Shrinkage has always been a critical challenge for retailers, but now post-pandemic, there is much more than inventory at stake.

Why Retailers Must Invest in Loss Prevention

Managing inventory levels is more vital now than ever before.

At the same time that out-of-season stagnant stock sits untouched in warehouses, desirable inventory is increasingly becoming short in supply on shopfloors. In fact, when slow-moving stock can still make up to 40% of a retailers inventory, it seems strange that the current shortage of goods is reportedly here to stay. But taking this juxtaposition into account, it’s not hard to predict that many more retailers will be feeling the strain of simultaneously being overstocked and out-of-stocked as the holiday season approaches.

At a time when struggling businesses could stand to increase revenue drastically, they will have to be more strategically minded, optimising the distribution of limited inventory and harnessing emerging opportunities to turn obsolete stock into profit. In order to do this, however, retailers will need to actively seek to improve their loss prevention processes as every item of stock – even obsolete inventory – becomes increasingly more vital to lifting the bottom line.

The Impact of Inventory Loss in the Post-Pandemic Environment

Due to the heightening imbalance of desirable and undesirable stock, it is no exaggeration to say that within the grand scheme of a retailer’s operation, even a single piece of inventory can drastically impact a business’s opportunity to make money or lose it.

For instance, with the circular economy booming, the slow-moving stock is increasingly being repurposed to recuperate costs, while inaccurate real-time product availability of popular goods could negatively hinder a retailer’s ability to build omnichannel relationships with customers.

That is why shrinkage – when a business loses inventory for reasons other than sales – is a driving issue for retailers and one that looks to exasperate the inventory challenges already at play.

Last year, shrinkage cost the US retail market $61.7 billion, and as supply chain disruptions continue, retailers will increasingly need to tighten their control over assets at an item-level scope, especially now that their distribution strategies are influenced by localised demand for particular product categories, styles, and sizes as customers continue to expect personalised and immediate services.

But to facilitate this level of customer service, improvements to inventory management must be made that prioritises precise inventory tracking and agile loss prevention.

Causes of Shrinkage are Becoming Increasingly Complex

To improve their loss prevention strategies, retailers must get to the root of the current shrinkage causes that are growing more wicked in nature due to inventory touch-points multiplying at speed. Here we explore the most coming reasons for stock loss in retail and why they are challenging businesses today:

- Returns Fraud

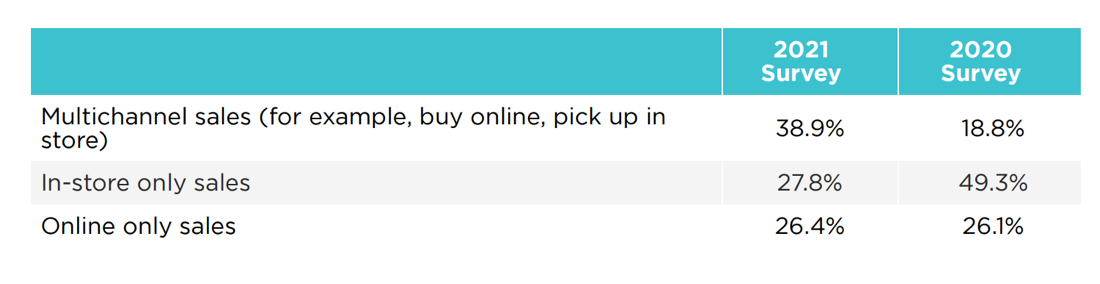

Social media has contentiously given rise to the trend that it’s “unfashionable” to be photographed in the same outfit twice, leading to a growing community of serial returners who consistently purchase fashion products, wear them once or twice and then return them. And as social commerce grows –generating more and more omnichannel touchpoints – so do the opportunities for fraudulent returns within this growing trend. Last year, scams involving the returns of products already cost retailers $43 billion, and in this year’s National Retail Security Survey 2021, retail companies reported that multichannel sales had created the most significant increase in fraud this year.

As customers continue to purchase online and then pick up orders in-store and vice-versa, the challenge for retailers is that they must cater to the growing demographic of digitally literate consumers who now move between online and physical touchpoints whilst implementing inventory traceability. Because if not adequately managed, omnichannel can open up opportunities for stock loss, with fraudsters taking advantage of any discontinuity between online and offline returns processes.

2. Shoplifting

Even with mandated closures for much of the year, 2020 saw UK retailers lose over £770 million from shoplifting alone. So now, with physical stores firmly back open, shoplifting has re-emerged as a critical challenge of retailers who are hoping to turn these spaces from loss-leaders to optimal environments for customer engagement.

Criminal activity in stores, however, not only poses a threat to the bottom lines of these operations but can also negatively impact the experiences of customers and employees. Especially now that many companies have begun to take a stronger social stance towards the wellness of their workforces. Retailers must from now on empower employees to handle shoplifting efficiently, confidently, and safely.

3. Employee Theft

Global employee theft is predicted to cost retailers 2.9 trillion annually and accounts for 28% of inventory loss, with physical goods most likely to be stolen from the workplace. Viewed as an epidemic within the retail ecosystem, there are many diverse existing approaches to loss prevention, from behavioural focused strategies such as staff recruitment and training processes to physical deterrents such as CCTV and POS data mining.

Product visibility is non-negotiable for retailers embracing omnichannel

The challenge for retailers who are tackling employee theft, however, is in how to build a connected and holistic solution that improves workforce attitudes and culture towards stealing, reduces opportunities for theft and at the same time incentivises them to become active players in inventory protection.

- Damages

It goes without saying that damages to inventory are inevitable. As goods that are often journeying to far-reaching locations, wear and tear in transit is to be expected and – although not ideal – retailers commonly anticipate this reality and reflect it within their financial accounting. At a time, however, where in-demand stock is in short supply, damages to assets is being viewed as a growing nuisance that, whilst wholly unavoidable, should be dramatically reduced.

But it is the reporting of damaged goods that should be a significant concern for businesses. Again, as consumer sentiments move towards fast fulfilment, retailers will need to have precise real-time insight into stock availability, and its location, yet unaccounted for damaged items can sabotage a business’s ability to carry out effective customer services.

- Administrative and Supplier Error or Fraud

Error or fraud in the reporting of inventory levels is a severe problem that multiple stakeholders can enact at any given time. It is vital to a retailer’s bottom-line that delivery of goods from vendors is 100% correct at the time of receipt. Whether intentional or not, incorrect data from suppliers could have knock-on effects throughout the supply chain down to stocktake on a shop-floor and incorrect e-commerce order fulfilment.

At the same time, what could seem like minor mistakes such as pricing or labelling errors can snowball into significantly lost profit, lapses in customer satisfaction, and employee frustration. And in fact, administrative and paperwork errors can account for 18.8% of annual shrinkage. In order to mitigate these errors, retailers must begin to explore how inventory data can be communicated correctly and consistently throughout these various internal touchpoints

Why Current Methods of Loss Prevention can Lack Long-Lasting Results

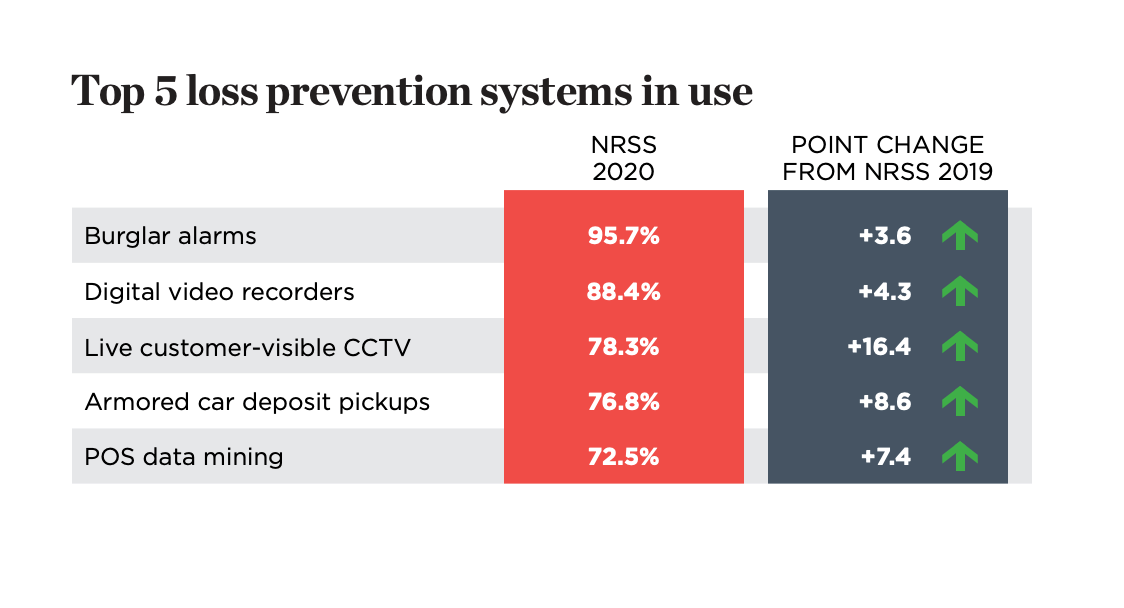

Loss prevention has to date, been an issue of high importance for the retail sector. Still, the recent acceleration of technology adoption has provided a window into the efficiency that digital-driven supply chain management presents. While current loss prevention methods are year-on-year, reducing the cost of lost goods, these solutions can often lack depth and breadth as they operate in silos from one another.

Additionally, many of these existing strategies, such as alarms and armoured cars – while effective – predominantly focus on mitigating the loss of large quantities of stock rather than at the item-level that is becoming increasingly important. At the same time, they often do not account for reducing back-end administrative fraud and errors such as incorrect delivery dockets.

It is, therefore, critical that continuity of information is built into future loss prevention strategies so that goods are traced throughout the entire supply chain, and long-term improvements can be implemented.

How RFID Can Prevent Shrinkage in One Simple Solution

Smart-Shelving

RFID’s ability to help retailers monitor how customers interact with their products to improve personalisation and recommendation in stores can subsequently work in favour of loss prevention. For example, RFID enabled smart shelving sends a trigger to employees whenever stock is low and can help report real-time anomalies of inventory movement and location tracking.

The technology’s ability to send stock quantities and location information to multiple stakeholders in stores, head-office and warehouses could act as a significant dissuade employees hoping to isolate incidents of theft. Additionally, the simple existence of an item-level RFID tag can act as an effective deterrent to shoplifters.

Returns Processing

Due to RFID being able to trace inventory throughout the entire supply chain, this software can act as a journal for any product, providing evidence of where it has been before being returned into a retailer’s ecosystem. In turn, this can allow businesses to identify where returns fraud is happening and assess where the weaknesses are in their returns process.

Data collected can also provide insight into the kinds of products experiencing serial returns and investigate if this is down to poor quality, fit, or even if the item is highly “Instagramable” rather than wearable. These are all essential datasets that can be fed back to designers, marketers and manufacturers who can, in turn, look to reduce the reason for returns within their roles.

Automated Real-Time Updates

The automated updates that RFID provides allow companies to manage inventory with more connectivity within their operations. Unfortunately, inconsistent communication between the complex and isolated processes within retail operations has for a long time provided the opportunity for administrative, human errors and fraud.

RFID simplifies communication and allows warehouses, distribution centres, and stores to correlate physical stock against digital information at the item level. Additionally, RFID removes chances for vendors and employees to tamper with data and falsify information.

RFID Can Makes Data-Driven Loss Prevention a Reality

Not only can RFID act as a deterrent, but it can also help businesses to build resilient future strategies that reduce the causes of inventory loss at the source.

As an offshoot of the all-important supply chain transparency we discussed last month and item-level visibility the retail sector still struggles to enforce, RFID’s ability to deliver data-driven insights and pinpoint precisely where inventory loss occurs is highly valuable for highlighting areas for improvement within the supply chain and possibly uncovering reasons for the unattributed loss.

Book a demo with Detego today to see how our inventory transparency software can help you tackle loss prevention challenges.

Cloud-hosted RFID software

Stock accuracy, on-floor availability, and omnichannel applications in stores.

Detego Store is a cloud-hosted RFID solution which digitises stock management processes, making them more efficient and more accurate. Implemented within hours, our multi-user app can provide intelligent stock takes and a smart in-store replenishment process. Later, you can scale the solution to offer omnichannel services and effectively manage your entire store operations with real-time, item-level inventory visibility and analytics.