Supply chain disruptions are not likely to disappear anytime soon. So can retail investment into supply chain management help businesses to face current and future challenges head-on?

Can Retailers Recover from the Supply Chain Crisis?

Until recently, it has been relatively easy for consumers to take the smooth supply chains that serve them for granted.

But the pandemic’s continued impact on retail — generating tidal waves of disruptions — has demonstrated just how reliant contemporary customers are on frictionless and immediate delivery of goods.

In just the past three months, the retail sector has suffered the effects of everything from food shortages, factory fires, to torrential weather. All of which have pushed supply chains to breaking point and — for many experts — have been the worst disruptions they have ever witnessed.

Every day, there are news reports of global brands running out of stock, failing to open stores and delaying the delivery of products, subsequently impairing their ability to provide the immediate gratification customers have come to expect from their shopping experiences.

So as the start of the next financial year swiftly approaches, retailers have begun to set their sights on investment in supply chain solutions to navigate future problems — and for a good reason — these challenges have created speed bumps in economic recovery, and according to ING, supply chain issues are here to stay.

However, if retailers have learned anything from the past 18 months, it is that these problems are not in silos of specific geographical locations, sectors, or product categories. Instead, they are an interconnected global web of causes and effects that — at the start of 2020 — retail had primarily been unprepared for. But the industry now knows that to survive, they must embed these lessons into their operations, strategically and efficiently.

Future Supply Chains: From Outdated Systems to Innovative Digital Solutions

Research from 2018 found that visibility, fluctuating consumer demand, and inventory management were already some of the most concerning global supply chain issues.

So it comes as no surprise that the pandemic has not only exasperated these sizable problems, but it has exposed global supply chain operations as outdated processes that often create rather than remove points of immense friction.

But now, moving into a post-pandemic era, revisiting and adapting the legacy processes many supply chains operate upon will not be enough for retail’s survival. Instead, businesses within the sector must begin to consider the solutions confronting supply chain challenges in new and innovative ways designed to work in the world retailers are currently navigating.

Digitisation is central to how these kinds of solutions function, yet before Covid-19, only 15% of US retail businesses had entirely digitised their supply chain management processes, despite 60% of US retailers viewing supply chain digitisation as crucial. However, the acceleration of technology over the past 18 months has presented many opportunities for businesses to integrate these agile and efficient digital systems.

And as a result of the large number of technologies aiming to revolutionise the industry, the supply chain management market is estimated to reach USD 30.91 Billion by 2026.

Current Supply Chain Disruptions and their Emerging Solutions

Today, with supply chain disruptions varying in scope and scale, it is essential that before investments are made, retailers attempt to understand the impact of each problem at every stage of a product’s life cycle to decide upon the best solutions to invest in.

Here we explore the most significant supply chain challenges that retailers are currently and will continue to face alongside the innovative solutions helping to resolve them:

Unpredictable Customer Demands In an article just last month, we looked into the post-pandemic consumer and their unpredictable and ever-changing demands. Whilst uncertainty may be subsiding as the retail sector slowly recovers, consumer experts are still unsure of the long-term impact of the pandemic on customer sentiments. Yet, with retail supply chains hinging upon the fulfilment of customer needs, this uncertainty could cripple a businesses revenue.

AI Forecasting: As AI-driven forecasting begins to mature, many businesses in the retail sector are finding themselves reliant on data-driven foresight to prepare for uncertain customer desires and mitigate the risk of history — as recent as early 2020 — repeating itself.

Shipping Delays

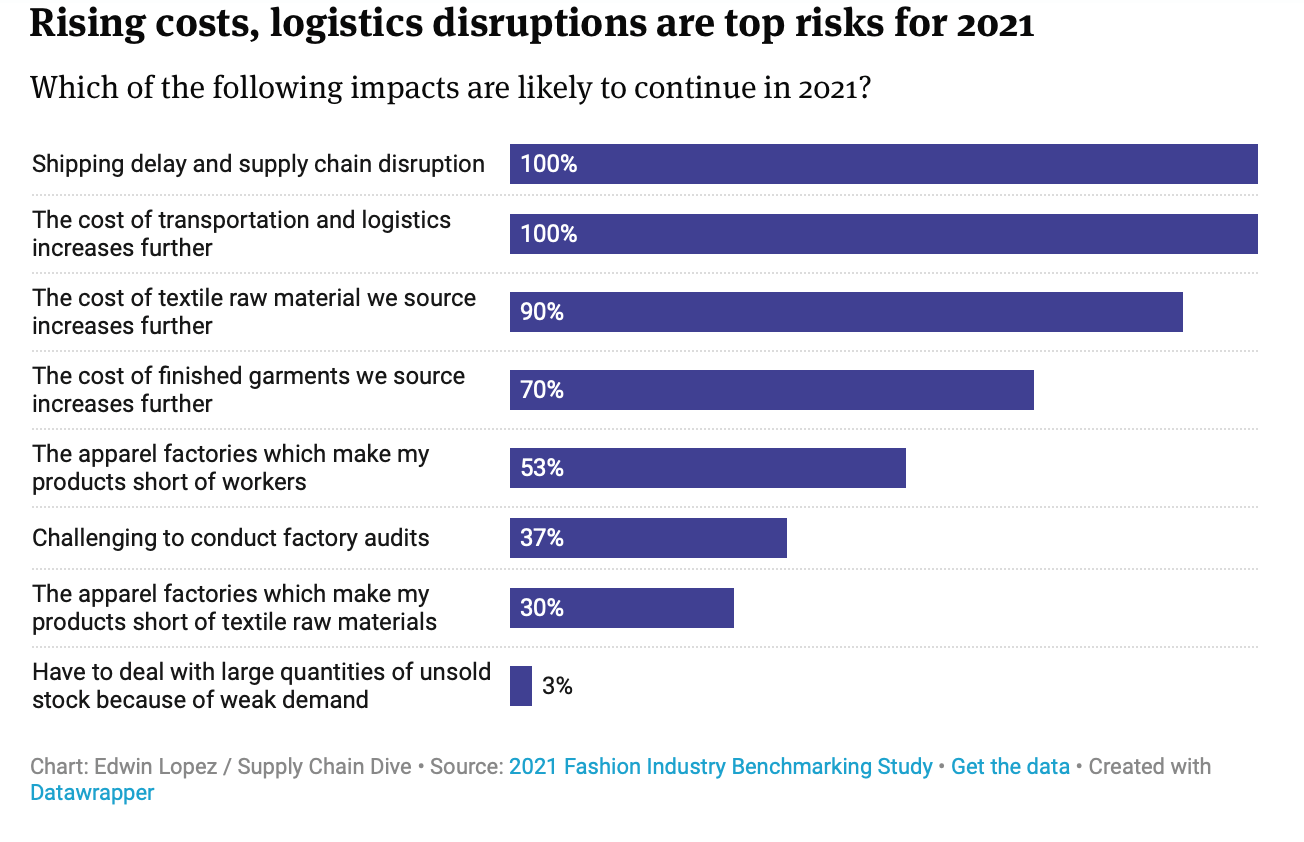

The blockage of a container ship in the Suez Canal in March this year, causing widespread delays worth an estimated $9.6bn of lost trade each day, illustrates how reliant supply chains are on tried and tested operations. Still today, air, sea and land distribution continue to struggle under the weight of these overwhelming market dictations, with retailers running the risk of paying for the storage of products with subsiding customer demand.

Lean Inventory: With no quick fix to shipping backlogs, an increasing number of retailers are broadening where they source their stock from and readdressing how they distribute their goods by exploring lean inventory processes. In this supply chain management method, companies attempt to reduce the waste they generate by lowering the volume of inventory and moving fulfilment closer to demand, ultimately scaling down their shipping needs and shortening lead times from factory to store. Overall, this strategy allows retailers to quickly respond to fluctuations in delivery times, recalibrate their logistics, and reduce the risk of money lost upfront.

Disjointed Workflows

As the nature of employed work becomes increasingly decentralised from offices, retail operations have had to quickly adapt their workflow processes to transfer information and efficiently facilitate teamwork throughout the supply chain. And technology has been a vital foundation for this shift towards the remote yet more connected working styles that have helped entire economies stay afloat over the past year and a half.

Cloud Software: In a recent survey, 83% of business executives say that their businesses now prioritise building and maintaining relationships with existing suppliers, and Cloud software has become integral to the management of these relationships. According to Accenture, “The cloud provides technologies that allow companies to process huge amounts of data—from virtually unlimited sources across the entire supply chain—at speeds and volumes never before possible.”

In practice, more immediate and precise communication between retailers and suppliers can speed up arduous back-and-forth processes such as quality control. Alongside this, the agile nature of the technology allows businesses to create digital continuity throughout entire product life cycles to make agile real-time decisions about goods at every stage.

Labour Shortages

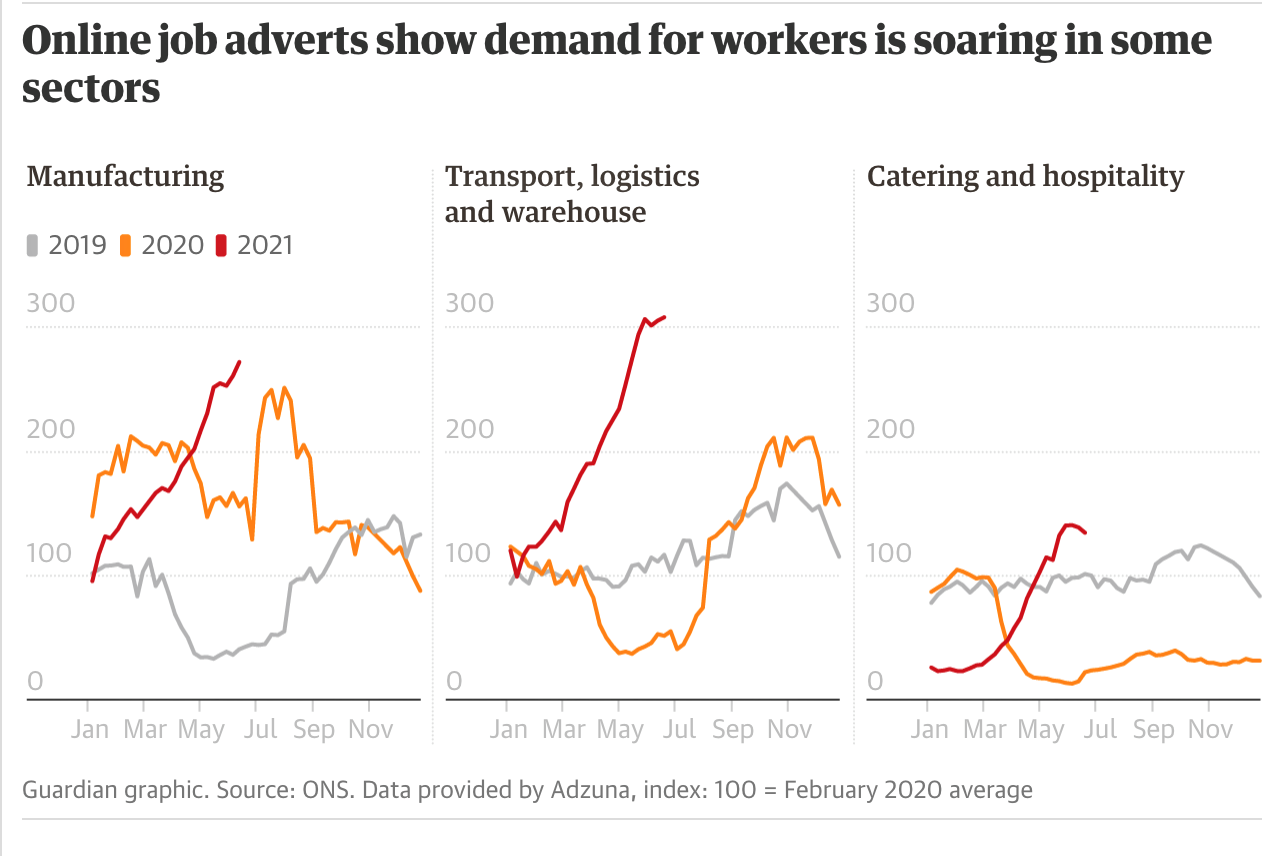

The impact of furloughs, redundancies, and under-employment catalysed by the pandemic can still be felt today, as job vacancies continue to rise sharply — particularly in manufacturing and logistics. These workforce gaps have been detrimental to retail recovery, causing insufficiently staffed stores to shutter their doors and order fulfilment schedules to be derailed due to limited warehouse teams. However, these ongoing labour shortages have left retailers scratching their heads — and experts Unhappiness, skills gaps, and at home commitments are all cited as viable explanations.

Employee-First Technology: Providing existing employees — and enticing new staff members — with digital tools that increase job satisfaction and upskill talent is crucial to building back workforce numbers. For example, RFID enabled inventory management software helps employees enhance capabilities to fulfil customer orders whilst reducing the time spent on labour-intensive stock takes and subsequently optimising the daily tasks staff.

Micro-Warehouses: To solve this problem more immediately, micro-warehousing is becoming a popular solution for several reasons. This setup allows retailers to break down their distribution hubs into smaller and easier to operate locations such as brick and mortar stores. Thus, generating opportunities to recruit from more localised communities and creating more manageable workloads whilst providing opportunities to utilise their recently loss-leading physical presence.

Lack of Transparency

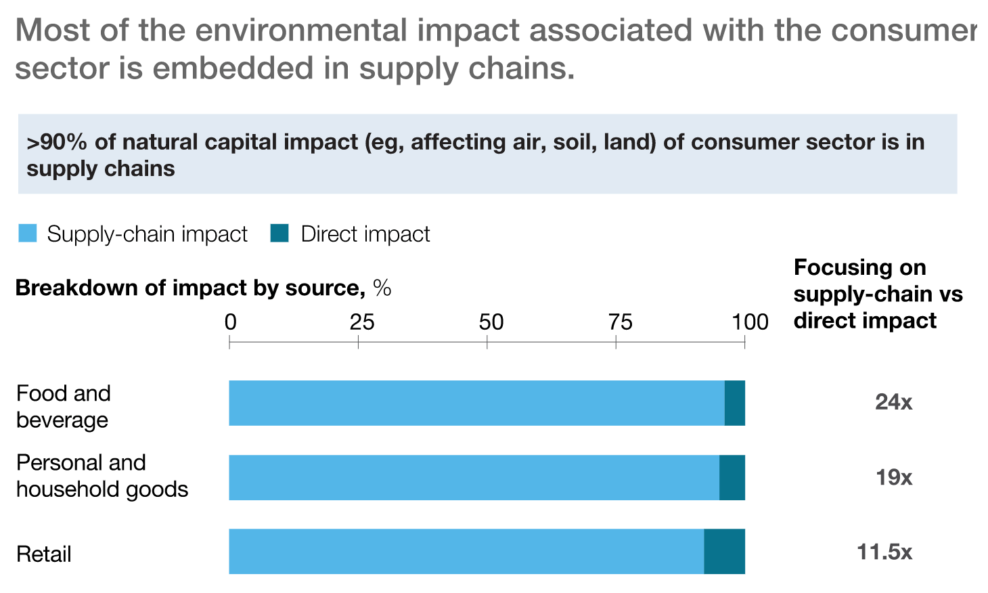

Just this month, global fast-fashion retailer and market leader Shein have been accused of ethical violations in the manufacturing and sourcing of their products due to limited transparency within their supply chain. Supply chain transparency has become a growing concern for empowered consumers in recent years as they more readily use their wallets to support businesses whose actions align with their own values. Meanwhile, for retailers, supply chain clarity will help them better to understand every stage and better control their operational costs.

Compliance Technology: Compliance solutions supported by blockchain technology are increasingly helping retailers make opaque internal processes more transparent and prove their commitment to marketed moral values by securely tracking and immediately mapping the regulatory compliance of their manufacturers.

Environmentally Damaging Footprints

According to McKinsey & Company, the typical consumer company’s supply chain creates far greater social and environmental costs than its own operations. This is worrying for both direct and indirect stakeholders such as customers, investors, governments, and activists. And due to the globalisation of retail — as products move back and forth from factories to warehouses to customers across continents — this problem is only growing.

Carbon Footprint Tracking: Recently, carbon footprint tracking has seen a recent uptick in interest due to its ability to quantify the environmental impact of everything from an aeroplane ride to a laundry wash. Therefore, software that calculates CO2 is an interesting solution for helping retailers to understand both the holistic impact of their supply chain whilst at the same time breaking it down to item-level data so they can pinpoint problem areas and make more granular decisions.

Supply Chain Digitisation is Vital, but Where to Start?

At first glance, solutions that reduce risk and enhance responsive decision making are obvious front-runners for retail investment, but considering in context the tangled disruptions retailers are facing, it is the technology that is critical to supply chain innovation.

However, with the vast number of problems retailers face, business leaders must also strategise on how to begin implementing these supply chain solutions and prioritise which problems to approach first. Moreover, due to the complexity of their supply chains, retailers will need to find multifunctional Softwares that are quick to implement and deliver fast results — especially since, in retail, agility was a winning characteristic of market leaders throughout the pandemic.

Here we discuss the three key features retailers should be prioritising when investing in digital supply chain management solutions:

- Multi-Tasking

With supply chain disruptions as deep-rooted and complex as they currently are, management tools that solve multiple problems at once are highly valuable options for retailers of any size. For example, fashion brands New Look, H&M, and Next have just begun piloting an IBM supply chain platform that combines several different technologies such as AI and blockchain to increase transparency and allow the various stages of supply chains to connect and communicate with one another.

- Speed

The continuous volatility and unpredictability of the global landscape makes it vital that supply chain solutions deliver almost immediate results to work alongside the often fleeting context of the market on any given week, day, or even hour. Take inventory software Detego, for example, which uses RFID to provide quick results that are responsive to immediate changes throughout entire operations helping businesses to view inventory levels in real-time and distribute stock globally and locally.

- Ease

In another article earlier this month, we touched upon the importance of employee adoption of technology and discussed the importance of user experiences that help to embed digital solutions into the everyday roles of workforces. It is key that solutions are easy to adopt for a variety of employees at every level. For instance — as previously mentioned — Cloud technology like Oracle helps retailers to generate digital continuity within their workflows by seamlessly transferring data between various stakeholders throughout operations.

The benefit of solutions that tackle multiple challenges with speed and ease is that they are less likely to become obsolete as their capabilities evolve alongside the post-pandemic market and efficiently reduces the number of supply chain evaluations needed every quarter.

Why it’s Important to Investing in Supply Chain Technology Now

As consumer demand for goods continues to move away from predictable seasonal patterns and towards erratic, unpredictable surges, and their loyalty falters, expectations for immediate fulfilment, unparalleled services, and complete transparency are meteorically rising. Meaning a retailers success will depend upon competing to cater to these demands effectively, and honing a frictionless supply chain is vital to achieving this.

So for both retailers on the brink of survival and market leaders, using the upcoming financial year to invest in supply chain management solutions and optimise operational costs is essential.

Yet, luckily for the retail sector, digital supply chain solutions are both growing in diversity and maturing in ability — and it is wise not to take this point in time for granted. Because looking forward, it is clear that rather than waiting for supply chains to snap back to their pre-pandemic states, businesses that accept their volatile new normal and build strategies for the reality of a post-pandemic era will surely be positioning themselves to take disruptions in their stride and stand out in the struggling retail market.

Cloud-hosted RFID software

Stock accuracy, on-floor availability, and omnichannel applications in stores.

Book a demo with Detego to find out how RFID inventory management can help your business to tackle multiple supply chain disruptions at once with fast results and easy implementation