but more cautious retailers and manufactures may look to diversify their production operations to be less reliant on a single region in the future.

Source-to-consumer traceability in supply chains

This is another area that was already a growing priority for many retailers. In the aftermath of COVID-19, it is likely to be even more of a concern, for both retailers and consumers. Not only does traceability help create smoother operations in the supply process, but it can offer assurances to consumers who may have growing concerns about where their products are sourced. With item-level traceability being where the industry is headed, consumers will be able to judge for themselves that their food, clothing and other things they bring into their homes is safely made and transported.

Automated warehouses and supply chains

The other element of the retail supply chain and distribution process that may change in the future is a heavier reliance on automation. This will make supply chains and distribution centres more robust, so able to withstand increased pressure. Automating processes like exception handling also means DC’s can run faster and with a leaner workforce.

Why may retailers look at automating supply chain operations in the future?

- More efficient – can deal with larger quantities of goods

- More accurate can deal with larger demand without creating bottlenecks

- Takes the reliance away from human resource constraints

Self-service stores and cashierless checkout

Finally, could the coronavirus be a catalyst for increased investment in self-service technology like cashier-less stores? We’ve seen retail giants like Amazon and Sainsbury’s explore these initiatives, but they have yet to be adopted on a large scale. Could that change? It may feel like a knee-jerk reaction to invest in technology that supports reduced human interaction but, particularly for supermarkets, solutions like Marks and Spencers’ mobile scan & pay could alleviate pressurised checkout lines.

Conclusion

We’ve gone over the major concerns for retail, the possible impact they could have, and the potential knock-on effects of the COVID-19 pandemic on the retail industry. But the fact is no one really knows. We are in uncharted waters, and for now, retailers are just struggling to ride the wave to the other side.

What we do know is this will pass. The main question for retailers that will determine the severity of the pandemic’s impact is when. Whilst this isn’t the second ‘retail apocalypse’, it is more than likely that the retail landscape that comes out of the coronavirus crisis may be very different from the one that went into it.

Want to learn more?

Apparel Retail’s New Normal: COVID-19 Impact and Future Trends

Webinar

Now stores are facing new social distancing guidelines, the formula for customer experience has changed. With reduced foot traffic and higher levels of eCommerce, the digital evolution of the retail store is now or never. Join us on the 16th of June as we dive into the physical and digital transformations behind retail’s ‘new normal’.

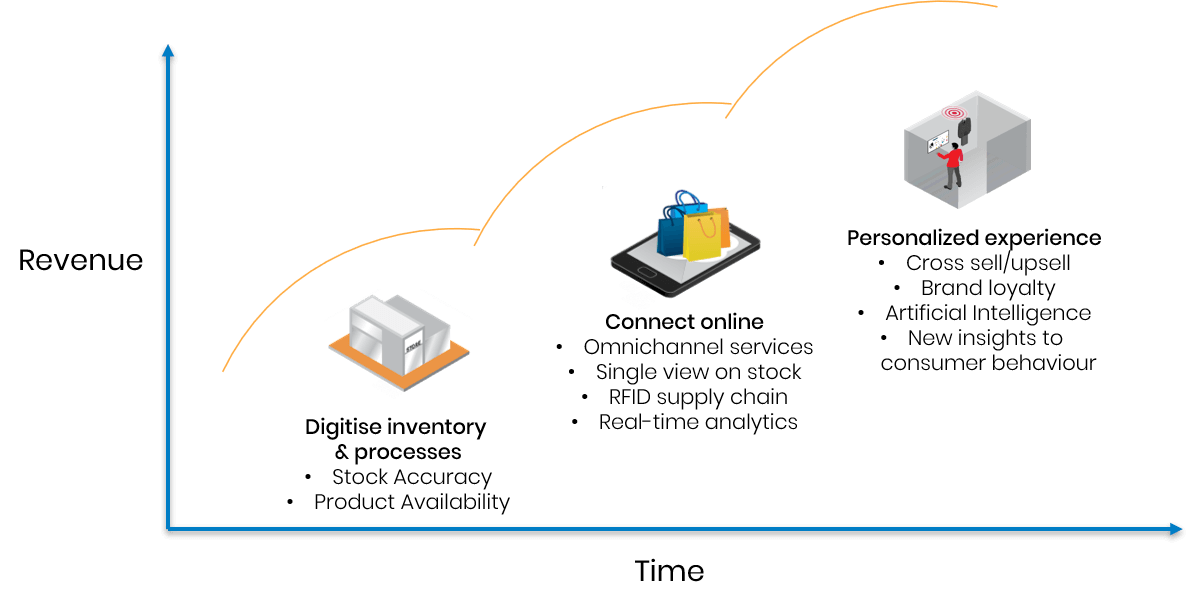

When it comes to digital transformation, RFID (Radio Frequency Identification) has been the hype in retail for several years now. It has, however, been a bumpy road to success. In the past, stories of failed implementations and botched rollouts were far too common and kept many retailers from taking the plunge. Thankfully these days the picture is much more encouraging. We are now spoilt for case studies and examples of retailers having enormous success with the technology to digitise their inventory and processes for the modern retail environment.

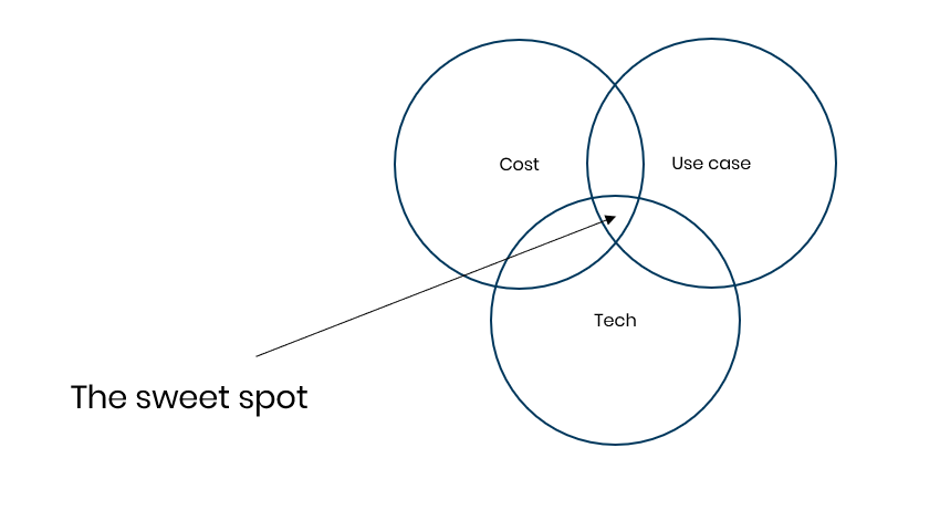

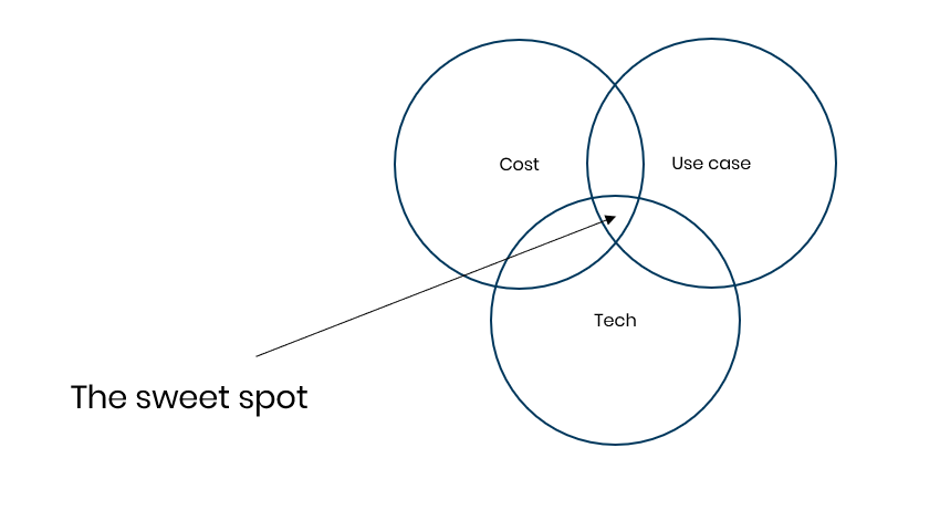

So, what makes the difference between failure and success?

Ultimately it comes down to a combination of knowledge, technology and price. Improvements in all three of these areas have evolved the technology into a vital component of any digital transformation journey in retail. But as with any transformative project, getting the detail right is vital. The approach to implementation and suppliers you choose to engage with will have big implications on ROI.

A best-practise approach is easier said than done, so you need to surround yourself with a team of experts who have skin in the game and ensure the solution you choose to implement has the capabilities to lead your digital transformation for years to come.

Our recommended 6 steps to digital transformation with RFID:

1. Understand the problems you want to solve and clearly define the KPIs

The first step in any new tech investment is to be sure that you have clarity around what problems you are hoping to solve. This will often require some hard-hitting questions and honest auditing of current processes and data to understand where you and your customer’s biggest pain points are. Customer feedback surveys are always a good way to gain insight into this.

What common retail problems can RFID solve?

- Stock inaccuracy leading to out-of-stock situations

- Poor product availability on salesfloors and webshop resulting in lost sales

- Labour costs and operational inefficiencies

- Reduction in excess/safety stock

- Inventory visibility and supply chain traceability

Luckily, these problems all have clear KPIs related to them and can be used as a great measurement tool to understand your current position and build a business case for the investment.

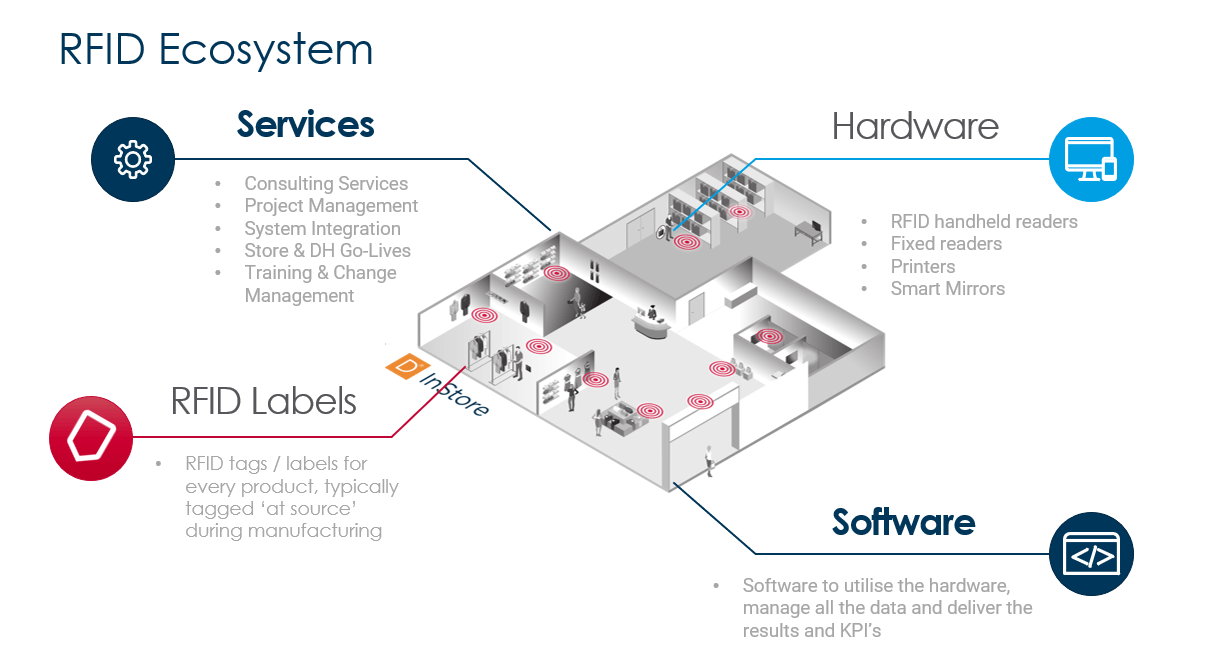

2. Choose a software partner that will help you achieve more

Once you have clearly defined RFID as the technology you want to implement, it is then vital to choose the right partners to go on your digital transformation journey with. Within the RFID market, there are generally three partner types – hardware, labels and software. The software component is the most important aspect as this must be able to process all the data, integrate with existing systems and empower employees with user-friendly applications to improve daily processes. Choosing the best-suited partners will make all the difference to ensuring you have a scalable and future proof solution for the next 5+ years.

What to look for in an RFID software partner?

- Credibility in the market – do they have proven RFID deployments with reputable brands in your sector?

- Future-proofed services – do they have a product roadmap that inspires innovation and constant improvement?

- Scalability and flexibility – does the solution fit your business needs and implementation roadmap?

- Industry expertise – do they have deep industry knowledge to understand your specific business requirements and help you think through these challenges?

3. Trial the solution, prove the business case

Any digital transformation project requires buy-in from multiple departments and key decision-makers. The best way to achieve this is to prove the business case in a live retail environment. This is done through a ‘Pilot’ process whereby the solution is tested in around 3-5 live stores, allowing for the critical KPIs to be assessed and to gain a clearer understanding of the implications for store processes. With SaaS-enabled solutions, this process can be done more efficiently through the use of cloud-hosted mobile solutions, essentially making them ‘plug & play’.

What does the pilot process involve?

-

Tagging party of all items in Pilot stores with RFID labels

-

Product Master Data uploaded to SFTP (or FTP)

-

Training of store associates

-

Use of handheld readers and mobile app to perform daily store operations

-

Daily KPI tracking to analyse results:

- Improvement in stock accuracy

- Improvement in on-floor availability

- Increase in sales

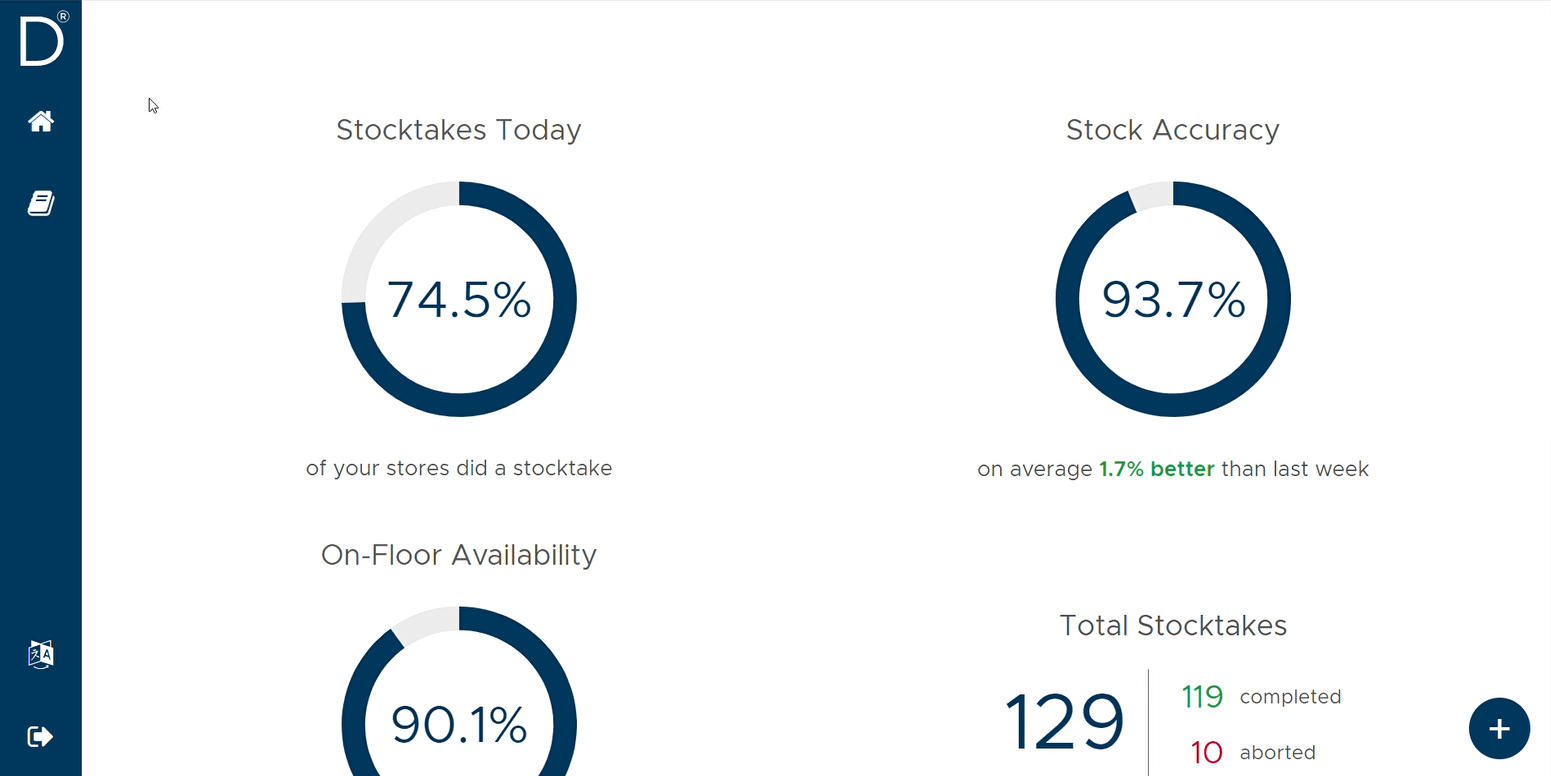

4. Store rollout with speed for immediate ROI

Although it seems attractive to enable all of the features and RFID-enabled services in one go, and undergo a digital transformation overnight, the reality is often different. Instead, retailers should approach implementation in phases to manage the changes in process and IT requirements. A best-practice approach to RFID implementation should focus on improving the fundamental processes that will bring the most immediate ROI to the business. These processes include stocktakes and replenishment to significantly increase stock accuracy and on-floor availability within stores. Improving these two KPI’s generally results in a direct sales uplift of 5-10%. From there, you can re-invest returns back into the continuous enablement of RFID throughout your business.

What elements are most critical to a successful store rollout?

-

Speed and ease of implementation

- New innovations such as Smart Shielding removes the need for physical shielding installations – saving time and money.

- SaaS-enabled platforms allow for scalable pricing models and cloud-hosted solutions.

- Open APIs allow for easy system integration with ERP

-

Support services

- Training to educate staff on the changes in daily processes

- Customer success and support to maximise the use of the software

-

Change management leadership

- Ensuring you have a dedicated team to oversee the rollout

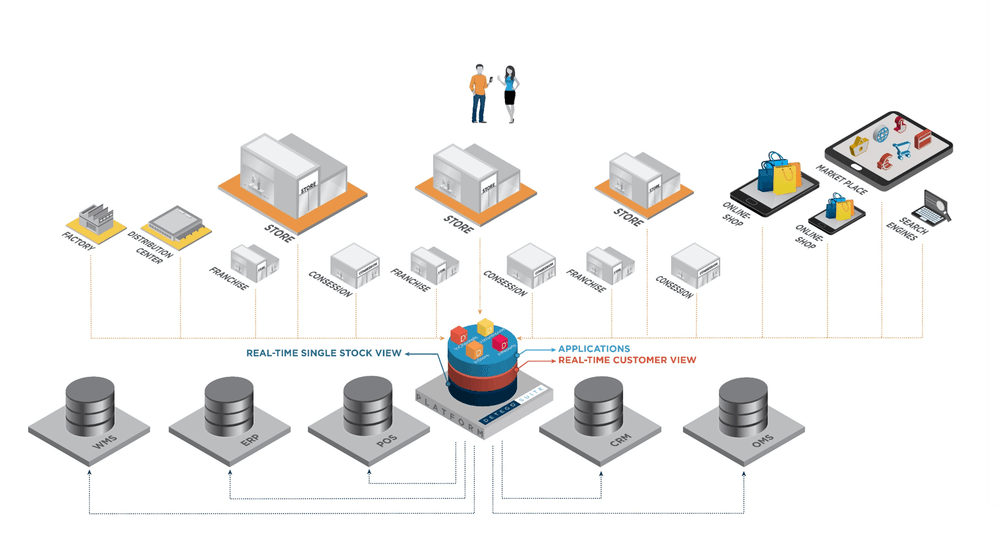

5. Full omnichannel enablement

After securing the foundations of stock accuracy and on-floor availability in stores, the next step is to connect the online and offline business. Omnichannel services such as click & collect (aka BOPIS) and Ship-From-Store are expected in the modern retail environment as consumers demand to shop anywhere, anytime and any way they want. However, it’s important to ensure you can deliver on these retail experiences so that customers don’t end up disappointed. Enabling this requires connecting inventory from your store networks with your distribution centres and webshop to create a single and transparent view of stock.

What’s required for Omnichannel retailing?

- Transparent view of stock across all stores made available to the online store

- Automate warehouse processes with RFID tunnel and outbound processes

- Offer new services such as click & collect, ship-from-store etc.

6. Unlock the true power of RFID with new retail experiences

Stock accuracy, product availability and omnichannel services are synonymous with RFID in retail and should always be the focus of any digital transformation utilising the technology. However, there is also an unlimited amount of untapped data and potential that is a sitting gold mine once you have RFID implemented throughout the supply chain. New solutions for consumer engagement and artificial intelligence engines can now be utilised to provide new services, experiences and insights for retailers and consumers alike.

What new innovations can be enabled?

Interested in discussing your RFID Journey? Talk to the experts.

At Detego we know retail and we know RFID. This combination has enabled us to develop the most innovative RFID software solutions on the market, alongside major global fashion brands. With RFID now on almost every retailer’s roadmap, we have the answers for any step of the journey, anywhere within your operations.

Everyone has to start somewhere, which is why we have out-of-the-box solutions to quick-start your RFID journey. Alternatively, if RFID is well and truly ingrained in your business, then talk to Detego about how we are using AI and innovative new practices to take real-time decision making to the next level.

Want the latest retail and retail tech insights directly to your inbox?

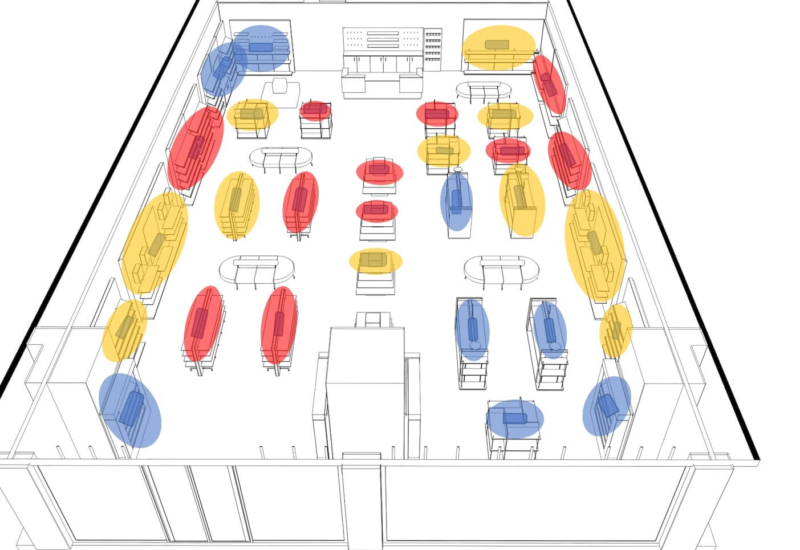

Visual Merchandising’s Data Problem

Visual merchandising is one of the ‘dark arts’ of retail. For the uninitiated, it’s the practice of designing visually appealing sales floors and store fixtures that attract customers and ultimately sell the products on display. It’s a subjective and artistic means of delivering a concrete KPI – sales.

One of the challenges of visual merchandising is data, experimentation & design is all well and good, but not if you have no way of knowing what does and doesn’t work. Sales data is always a good place to start, but there are so many other factors at play that it’s often unwise to attribute visual merchandising to an increase or decrease of sales to a single product. You have to go one step further…

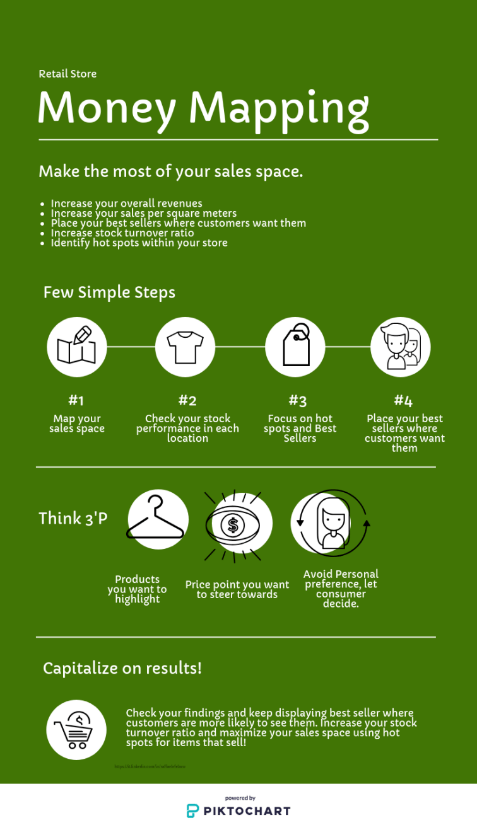

What is Money Mapping?

So, how do you measure the sales performance of a store based on its layout and design?

First, you map out the sales floor with the exact location of products. Then you break the map of the store into ‘zones’, typically around certain fixtures, shelves and displays. These zones can consist of several different items, grouped by either category or style depending on the design of the store.

You then collate the sales of every item in this zone and compare it to others in the same store. The result? An impression of shop floor sales broken down by areas of the store.

This is called ‘Money Mapping’ and allows retailers to visualise and analyse which areas of a store are ‘hotspots’ and which are ‘cold’ in terms of sales. This gives an initial view of which areas and fixtures are selling products and which aren’t.

To account for other external influences on sales, best practise is to swap items between fixtures or observe a ‘money map’ over a long time, as collections and merchandise changes between seasons. This way, if the localised sales data remains relatively similar even after products have rotated, then it’s clear the design or locations of the fixture is having an impact.

What are the benefits of Money Mapping?

- Insight on consumer experience

- Provides valuable data for visual merchandisers

- Breaks down areas of sales floor by sales performance

- Can be used to optimise store layout

- Drives Sales

- Can compare Product Placement & Visual Merchandising

- Can be used to conduct A/B tests

This all sounds great, so why doesn’t every retailer and every store do this already? The simple answer – the process of matching the sales data to specific locations on the sales floor, manually for every item and every store, is logistically a big ask. This means, if this can be done at all by visual merchandisers, it can only be done in a small number of stores.

How does AI change money mapping?

So how can we solve this data problem for visual merchandisers and make ‘Money Mapping’ easier and more accessible for retailers?

The first issue is having an accurate map of a store which includes exactly where every single item is sold from. Traditionally this would have to be done manually, and then have the sales data of items cross-referenced with their location in a store.

The solution: Using RFID (Radio Frequency Identification) and AI localisation techniques, we can now create a map of a store as part of the daily or weekly stock count.

This is done by adding ‘reference’ RFID tags into the store. Small tags just like ones that go on products are placed on fixtures and walls in the store. Because these never move, we can use the signal strength (relative to the fixtures) from stock counts to map exactly where items are in the store and what items they are grouped with.

This location info is then integrated with data from point of sale to generate an automated Money Map of a store, as part of the regular reporting and analytics function of the store. This can be done for as many stores as desired. With the data collection automated, visual merchandisers can focus on using the data to optimise product placement and store design across stores.

With larger data sets to work with, this also opens up the potential for more detailed analysis and experimentation such as A/B testing product combinations and store layouts!

What’s the process for AI Money Mapping?

- Attach reference RFID tags to walls and fixtures within the store

- Perform regular RFID stock takes as normal

- Software uses machine learning to ‘map’ out item locations within the store

- Integrate point of sale data with RFID software

- Software produces ‘heat map’ of the store based on sales

- Visual merchandisers can use data to inform strategy and measure results

Conclusion

Visual merchandising is a subtle but valuable process for retailers. Done properly it has a huge impact on both sales, customer experience and brand image. The only problem with this is visual merchandisers often don’t have enough data to measure performance and identify where their attention is needed most. The data they can collect is either time consuming, expensive or inaccurate.

Artificial intelligence changes the game for visual merchandising. By utilising RFID tags and Machine Learning, it is possible to ‘map out’ the location of items in a store, and more importantly, the sales distribution of the shop floor. These ‘Money Maps’ tell visual merchandisers what areas of the sales floor are ‘hotspots’ for sales and which are underperforming. Using this data, they can then focus their attention on improving the design or layout of certain areas.

Additionally, with this data stores can look to leverage their sales hotspots either by prioritising the best locations for best-sellers, high-value items or items that are due to go out of season.

Either way, AI-enabled Money Mapping is another important evolution in retail data and analytics. Providing retailers with unprecedented insight into exactly what goes on in Brick and Mortar Stores.

Want the latest retail and retail tech insights directly to your inbox?

What is a Smart Fitting Room?

Smart fitting rooms consist of an interactive touch-screen mirror connected to an RFID reader and a motion sensor. They sense when customers enter the fitting room, and sense what items they have brought in with them by reading their RFID tags. They then assist the customer throughout the fitting room process, giving them information on products and calling for assistance if required. In simple terms, they allow consumers to experience the same benefits they get from online shopping whilst in the fitting room, as well as let them request items be brought directly to them.

What does a Smart fitting room do?

- Detect movement and presence of a customer

- Identifies which item the customer brings to try on

- Displays additional product information

- Provides availability information to the consumer

- Shows product recommendations that would complement the currently selected style

- Provides additional services such as Call for Assistance or Call for different products / colors / sizes

Smart fitting rooms have existed in the fringes of the retail technology space for a number of years. The interactive mirrors certainly capture the imagination, but they’ve only really existed at trade shows and in concept stores rather than out in the wild. It’s fair to say the technology was in the category of interesting and fun but not really taken seriously. Fast forward to 2020, and we have just seen the first major commercial use of smart fitting rooms, in a truly digital, experience-first, award-winning store.

What makes up a Smart Fitting Room?

- Framed Mirror

- RFID Reader & Antennas

- Motion Sensor

- Touchscreen Display

- Internet Connection

- A store that is using RFID item-level tagging

So, now is the time to start paying attention to Smart Fitting Rooms. But for those looking at the technology, either for the first time or with fresh interest now that solutions are live in the market, the business case might be a concern. In this article, we will break down exactly what a smart fitting can do, and what kind of value they offer for retailers, customers and retail profits.

What are the business benefits of Smart Fitting Rooms?

Improving Customer Experience

As a customer-facing technology, we’ll start with the most obvious (yet qualitative) use of the smart fitting room – an improved customer experience.

Rather than taking this for granted, however, let’s dig into how, why and even if smart fitting rooms offer a better experience for customers. Having a mirror automatically detect and display item information is nice and will wow customers (at least to begin with) but doesn’t really add much more value than an interactive screen that can scan products barcodes or even a product QR code.

What sets smart fitting rooms apart from these solutions are the interactive options and how they support customers. This includes offering additional and related or ‘frequently bought together’ items, information on exactly what is available in the store (using the real-time stock view RFID provides) as well as being able to request items be brought directly to the fitting room. These options being built directly into the mirror that customers already use will both delight customers and make the fitting room experience more convenient.

How smart fitting rooms benefit the customer:

- Shows different product combinations

- Makes product recommendations

- Article availability check

- Shows full range of articles to browse through

- Additional information, videos, social media integration

- Customer-friendly fitting (Article-Bring-Service)

- Enables digitally supported purchase decisions

- Direct reservation or ordering of articles

- Different delivery options (delivery to home address, from another store, etc.)

The economic value of customer experience:

Increase Sales

‘Customer experience is king’ has been a favourite tagline of innovative retail for some time. While it’s probably true and certainly sounds good, when it comes to the business case of new technologies you really do need to look at revenue. In terms of the customer, that generally means sales. So, what effect do smart fitting rooms have on sales? Other than more tenuous effects like bringing more customers in to the store, Smart fitting rooms increase retail sales in two ways:

Combating Lost Sales

Fitting room conversions is a self-explanatory if unfamiliar term for brick and mortar stores. That’s because as a KPI retailers have never had any way to measure or track this (more on this later). But fitting rooms are absolutely pivotal to apparel sales.

According to The Retail Doctor, shoppers who use dressing rooms are 70% more likely to buy versus those who don’t. It’s easy to see why, as customers have already decided that they like the item and want to purchase it, so fitting rooms become a question of making sure, and finding the right size.

It’s finding the correct size where most fitting rooms sales are lost. If a customer needs a different size, they will have to leave the fitting room and come back. Studies prove that this can have a major impact on sales, as 50% and 21% of people say they will sometimes and every time respectively leave the fitting room and the store if they were looking for assistance to change colour or size of an item and can’t find anyone.

This is why helpful fitting rooms assistants have such a big impact on sales, customers who receive assistance in fitting rooms make twice as many purchases as those who don’t. Smart fitting rooms address this issue, showing customers what other sizes are available and letting them request different sizes be brought directly to them. This allows stores to have assistance on hand (they are notified via a mobile application) without needing a permanent fitting rooms assistant, which is not feasible for many stores.

Increasing basket size with in-store cross-selling

The other sales driver of smart fitting rooms is having product recommendations made based on the items brought into the fitting room. This brings cross-selling common in e-commerce to the brick and mortar experience. Whilst these can be done as an endless aisle (so the entire product range of a store) the better way is to only offer items that are available in the store (using the stock visibility RFID provides). Much like requesting additional sizes, customers can request to have items that catch their eye brought directly to them. This can drive sales significantly and has been seen to increase fitting rooms basket size by 100% in initial studies.

New Data and Insights For Stores

The lesser-known use case of smart fitting rooms is the data and insight provided about the customer experience. It’s often said that compared to e-commerce, retailers have next to no data about what actually happens inside their stores. Other than what gets sold, they’re blind. In an industry as competitive and fast-moving as retail, this lack of analytics can be fatal.

We’ve already established how important fitting rooms are to apparel sales, so it seems that collecting and analysing data from them is a no-brainer. Traditionally however this hasn’t been the case, but with RFID and smart fitting rooms, retailers can collect that data in a non-invasive way.

What kind of insights are provided by smart fitting rooms?

- Item Conversion rate – How often are items selling (or not selling) immediately after being tried on in a fitting room?

- Fitting baskets vs shopping baskets – Most tried on vs most sold

- Number of items per session

- Session duration

- Recommendation conversion rate – How often are items recommended, requested and then sold?

- Need assistance use – How often are staff called to the fitting room using the mirror?

- Staff response time – How long does it take for store staff to react to customer requests? (gaining actionable insight to customer experience)

Conclusion

Consider the context of interactive displays, AR, VR and even RFID tables. Smart fitting rooms are both a part of this space and completely apart from it. This is because fitting rooms aren’t new, they are and always will be a part of the apparel shopping experience. Rather than adding a new element to the shopping experience like VR for example, smart fitting rooms are improving an integral (and for many, unpleasant) part of the customer experience.

In other words – it’s an evolution, not a revolution.

Whether retailers embrace this evolution will be decided in the coming years, now that smart fitting rooms are finally out in the wild. Perhaps even more crucially, especially when talking about business case, now smart fitting rooms are out in the market we will begin to see data and results that will prove the value once and for all. As early innovators of the technology, we can’t wait.

Want the latest retail and retail tech insights directly to your inbox?

Radio frequency identification (RFID) has become established as a dominant force in the apparel industry, with the technology finally approaching mass adoption after years of threatening to.

The technology involves tags or “labels” that emit a small radio frequency, allowing radio stock counts that are both highly accurate and incredibly fast compared to traditional methods. The result of this is a very up to date, or even real-time, view of stock. The main use cases responsible for the technology’s success include the increased process efficiency, superior inventory management and the enablement of seamless omnichannel services.

That’s the story of RFID in apparel, but what about other retail industries? After years of technical roadblocks that have kept the technology out of other markets, the technology has matured to a point where new industries are RFID-viable for the first time ever. The beauty and cosmetics industry is beginning to take notice of RFID, and perhaps now food retailers should do the same.

Why? Because modern RFID is so well positioned to tackle the food industry’s unique challenges, like optimising inventory, minimising food waste and increasing the traceability of the supply chain.

Whilst this sounds great, the limitations of the technology that we mentioned earlier have historically meant RFID just wasn’t viable for the food market. As well as liquid and metallic products traditionally interfering with the RFID signals, the food industry’s drastically lower average article price compared to the apparel industry were significant roadblocks. But this changing…

Mature RFID technology is ready to take on the food industry

RFID is reaching a level of maturity that means the previous barriers to entry for the food industry are starting to disappear:

- The price of individual RFID tags has fallen significantly, making it viable for more and more food products.

- RFID tags have become smaller – so it’s now possible to label even the smallest items.

- More advanced tags now exist that work on metal and liquid products

- Durable tags that survive high and low temperatures and even microwaves are now available, meaning all kinds of food packaging can be tagged with RFID.

Because of these changes we are already seeing the first steps of RFID breaking into the food industry, with RFID-giant Avery Dennison beginning to operate in the market and last year the first-ever blockchain beef shipment taking place using RFID tagging, providing a potentially industry-changing level of traceability and assurance only possible through RFID.

Superior inventory management for efficient operations.

The first major use case for RFID in the food industry is one already tried and tested in apparel – superior inventory management. Replacing manual stock-keeping methods with fast and highly accurate RFID processes gives retailers a reliable and up-to-date view of their entire stock. Whilst having a clear view of store inventory is highly beneficial for any retail business but for the food industry, where items have to be managed and monitored much more intensely, an RFID system could cut shelf life labour costs by up to 50%. Another major impact of the 99% stock accuracy RFID provides is the reduction in inventory sizes due to not needing extra ‘safety stock’, this could have a major economic effect for food retailers and would also stop inventory shrinkage from expiry dates. Leading us to our next major use for RFID in food retail:

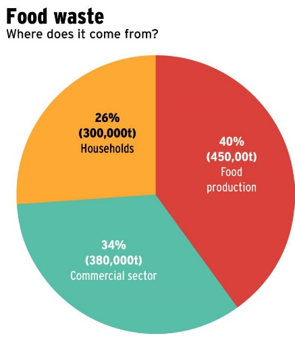

Reducing Food Waste

Food waste is a massive problem. Every year in the UK alone 18 million tonnes of food end up in landfill, Around 1/3 from producers/ supply chain, 1/3 from retail and 1/3 from households. Not only is this an environmental and ethical issue, but for the food industry itself, this sees huge amounts of capital literally wasting away.

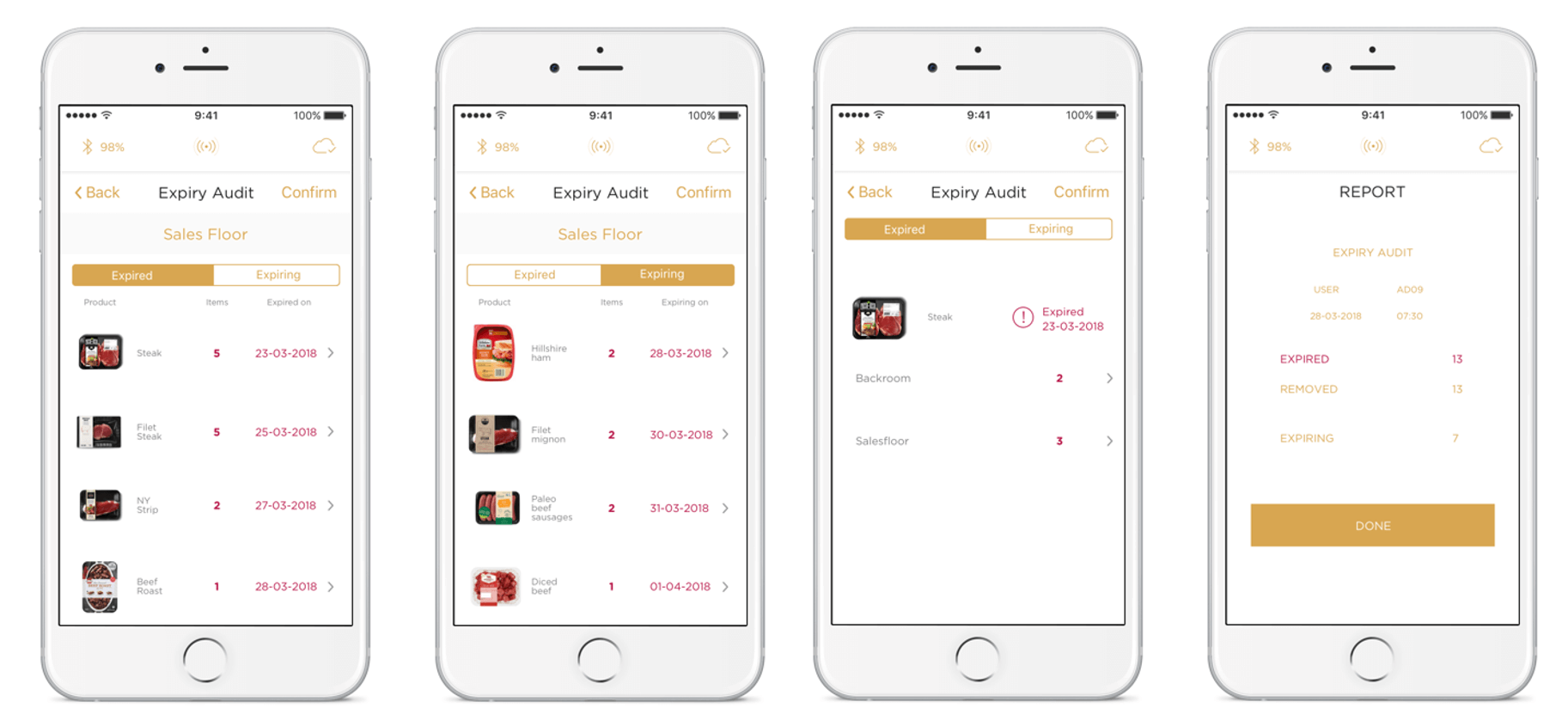

When it comes to retail, fresh produce and waste due to shelf-life is a unique issue to the food industry, but one RFID (and an effective RFID platform) is well suited to manage. Expiry dates result in a huge amount of food waste in the commercial sector and are also very labour intensive to manage on the shop floor.

So how might RFID solve this problem? The benefits that the accurate and item-level view of stock RFID provides has been well documented in the apparel sector, but with the food industry, this real-time view of stock will be even more valuable. An Internet of Things platform (giving individual physical objects a unique digital identity) designed specifically for use with food products would not only be able to monitor and maintain stock levels on shelves but could monitor the expiry date of individual products, alerting staff when items are nearing expiry or need to be marked down.

A fully Visible and Transparent Supply Chain – for consumer satisfaction and better handling of product recalls.

The final major use case of RFID for the food industry is the traceability of products through the supply chain. Whilst other retail industries get value out of this in terms of warehouse efficiency and smooth operations between distribution centres and stores, the food industry is an industry where traceability of products is a major concern, for consumers just as much as retailers. People are increasingly concerned with where their food comes from, and suppliers and retailers could look to take advantage of RFID traceability and even utilise new blockchain methods alongside this to offer their customers assurances and gain the trust of consumers. We are already in the very early stages of this having already seen the first blockchain beef shipment take place, giving consumers 100% traceability and visibility of where their produce comes from.

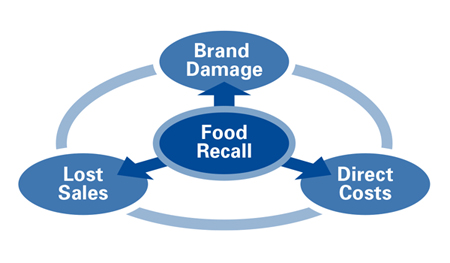

On the other end of the food traceability issue is food recalls. Product recalls are an unfortunately common problem in the food industry, costing the industry an estimated $55.5 billion a year. A recent example of this being the major recall of humous products across the UK due to salmonella. These have a huge impact on the industry, not only economically but also on brand reputation. RFID’s ability to accurately trace individual items across an entire supply chain could prove invaluable in such an event. Having complete accuracy would allow food suppliers to pinpoint exactly where the issue occurred and easily track where all other products from the compromised location were sent, allowing for fast and efficient recalls. This would also potentially reduce food wastage due to over-recall and increase consumer trust in the retailer.

Conclusion

So, the food industry has several challenges that RFID has been proven to solve and the technology has gotten to a point where it is viable among the much more diverse and complicated range of products. The only thing that may hold it back is the cost. Whilst the price of tags has dropped significantly, the price point for food products is far lower than in apparel. This may prove a barrier for tagging some food items, at least initially. Fresh products like meat and fish (and potentially some fruit and veg) however have both a high enough price point and a limited shelf life meaning managing them with RFID could prove hugely beneficial. The food industry is a new frontier for RFID, and time will tell just how well it does in the market. But make no mistake, in the coming years we will see it attempted, and the success of the technology in the industry will be decided, one way or another.

Want the latest retail tech insights directly to your inbox?

Radio frequency identification (RFID) has had a fairly long road to adoption in the retail industry. Leading the way on this journey has often been large tier 1 retailers, either investing and experimenting with the technology in-house or partnering with early RFID specialists like Detego.

However, in the more settled retail RFID industry of today, implementing the technology is a different prospect. Here’s 4 reasons why there’s never been a better time for small and medium retailers to reap the benefits of RFID:

1) RFID has Lowered in Cost

Naturally, price point is a huge factor in choosing to implement a new technology for retailers of any size. Like most technologies, RFID was at its most expensive when it was new, but over time has become more and more affordable. This drop in cost is mostly down to the price of RFID tags themselves decreasing significantly. In the early 2000s, tags cost up to $0.75 (Approx. £0.50) whereas these days the average cost is between 3 to 8 cents (so around £0.05).

Developments in hardware and software also make a difference to the price point of RFID projects. For small and medium sized retailers, in particular, the need for only a single handheld reader per store, new hardware like mobile RFID label printers, and the availability of modular cloud-based SaaS solutions can lower the initial investment required to get started with the technology. This combination of industry progress makes leaner, more affordable RFID solutions a reality.

2) The Established RFID Industry Presents Less Risk and Better Knowledge Application

In the early days, RFID projects presented something of a risk. Bigger brands have the resources and personnel for (often in-house) ‘trial and error’ projects, but smaller organisations do not. Now that Retail RFID is an established sub-industry, retailers no longer have to go it alone and have far more options in terms of vendors, partners and solutions. This often means no steep learning curves and more stable and effective digital transformations. In other words, it’s now known what works and what doesn’t work for RFID in the retail industry.

How has RFID become more feasible for retailers over time?

- Expanded and established use cases

- Project stability

- Securing return of investment

- Easy and less expensive implementation

3) RFID Implementation has Become Easier

Historically, implementation has always been a barrier to entry for RFID. This is because adopting RFID is a fairly transformative project, meaning you have to make significant changes to see the significant benefits. Unfortunately, these changes have looked too daunting for many a retailer, especially for smaller brands who don’t have the resources to spare on long projects or clunky transformations. In recent years however, established RFID solutions offer more of a ‘plug and play’ experience.

How has RFID implementation changed for retailers?

- Out-of-the-box solutions

- Cloud-hosted platforms

- Smart shield

- Able to print and encode labels on-site

4) Scalable Solutions are the Perfect Platform for Smaller Retailers to Unlock the Value of RFID

As well as easier implementation, scalable SaaS solutions are now common practise, making RFID projects easier to manage and develop over time. A scalable solution means retailers don’t have to jump straight into the deep end. This makes the technology far more accessible for retailers of all sizes, but perhaps particularly for smaller sized retailer who have a limited technology budget and need to invest over time.

Scalable solutions, like the Detego platform, often focus on core deliverable KPI’s like inventory accuracy and product availability in stores. This is because they provide immediate ROI as well as being the key foundation for many of RFID’s other use cases. One of the main benefits of scalable RFID for smaller retailers is the quickly established ROI can fund the additional investment needed to scale the solution, providing a much easier route to full adoption.

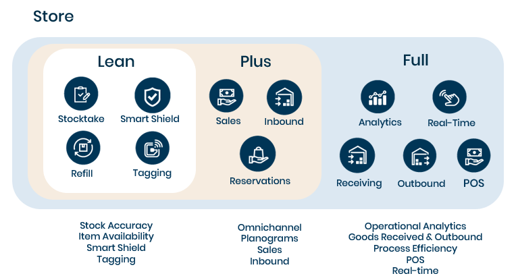

Here’s an example of what a scalable in-store RFID solution (The Detego Store platform) looks like:

Putting It All Together – What an RFID Project Should look Like for a Smaller Retailer.

So, a smaller retailer can take advantage of RFID with only a single handheld reader per store and a lean cloud-hosted RFID solution run through a mobile application. Other than the initial change in production to introduce source-tagging (adding RFID labels at the factory) implementation for such a solution is very minimal. The result of this would be rapid increase in stock accuracy, product availability and a subsequent increase in sales. This type of project provides an almost immediate return of investment, the retailer could then choose to scale and advance their solution at any point or stay with what they have and benefit from a leaner, better managed inventory.

Summary

Not only has the technology matured, including tags, hardware and software, but RFID use cases, best-practise and implantation strategies have now been firmly established. Additionally, the RFID sector is now an established market in its own right, meaning smaller enterprises don’t have to go it alone. By using established and experienced specialist partners, retailers can skip the learning curves and go straight to reaping the benefits of RFID.

Want the latest retail and retail tech insights directly to your inbox?

It’s that time of the year again where Santa Claus is faced with the busiest season of all.

While other retailers are looking forward to a few days of well-earned rest, Santa and his operational team are preparing for a night that would make the most seasoned logistics specialist cringe.

For years and years, children and supply chain operatives alike have wondered just how he does it…

A Tall Order

The original direct-to-consumer model, the North Pole operates the largest factory & distribution centre in the world. As well as the sheer quantity of items, they also deal with a razor-thin delivery-window that makes even Amazon Prime look simple.

Not only is there a head-spinning quantity of orders to contend with, but complete accuracy is a must. Unlike ASOS, a brand that also deals in great quantities; Santa doesn’t have a returns policy.

Instead, mishandled packages and incorrect deliveries break brand-trust and innocent hearts.

Well, this year the international-gift-deliverer has revealed the secret to their success in delivering world-wide miracles: The Detego Platform.

A Magical Solution

Responding to dramatic industry change including higher demand, fierce competition from e-commerce and children making requests through multiple channels, The North Pole decided to undergo a digital transformation.

The North Pole teamed up with Detego to give every single gift a digital identity. This allowed Santa and his elves to know exactly what they had in stock, ensure 100% accuracy in shipping and to track individual items in transit around the world.

Since every item is produced on-site, The North Pole can easily source-tag every present with RFID.

Santa’s elves then do full cycle counts of their inventory to make sure they’re fully prepared for Christmas. In previous years, this started in September and ended in November! Now, with the multi-user Detego application, lots of elves can take a stock read at the same time without the need for direct line of sight (cutting the ladder budget in half), and leaving no room for error.

No Need to Check the List Twice – Accurate Data You Can Trust

From this accurate view of inventory Santa and his team then sort and distribute presents, using RFID enabled pick-and-pack and exception handling. With modern RFID processes, this ensures no mistakes take place, so no children accidentally receive coal even though they’ve been good that year.

Crucially, by using automated RFID tunnels The North Pole can check every item is correctly packaged and accounted for without ever needing to unwrap presents to double check!

With a system as sophisticated as this, Santa can simply sit back, relax and enjoy Christmas knowing everything’s taken care of.

– From everyone at Detego, we hope you enjoy yours too.

Merry Christmas and Happy Holidays!

‘Christmas presents are magical things, so we needed an equally magic solution to make sure they get to the right place on time, we’ve always worked very hard to do this, but now it’s easier than ever!’

– Santa Claus

(For an introduction to combining AI and RFID see this article)

When it comes to using Artificial intelligence (AI) and Radio Frequency Identification (RFID) in retail for process optimisation, the majority of use cases involve management or ‘HQ’ level decision making. These include automating functions such as store planograms and stock optimisation between stores.

However, AI can also impact retail on a much more micro and everyday level, actively assisting store staff in one of their most common daily routines –stock replenishment.

Using RFID and the information it collects from stock reads, we can produce AI pick lists to optimise and guide staff through the replenishment process. Not only are we combining RFID technology and AI algorithms to produce these pick lists, but existing RFID processes are already assisting staff. When you put all this together, replenishment become a walk in the park.

Let’s start at the beginning…

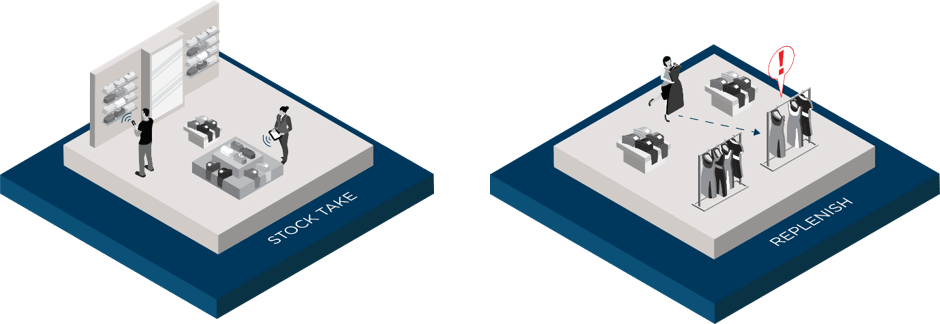

RFID-based Stocktake and Replenishment – The backbone of modern stock management

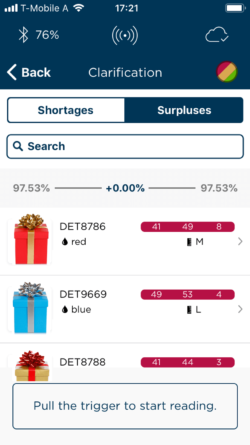

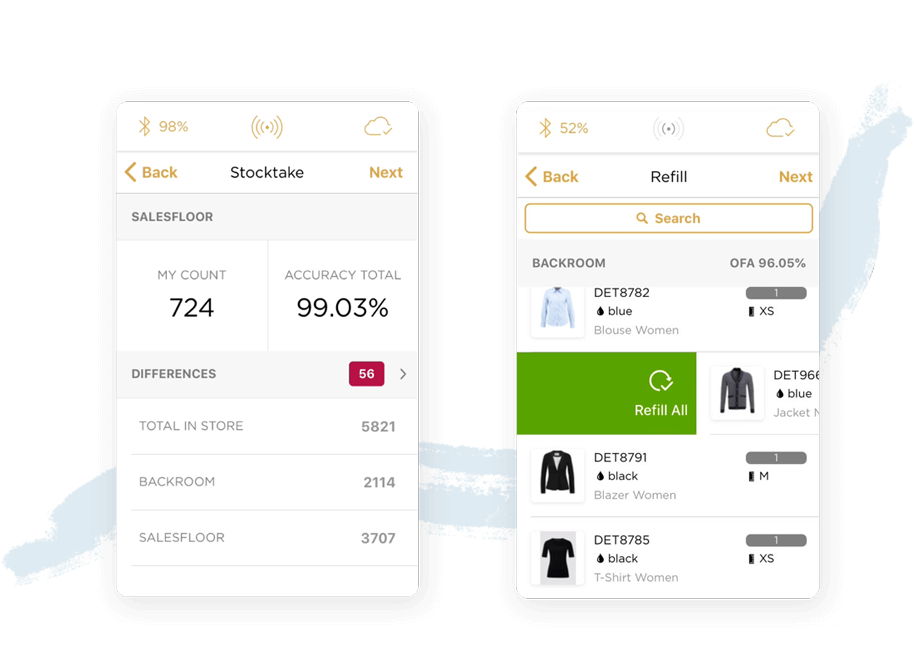

With RFID, store staff can do regular (often daily) cycle counts of the entire store quickly and easily. This is simply done by walking around the backroom and salesfloor with a handheld reader that counts items that are several feet away, using radio frequency. An RFID application or software, like the Detego platform, will then compare the actual stock levels of the shop floor with the desired counts (i.e., planogram), and tell staff exactly what needs to be replenished from the backroom.

So far, what has just been described has been entirely RFID-based and is the standard process for RFID in retail. This is already far easier and more accurate than traditional methods, not to mention the actual effect of the technology like higher stock accuracy and product availability. But why stop there?

Taking it one step further – AI pick lists for ‘mapping’ the perfect replenishment path

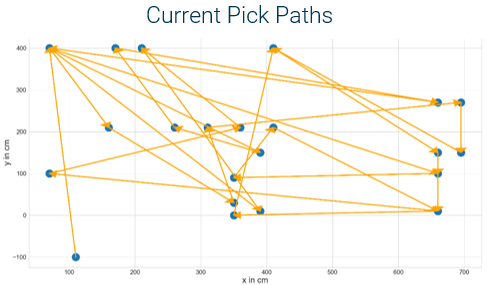

Normally, even with the support of RFID, the store staff are then left to fulfil replenishment by themselves, using the list provided by the application. These pick lists are often only sorted by product features such as name or price. Because back rooms can be quite large in bigger stores, or densely packed in smaller ones, the staff’s ‘pick path’ can be incredibly sporadic. This is made even worse in the case of new staff who don’t know the layout of the backroom by heart, or even experienced staff if stock has simply been moved around and updated with the start of a new season.

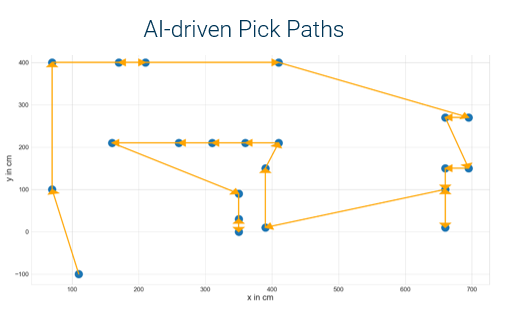

By utilising new tag localisation techniques, it is now possible to locate where items are in the backroom in relation to each other. This is done during the regular RFID stocktakes that are already taking place, utilising data mining and machine learning pipelines without any need for additional hardware or specialist tags. Using this information, we can create automated AI pick-paths that, using a mobile application, guide staff through replenishment and present the most efficient order to collect items in.

The above example is designed to present the quickest possible replenishment route for staff, so is solely using items’ distance from one another to calculate a pick list. However, AI pick lists can process the replenishment list in a number of ways, depending on what the store wants to focus on.

Replenishment paths could take additional factors such as product value or expiry date into account, alongside the location of the items. It would then look for items that fit this rule and are nearby one another in the backroom. For example, a pick list targeting on-floor-availability would group nearby items that are running low on the sales floor, so that these items are refilled first to speed up the replenishment process whilst also combatting loss of sales from out of stocks.