Detego and Zebra Technologies have a long-standing partnership with successful global RFID rollouts. Joint customers include some of the world’s leading fashion brands.

Learn more in our new whitepaper about how this partnership approach provides the best and most sustainable approach to RFID implementation.

“By using Detego and Zebra RFID solutions to digitize stock counts one major global retailer increased inventory accuracy to 99%”

Complete the form below to download the case study.

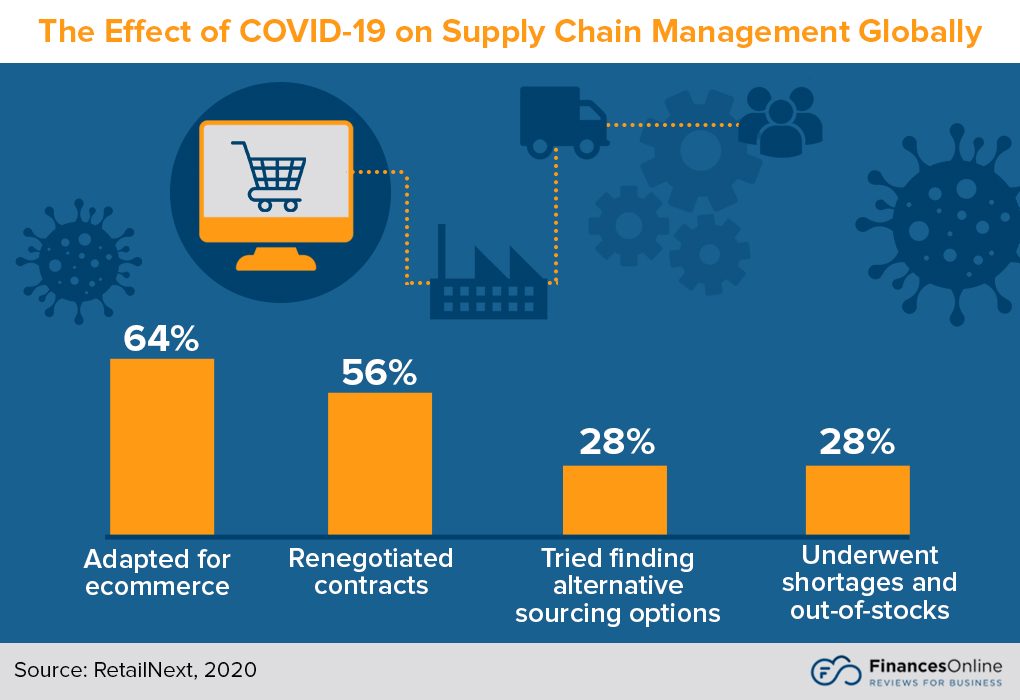

The size and complexity of global supply chains, with their significant resources and risk-mitigation strategies among multiple partners, were previously thought to create significant security. The ongoing COVID-19 pandemic continues to show how wrong that assumption was. Global supply chains are vulnerable and will remain that way without significant planning. Retailers are still vulnerable to large-scale threats as well as regional issues like labour shortages and lockdowns.

For retailers looking to plan and protect their supply chains, it’s time to prioritize risk mitigation and thorough reviews. This article will look at five areas where planning and understanding must be improved for them to adapt to the realization that significant risk is lurking in its supply chain.

Enhance workforce planning

Supply chains are heavily dominated by human labor. People are present at multiple points for every single supply chain action. What COVID should remind supply chains is that every worker needs protection and training. But labor also involves many potential risks. You’ll need to work to keep people safe and understand and plan for times when people are out sick, whether individually or as a group.

Companies should have a plan for increased absenteeism and labor shortages. The post-COVID supply chain will still deal with COVID, the flu, and other seasonal health threats. No one is quite sure what that’ll look like, but experts across a wide range of industries say we should continue to expect increased health screenings and safety protocols.

This means you’re at greater risk of being impacted by regional outbreaks or clusters of illness. Look for robust tools that can help you tackle these concerns on multiple levels. RFID, for example, has applications that can improve your inventory accuracy and on-floor availability while reducing touchpoints and allowing staff and customers maintain proper distancing. Reducing manual tasks, such as inventory cycle counts, also helps protect you against risks related to labor shortages. RFID can even create upsell opportunities as it reinforces health best practices.

Build a plan to address productivity and support losses related to illness-absenteeism. At the same time, continually train teams on safety and health protocols, enhance your cleaning regimens, and turn COVID spacing requirements (and others relevant to your facilities) into more permanent policies.

Start with alternatives at the last mile

One of the biggest pushes companies see in this shifting landscape is the desire to diversify their supply chain. That’s simple to say, but one of the most complex undertakings you can do during a time of uncertainty. Sourcing new manufacturers and establishing relationships in other countries for changing ocean lines or shipping routes are complex. The existing backlog means any shift will take time to test, verify, and approve.

Companies can make a more immediate shift in their last-mile delivery, the final leg of a shipment from your warehouse or facility to the customer’s door. Increasing carrier access by moving to larger facilities and establishing relationships with regional carriers alongside national partners can help any brand build up resilience.

In many cases, this need is a strong enough reason to look at outsourcing fulfillment at any stage in a business’s development. Third-party logistics providers (3PLs) have many of these relationships already. Their higher volume also enables the 3PL to negotiate strong rates and deeper discounts, which they should pass onto customers. 3PLs like Red Stag Fulfillment, which specializes in specific product categories or attributes, can help niche and dedicated businesses make the most gains by pursuing the most relevant carrier discounts or those targeting product types.

Trace from end to end

The COVID-era supply chain struggled, often because of shifting supply and production capabilities, while demand largely grew. Manufacturing shutdowns, port delays, and other breaks in the chain had compounding effects. It was hard to understand how to adapt to any single element, let alone these larger issues.

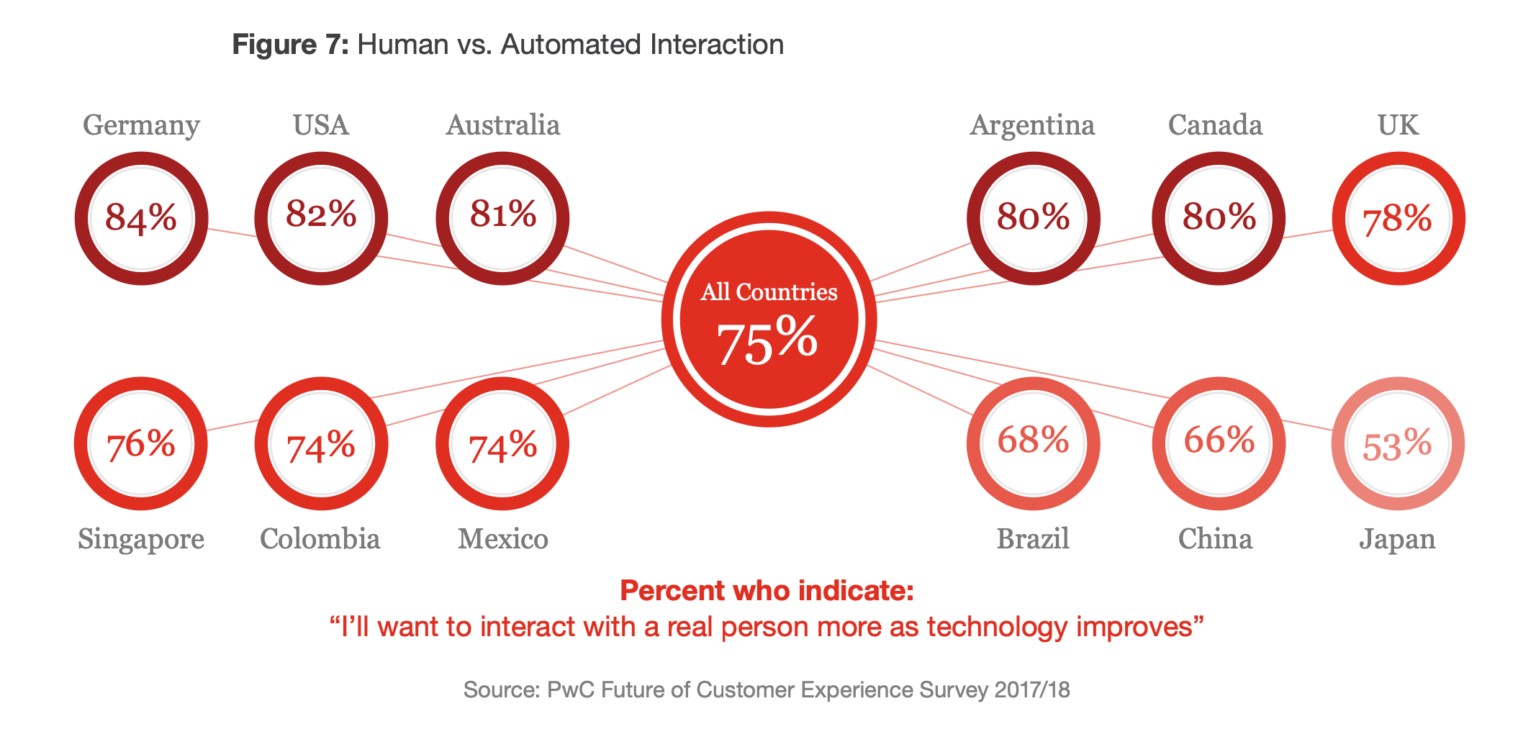

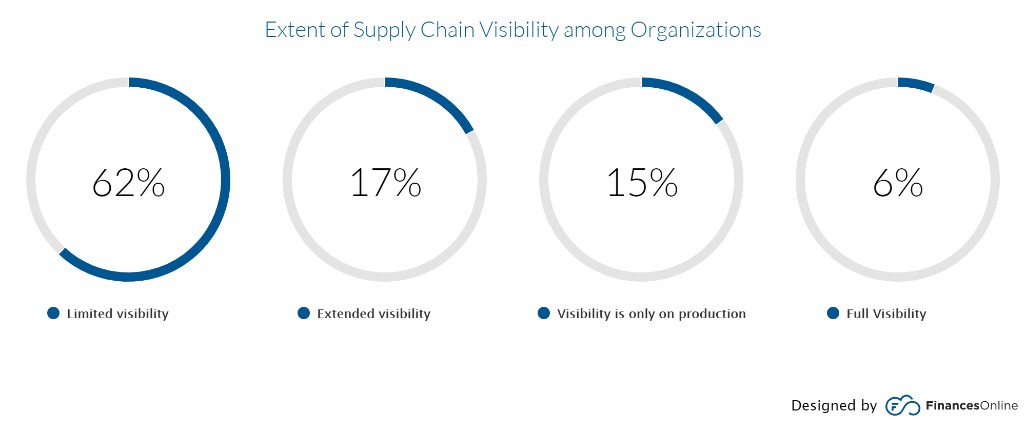

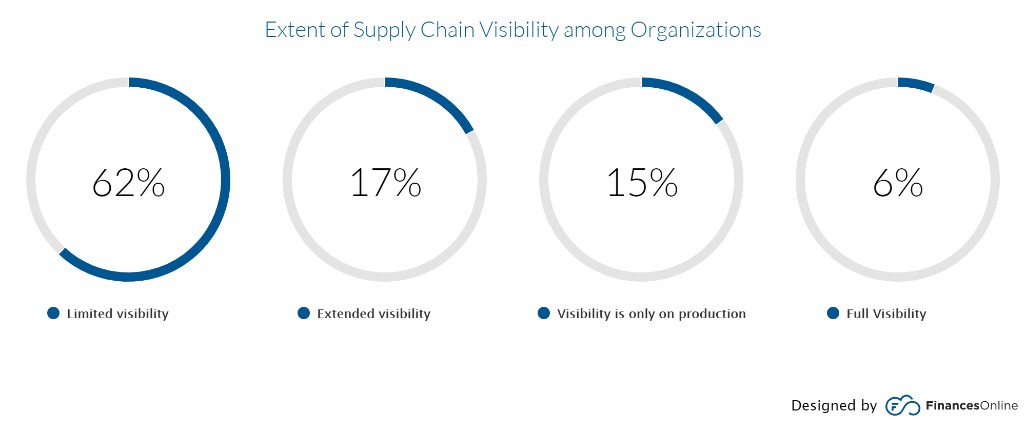

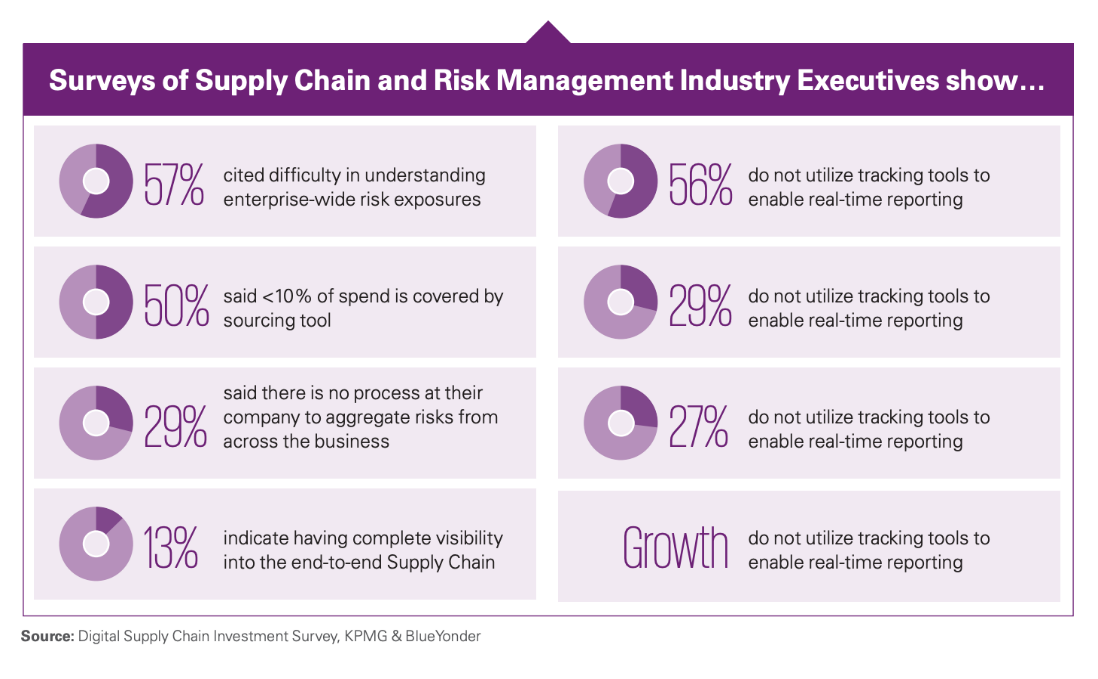

Subsequent reviews of supply chains and risk mitigation studies have shown that, while many companies have expressed interest in chain visibility, most struggle to implement this. That cannot be the case for a viable post-COVID supply chain. It’s time for eCommerce sellers, manufacturers, wholesalers, carriers, and intermediaries to share data proactively. You can start this conversation by reaching out to learn what technologies your partners use and find areas of common ground or shareable data and file types. Tackle it from multiple perspectives including your customers, 80% of whom want to know real-time availability.

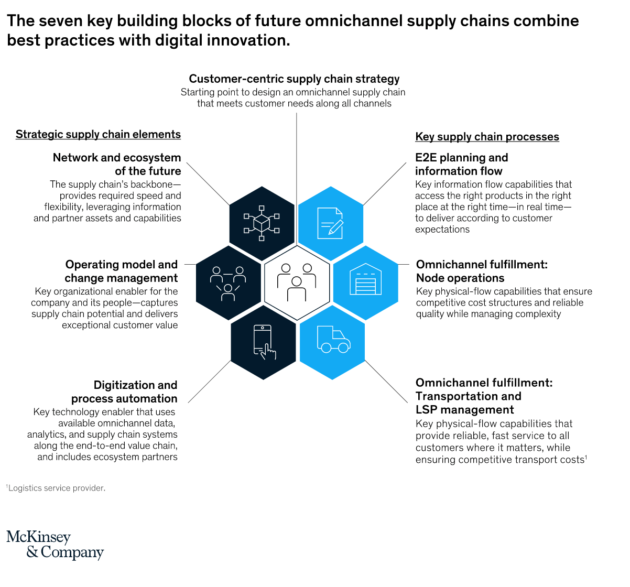

Thanks to current digital technology, end-to-end visibility is achievable, and we now clearly see its value. Align your investments toward information gathering and sharing to optimize other capital expenditures. Pursuing AI and analytics, 3D printing or additive manufacturing, improved conveyors, and other infrastructure technology first could create budget gaps that prevent the adoption of systems and communication strategies where you learn what’s happening at the manufacturing level and can understand its impact through the last mile.

Create an information-sharing plan if you want to be a preferred partner. Start the process by automating the delivery and sharing forecasts. When you detect a change or trend, share this up the chain to help partners better predict demand and strain, enabling them to allocate appropriate space when available.

Review inventory and available space

Supply chains are moving away from just-in-time inventory practices but there are struggles with what comes next. Instead of trying to define a completely new approach, look for adjustments you can make to take realistic steps for safety. For an inventory, that means balancing what you have in stock and preventing stockouts while not hoarding in a way that harms profitability or tying up too much capital. This requires you to get demand forecasts right.

Protect yourself by looking for periods of stockouts and pulling them from your demand forecasts. Run your analytics to plan based on demand when you were able to complete orders so that you’re not using low numbers. You might be able to double-check this work by looking at site traffic to sales pages — if it stayed consistent even when items were on backorder, then potential demand was steady.

After you’ve got forecasts that are correct for stockouts, look at the physical space you have available. How much can you fill? If you order more inventory than normal, do you have room for it? Balance that by determining how many additional costs you’ll incur for this holding. Higher inventory levels have higher labour costs, heating or cooling your facilities can change, you might use more equipment, and so on.

If you’re working with a 3PL, discuss their ability to scale and hold inventory. You want to be a reliable partner that they keep on. That requires you to strike a balance in terms of inventory, ensuring you can meet orders but understanding that long-term storage is causing issues for 3PLs and warehouse companies right now.

Create time to address systemic issues

Evidently, retailers are having difficulty attracting the best talent to retail positions. So, what can they do about this? In an article last year, we explored how technology can help improve the employee experience and thus retain employees. Employee experience technology can accomplish three major goals in retail talent management: increase productivity and goal accomplishment, improve employee agency at work, and help employees be more creative at work.

Perhaps the biggest supply chain takeaway from the COVID-19 pandemic is that many were built to withstand risks and threats in specific areas. When issues pushed beyond small-scale mitigation, supply chains started to buckle. Some faltered when overwhelmed across the entire chain while others had unrealized points of failure that only took light pressure to break.

Supply chain professionals and retailers need to start reviewing their operations systematically. Verify strength in each part and think about how that imparts reliability to the whole. Or see if areas with limited options are generating more significant risk. What many professionals once assumed were geographically limited threats have turned into global concerns.

Pandemic risks highlight systemic issues. Take the time to review what you’ve faced and where you’ve failed. Celebrate the parts of your supply chain that worked. Use those as guidelines for reviewing and improving gaps and potential. No one knows what the next black swan event will be, but we all now know that it has a chance to impact every aspect of our businesses and supply chains.

This guest article was written by Jake Rheud. He is the Vice President of Marketing for Red Stag Fulfillment, an eCommerce fulfilment warehouse that was born out of eCommerce. He has years of experience in eCommerce and business development.

Would you like to feature in our Retail insights section? Contact us today

It’s now been two years since the Covid-19 pandemic began to seriously disrupt business operations around the world. As a consequence, retail management has dealt with a range of problems including supply chain issues and store closures.

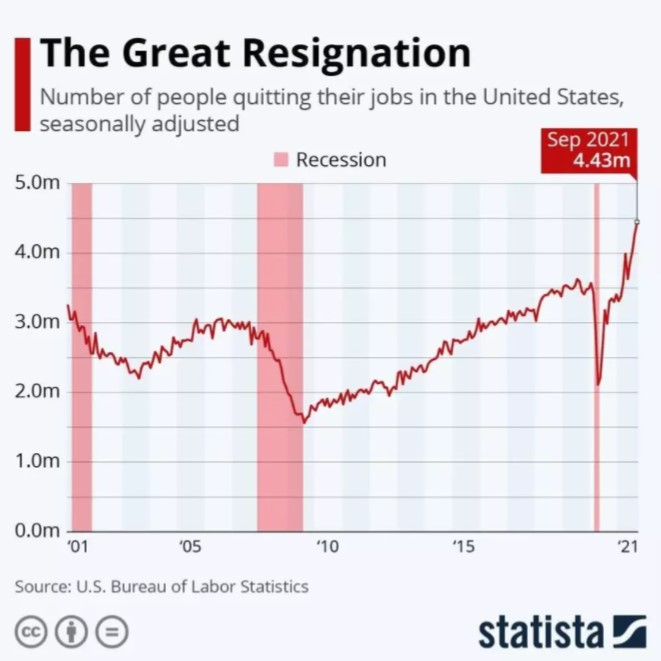

However, one additional problem that has been exacerbated by the pandemic is the ‘Great Resignation’. For the past two years, employees have left their jobs at an alarming rate – in the US alone, 4 million workers quit their jobs in July 2021. A survey of over 30,000 workers around the world found that 41% were considering quitting their jobs in the second half of 2021.

While the ‘Great Resignation’ has severely affected industries like healthcare and technology, the retail industry has not been immune. In August 2021, over 720,000 retail workers quit their jobs, second only to the foodservice and accommodation industry. As it stands, 96% of retailers say they are struggling to find store employees, and 88% said the same about hiring in distribution centres. In an industry that is still reacting to issues like supply chain disruption and wavering sales, this is a huge blow.

Ultimately, high employee turnaround is bad for business. There’s a clear correlation between happy employees, more satisfied customers, and higher sales; unhappy staff can result in the opposite. If retailers want to overcome the various issues that have plagued retail over the last two years, they need loyal, talented employees. But what is the solution to the retail talent management crisis?

Well, it could come in the form of retail inventory visibility software. Technology like RFID can have a huge impact on both the customer experience and an employee’s work, and retailers who implement this technology could find that it improves both their operations and their retail talent management.

The Great Resignation: How is it Affecting Retail?

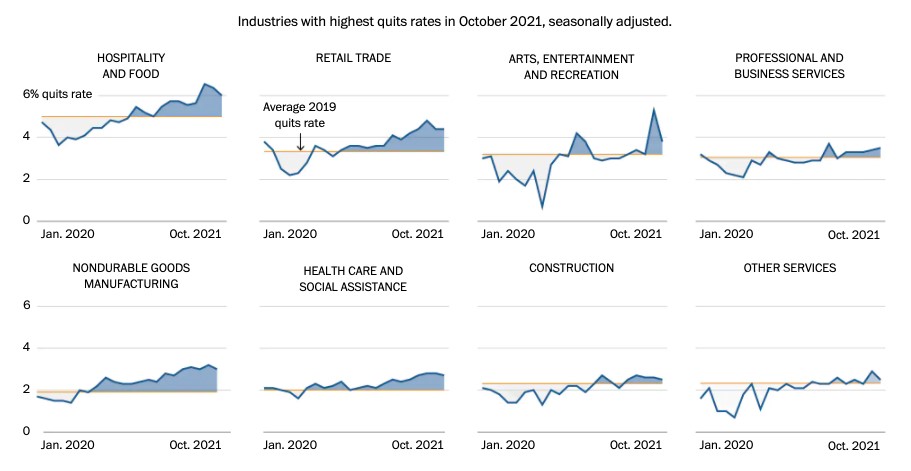

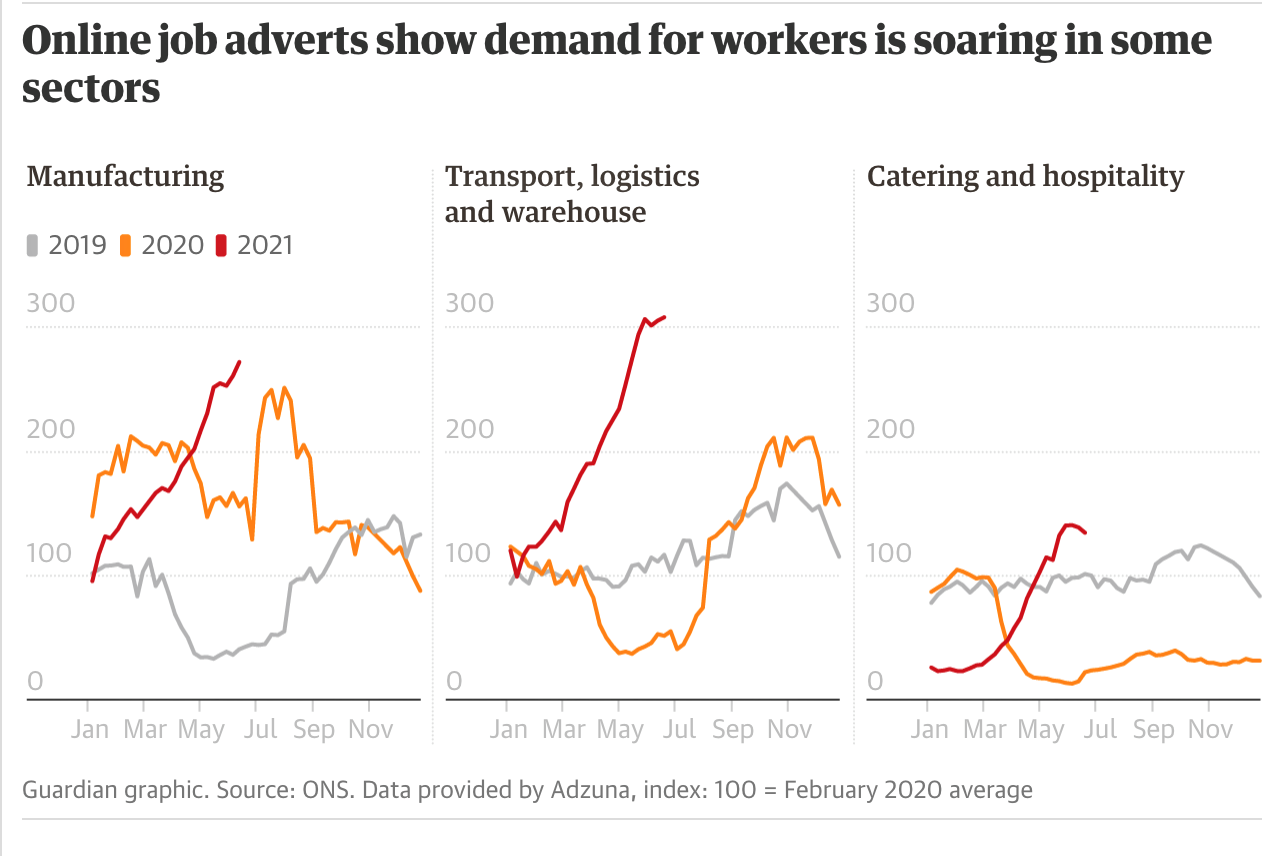

Over the course of 2021, workers across a variety of industries have been driven to quit their jobs. Record quit rates have been recorded in sectors like healthcare, social assistance, and nondurable goods manufacturing. However, while these industries have seen resignations come in waves, in retail, a talent management problem has persisted throughout 2021. For most of the year, the quit rate has been higher than the 2019 average, and while it reached a peak in the summer, the resignation rate continues to be higher than normal.

Undoubtedly, retail workers have had to adapt to difficult working conditions over the past two years. They may have had to work longer hours as companies try to recuperate lost profits during periods of closure. At the same time, their work environment has changed drastically as retailers take into account local public health advice including the use of masks and implementing social distancing in stores.

As we look towards a more normal year for retail in 2022, companies need to understand the Great Resignation and what is driving retail employees to quit. Ultimately, the biggest cause of retail resignations is stress. According to one survey, 26% of retail workers considered leaving their job in 2021 because of mental health concerns, and 5% had already left the sector because of stress-related issues.

Considering the multitude of problems that retailers have had to adapt to over the past two years, this is no surprise. But it also shows that retailers need to do more to prioritise employee wellbeing if they are to overcome the Great Resignation and outperform in 2022.

What are Candidates Looking For?

In order to succeed at talent management in retail, companies also need to know what employees prioritise when looking for a new role. Without this information, it can be difficult to attract talent to your retail business; something that is already an issue.

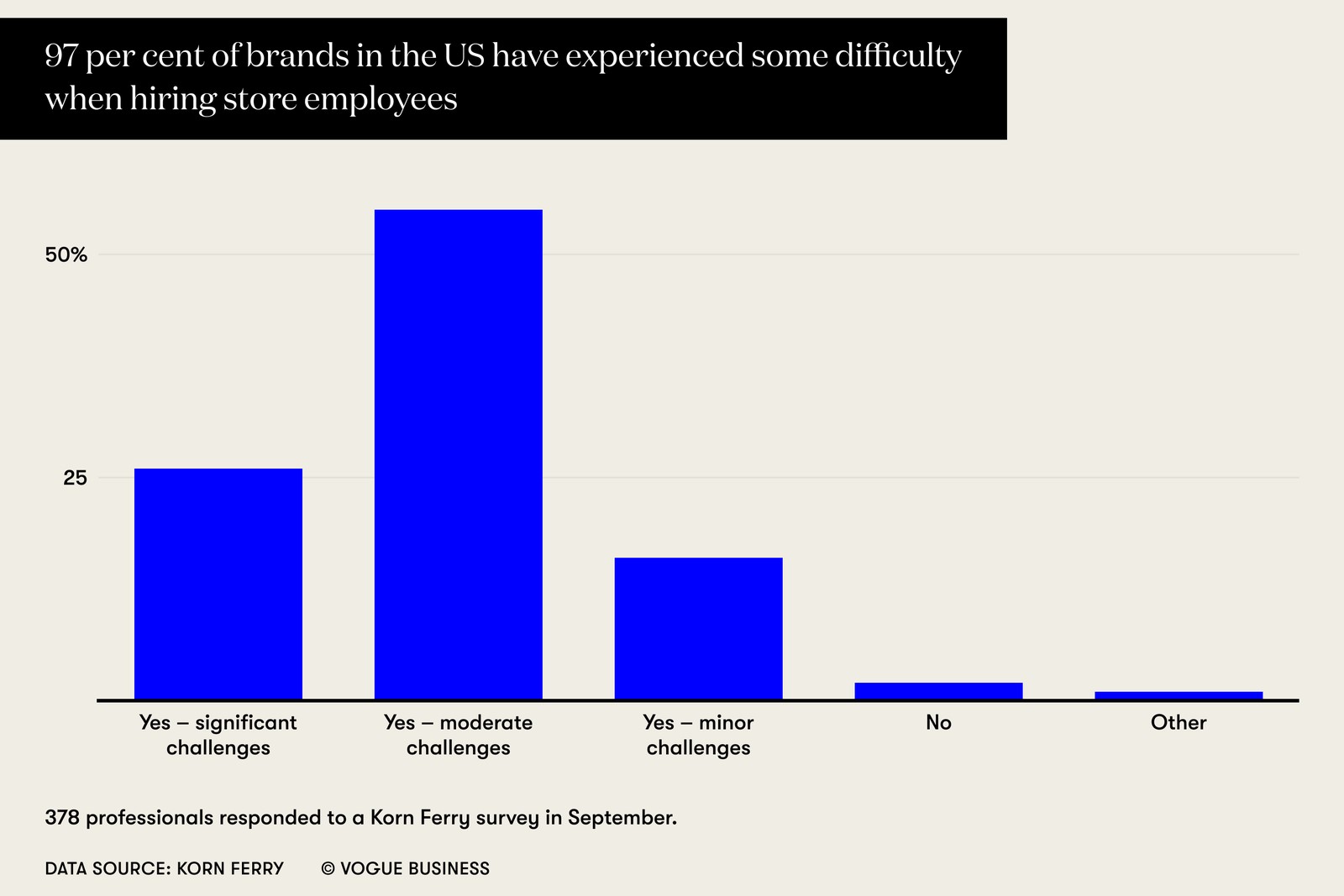

In the US, 97% of retail brands say that they have experienced difficulty when hiring new store employees. In an industry where there is already a shortage of applications and a growing number of employees are leaving their retail roles, it’s crucial that retailers can target applicants with benefits and considerations that they actually want.

Firstly, we know that retail workers are now prioritising their mental health at work. 84% of retail employees have said that their mental health has deteriorated over the past year, and this is evidently contributing to high quit rates in the industry as well as a reluctance towards taking jobs in retail. If companies want to attract the best candidates for in-store roles, as well as in distribution centres, they need to show that they care about employee wellbeing.

Part of this means establishing trust between retail management and workers and showing employees like shop floor staff that they can approach their work independently. Some brands have gone further, though. Retailer Gymshark recruited an entire mental health support team to provide support to workers. Potential retail employees are also asking companies to invest in their wellbeing long-term. This includes offering additional training to improve skills and offer opportunities for growth within roles.

Elsewhere, future workers are also reimagining how productivity is actually calculated. For many workers, it’s no longer about traditional metrics like sales and performance. Instead, retail talent management teams need to foster work environments that prioritise employee value over performance – that is, how much value employees provide to businesses outside of their output.

How can Retailers Attract and Retain Talent?

Evidently, retailers are having difficulty attracting the best talent to retail positions. So, what can they do about this? In an article last year, we explored how technology can help improve the employee experience and thus retain employees. Employee experience technology can accomplish three major goals in retail talent management: increase productivity and goal accomplishment, improve employee agency at work, and help employees be more creative at work.

As a result of the difficulty in retail talent management, some brands are already making changes to their HR operations. For example, over 30% of retail companies have already implemented higher salaries in order to attract retail talent to their businesses. Amazon introduced immediate sign-on bonuses of £1,000 in order to attract talent, targeting warehouse workers specifically. Walmart, on the other hand, has started offering weekly bonuses to its employees, which could pay out upwards of $200 per week.

Retailers with brick-and-mortar stores are also introducing additional employee benefits in order to drive store hiring. This includes wellbeing benefits that seek to improve the mental health of employees. In recent years, John Lewis has adopted new HR policies such as six months of equal parenthood paid leave for all staff and two weeks of paid leave if staff members experience the loss of a pregnancy. Other benefits that retailers are increasingly offering include flexible work hours.

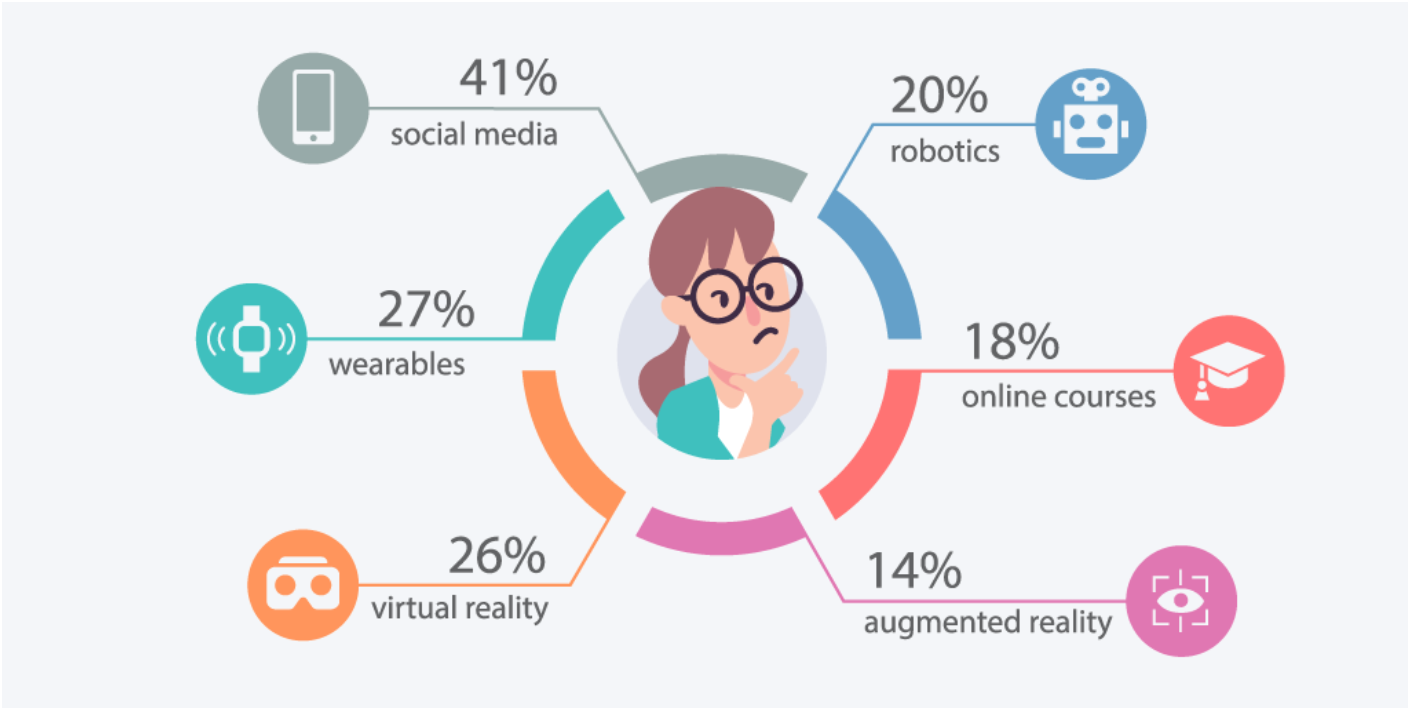

However, technology can also be utilised to help retain employees in retail. Studies show that staff increasingly want their employers to be invested in their work progress – 85% of people say that they want technology to help define their future. For example, 32% say that they want their employers to leverage technology in order to help them progress towards career goals.

One example of utilising technology to help support employees is with retail inventory visibility technology like RFID. Inventory visibility is crucial in retail – without a transparent view of stock, it’s difficult to implement omnichannel services or flexibly adapt to consumer behaviour. However, technology like RFID can also prove a valuable solution to retail talent management.

Empowering Employees Using RFID Technology

Not only is RFID technology a valuable inventory visibility solution in retail, but it can also help improve the employee experience and retain top talent. It’s important to note that the generation that are the latest big spenders, Generation Z, are also the generation that retailers will likely see applying to retail roles. Thus, they are not just retail consumers, they are also employees. With this in mind, technology like retail inventory visibility software can be a valuable way to hold onto these young employees and make them feel valued at work.

Digitising Operations

Firstly, owing to high digital literacy, this generation now expects processes to be digitised and automated, and may be less willing to persevere with outdated operations at work. One of these traditional operations in brick-and-mortar retail stores is physical inventory counts. This process, when performed manually, can require a huge amount of time and manpower. Repetitive procedures like manual stocktakes can also contribute to employee stress, especially if employees make errors, which is more likely with manual operations.RFID technology, on the other hand, can make manual stocktake a thing of the past and increase inventory accuracy to 99%. With RFID tags in each piece of stock, employees need only scan each product with a reader and can produce a full stocktake in around 30 minutes. This leaves employees feeling confident about their work and able to spend more time actually interacting with customers.

Improving Customer Experience

Similarly, customer experiences can also improve when retailers use inventory visibility software. As retailers recover from the effects of the pandemic, giving customers an optimal experience is more important than ever. Happy customers become loyal customers, and loyal customers lead to increased sales. 25% of customers switch brands more today than ever before, so attracting those who will keep returning is crucial.

Retail inventory visibility software, when used alongside an all-in-one mobile application, means employees can assist customers instantaneously with stock requests. In one survey, 42% of people said that ‘unhelpful staff’ was one of the main causes of a bad shopping experience, but businesses who take advantage of inventory visibility software in their retail operations can improve the chance of a better experience, as well as make employees feel confident at work.

Reducing Stress at Work

An all-in-one digital inventory visibility solution for retail can also reduce stresses on workers, leading to better productivity and reducing employee turnover. RFID technology can improve productivity and reduce the chance of stock delays and out-of-stock notices, leading to better interactions between employees and customers.

Retail inventory visibility software can also help managers make better staff decisions. With complete inventory transparency, it’s easier to see if there are going to be any supply chain issues. Instead of staff reacting to problems as they happen, which can cause undue stress if issues are completely unexpected, managers can plan for disruption. This can reduce the chance of staff working overtime or unexpectedly long hours and allow workers to focus on their day-to-day roles and the customer experience.

The Importance of Inventory Visibility for Retail

Aside from improving your retail talent management, there are many other reasons to consider investing in inventory visibility software for retail. Digitising processes like stock takes and making your inventory more transparent can have huge benefits to your business. These advantages can speed up operations, increase productivity, and improve the customer experience.

Additional benefits to implementing RFID technology include:

- Implementing efficient omnichannel services

- Increasing product availability

- Optimised supply chains

- Monitoring stock shrinkage

A fast fashion RFID solution

Stock accuracy, on-floor availability, and omnichannel applications in stores.

Book a demo with RFID to find out how our cloud-hosted RFID solution could help you improve your retail inventory visibility. Our multi-user app can provide intelligent stock takes and a smart in-store replenishment process and later, you can scale the solution to offer omnichannel services and effectively manage your entire store operations with real-time, item-level inventory visibility and analytics

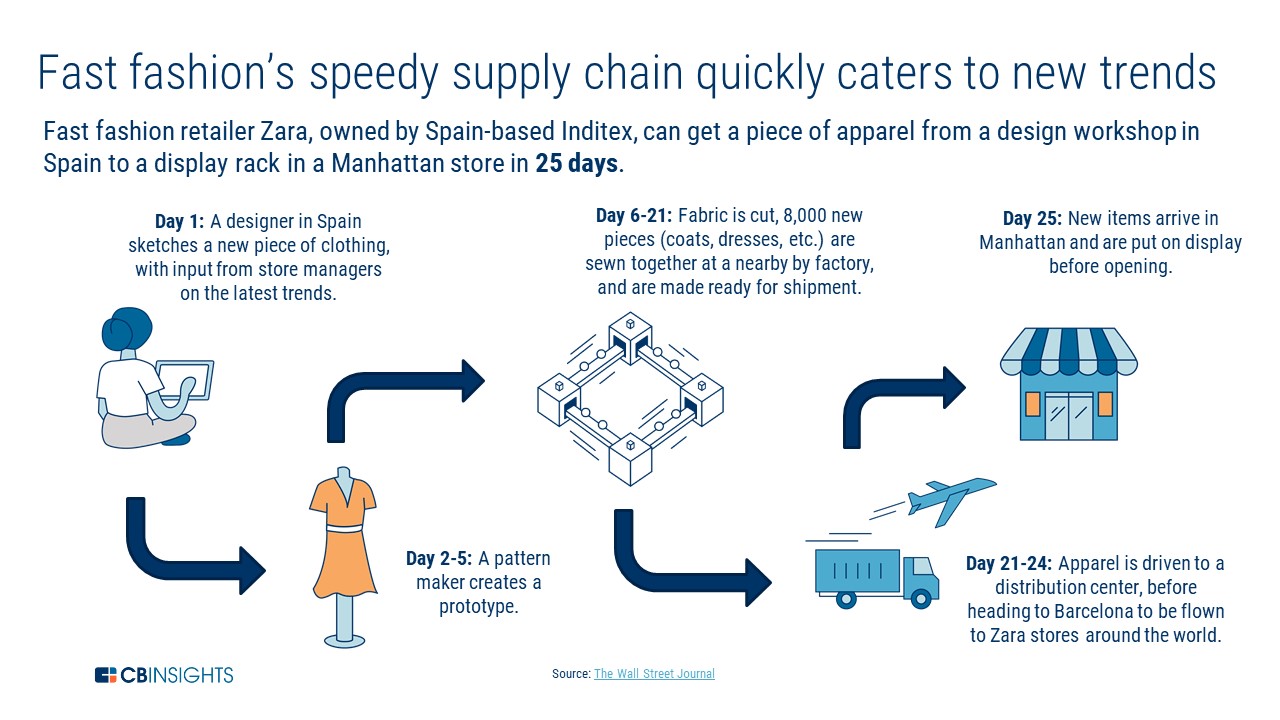

At the foundation of fast fashion is reliance on speedy, effortless supply chains. Thanks to developments in technology, brands can now produce thousands of pieces of new clothing in very little time – Missguided, for example, releases almost 1,000 new products every month. Consumers are attracted to brands who can reinvent their catalogues instantaneously and they expect brands to provide them with the clothing they want as soon as possible.

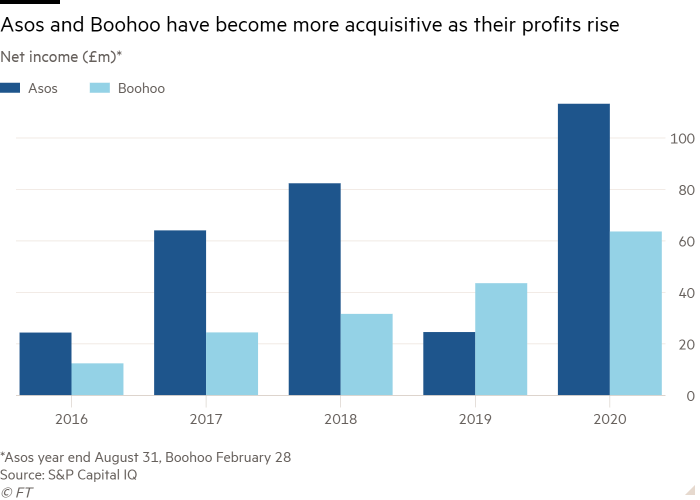

Generation Z, the generation now coming of age and holding increasing disposable income, love fast fashion. Over 50% of Gen Z shoppers purchase from e-tailers like Asos, Pretty Little Thing, and Missguided. Low prices combined with ease of ordering and immediate satisfaction mean these brands are only gaining in popularity. Sales at fast-fashion retailer Boohoo soared over the Covid-19 pandemic, growing 41%. In total, Boohoo generated £124.7m in profits between February 2020 and February 2021.

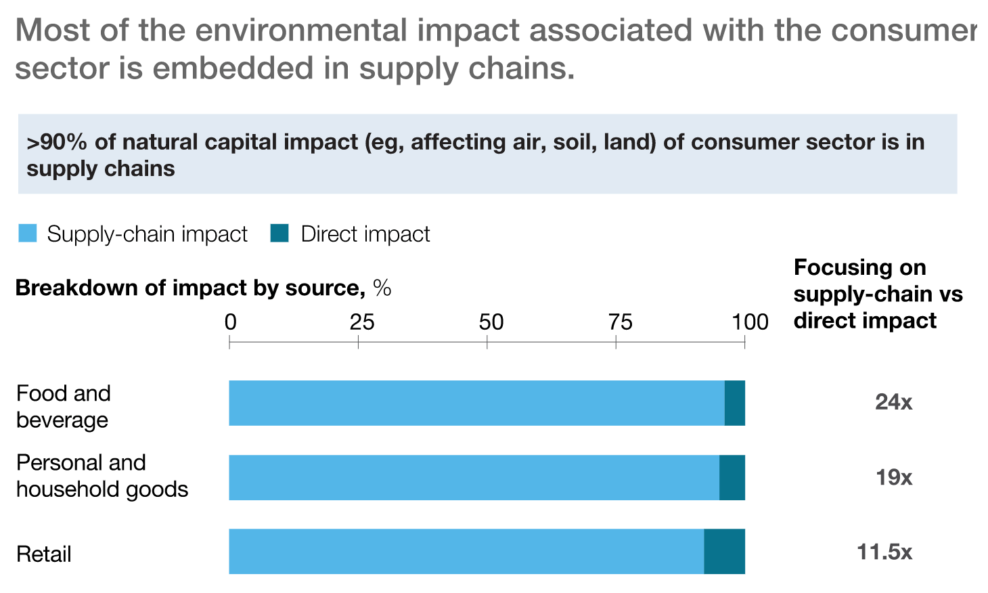

However, fast fashion is not without its problems. Consumers want their clothing increasingly cheaper and faster, but future global supply chain problems could hinder this. Additionally, fast fashion retailers are now confronting the environmental impact of the market. According to data from McKinsey, fast fashion is now responsible for about 4% of all global carbon dioxide emissions. By 2023, the emissions from textile production alone could increase by 60%.

When faced with the problems within fast fashion – both in terms of sustainability and supply chain optimisation – it’s clear that a solution is needed, and quickly. One viable retail solution is RFID, which could potentially transform the fast-fashion world. But why is RFID for fast fashion such promising technology?

Making Fashion Fast

As opposed to the historic seasons within fashion, fast fashion focuses on rapidly producing new styles at a rate of about 52 ‘micro-seasons’ per year. In 2019, the amount of clothing produced by global fashion brands totalled about 53 million tons, but this was expected to rise to about 160 million tons by 2050. Zara was one of the first brands to trial new bi-weekly deliveries of fashion inventory, and since then consumers have wanted clothes even quicker. Now, fast fashion brands are required to keep hundreds of pieces of stock on hand – either in-store or in distribution centres – to satisfy the constant need for products.

Fast fashion can also attribute its growth to the internet. Retailers with physical stores may see items go unsold – H&M had over $4 billion worth of unsold fashion inventory in 2018 and Primark were sitting on £1.5 billion of clothes in their warehouses. The flexibility of e-tailers, though, means that as long as they can get stock through the supply chain quickly enough, they can adapt to consumer trends. In comparison to brick-and-mortar fast-fashion retailers, brands like Boohoo often order only a select amount of stock, to see if it will sell.

This flexibility within the business model paid dividends when the Covid-19 pandemic hit. While clothing sales overall dropped by about 34% in the early months of the pandemic, internet retailers like Boohoo turned a profit. At the beginning of 2020, Asos predicted that they would make £30 million more than in a regular year due to the pandemic shift to online shopping.

The Problems with Fast Fashion

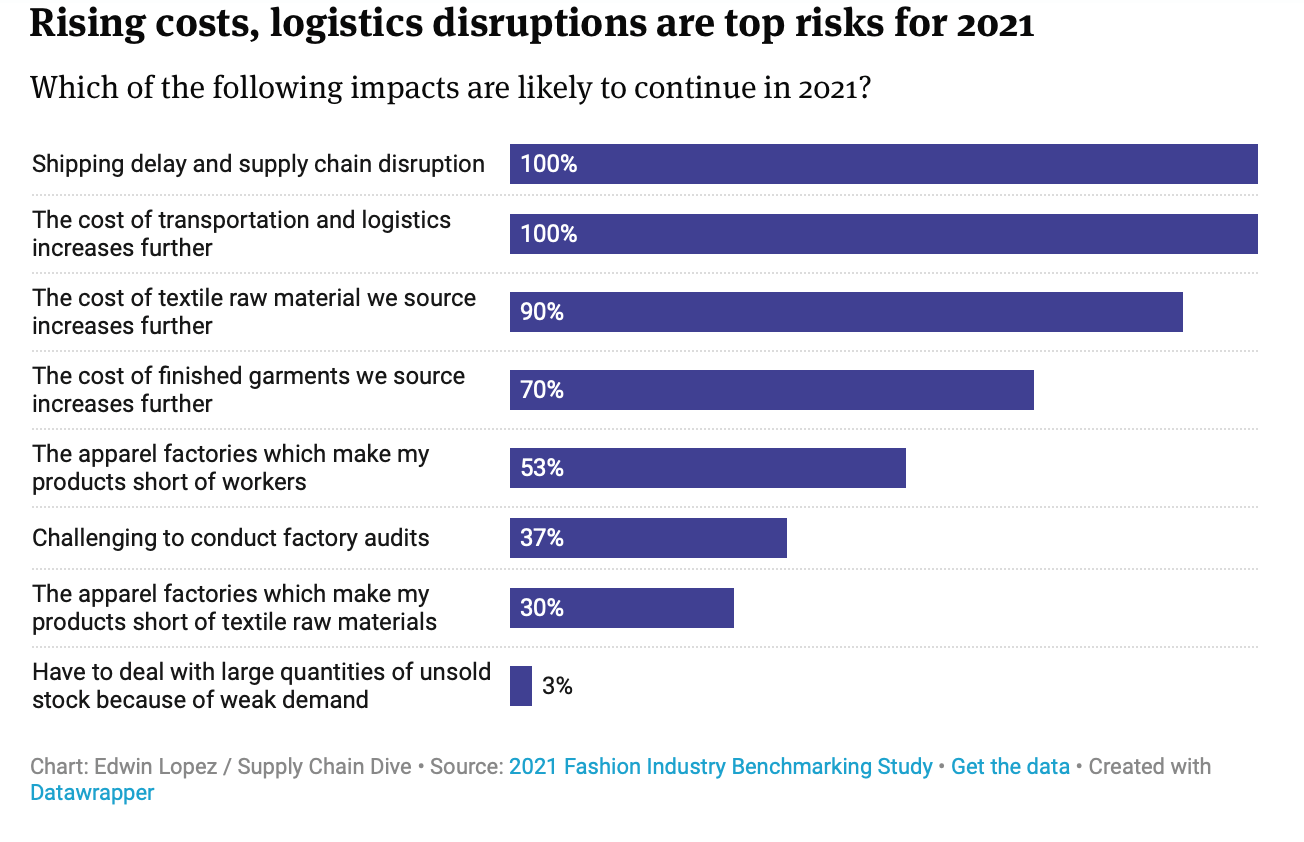

However, the rapid growth of the fast fashion industry has also exposed the flaws in this market. From supply chain crises to environmental impact, fast fashion has its downsides. Firstly, the industry relies on global supply chains, which is much riskier than keeping production closer to brick-and-mortar stores. Retailers had to confront this problem first-hand in 2021 when a trapped container ship in the Suez Canal caused an estimated loss of $9.6bn goods every day.

While not a direct result of the Suez Canal crisis, shipping costs have also risen dramatically over the last two years. Where a shipping container ship used to cost $1,500, it can now reach $15,000. Similarly, shipping times are also longer because of the pandemic, meaning it can take up to 8 months for stock to reach Europe from Asia. This is compared to about five weeks for production based in Eastern Europe. Consequently, many retailers are choosing to forego global supply chains and low-cost manufacturing processes in Asia and “nearshore” their production closer to home.

Aside from supply chain disruption, fast fashion’s biggest problem relates to its environmental impact. While the fashion industry as a whole has its sustainability issues (it can take 10,000 litres of water to produce 1kg of cotton, for example), fast fashion is particularly problematic. The quick turnaround of fashion inventory in the fast fashion industry means more waste and the increased use of raw materials.

In total, 84% of all discarded clothing ends up in landfill sites; and while 95% of textiles could be recycled, the fast fashion model doesn’t encourage recycling or reworking. What clothing does get donated to second-hand clothing stores or thrift shops has a similarly doomed life – the United States exports over one billion pounds of used clothing every year, most of which gets sent to used clothing markets in Sub-Saharan Africa. Due to the sheer quantity of products, fast fashion also doesn’t have the supply chain transparency to accurately track where products have come from and where they end up.

The Environmental Impact of Fast Fashion: Consumer Reactions

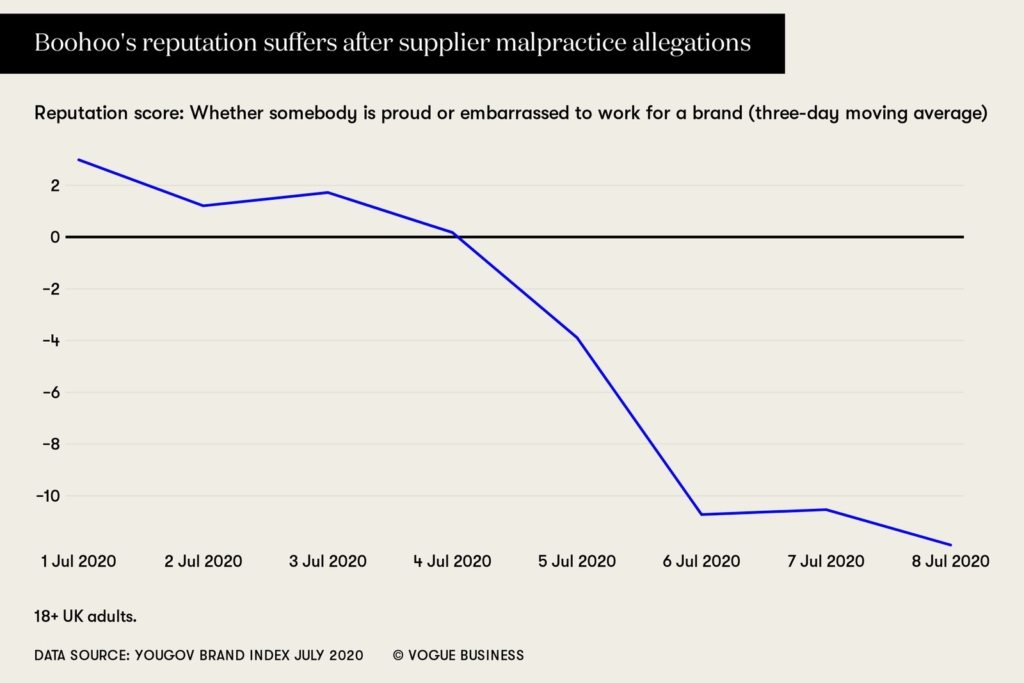

But do shoppers really care if the fast fashion industry is unsustainable? Well, the answer is both yes and no. In 2020, retailer Boohoo was investigated after it was hit with allegations of exploitation related to its factory in Leicester. According to reports, workers in the factory were being paid just £3.50 an hour to make clothing. However, consumer reactions to the news were lukewarm. Despite the company’s reputation taking a sharp hit in the months after the report was released, over half of Gen Zs said they would still buy clothing from Boohoo-owned fast-fashion retailers.

On the whole, though, consumers are reacting to news of unethical and unsustainable practices. A McKinsey report reveals that 1 in 3 consumers have stopped buying from particular brands because of sustainability concerns. 40% of respondents also said that they have actively started buying from clothing companies with a good sustainability record. However, there were still limits to how sustainably consumers can or want to be. 46% of people said that additional information about the origin or sourcing of products would help them to be more sustainable, and 50% wanted more recycling options for used products.

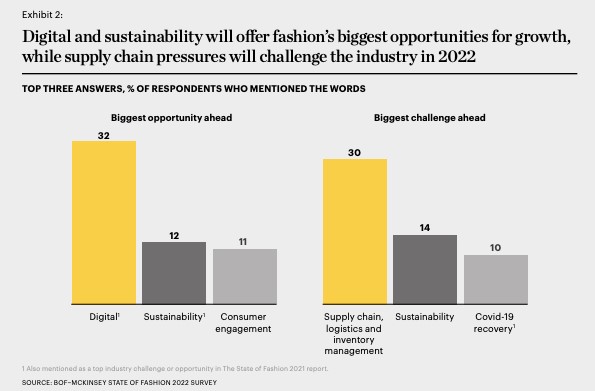

15% of fashion industry executives say that sustainability is one of the top challenges for them in 2022. However, supply chain logistics are perceived as an even bigger threat to the industry, with 30% of respondents citing fashion inventory management or logistics as one of their top three concerns. Any future fast fashion retail solution will have to address the combined issues of supply chain disruption and sustainability – and implementing RFID in fast fashion could achieve this.

The Benefits of RFID for Fast Fashion

So, what’s the retail solution for fast fashion’s problems? Well, fast fashion retailers could turn to RFID to tackle both sustainability issues and problems in their supply chain. RFID in fast fashion is nothing new – Zara has already invested in digital tags in their supply chain network and full integration of RFID across their network was completed in 2020. However, the technology is rapidly decreasing in cost, meaning there’s a huge potential payoff for retailers who invest in fast fashion RFID technology today.

Transparency

If fast fashion retailers are to prove that their products are from entirely sustainable sources, they will have to embrace transparency in their operations. Consumers now want to know where their products come from, and whether they can trust sustainable labels on clothing.

For fast fashion, RFID can be the retail solution to transparency. Only with accurate data and information about supply chains can retailers provide honest and open updates about their fashion inventory and ethics.

Fashion inventory visibility

Real-time visibility is important for any retailer, but even more so in the fast fashion industry. Only when you can track stock in real-time can you adapt to shortages and delays. RFID in fast fashion offers a way to accurately track stock through the supply chain, allowing retailers to make more accurate decisions and identify problems.

When fashion inventory is tagged at the point of production, its journey can be traced throughout the supply chain to a high degree of accuracy. It’s also possible to scan large amounts of stock at once, making the process straightforward and offering instantaneous data. RFID can also make supply chains more resilient by revealing weak points in operations. As a result, decisions affecting the supply chain can be made more quickly and with accurate data to back them up.

Returns

We know that consumers are asking for options regarding recycling initiatives and returns policies in order to make their clothing consumption more ethical. With customers increasingly turning to online ordering, the returns process has become more complex for stores, as they need to offer options to post from home or return to store. RFID in fast fashion solves this problem, letting retailers know exactly where a product is at all times.

RFID is also a way for retailers to embrace sustainable options like fashion rental. When RFID tags are implemented on all fashion inventory, it’s easy to implement returns and even categorise clothes for washing after they’ve been returned.

Sustainability

RFID in fast fashion can also boost a retailer’s overall sustainability by improving the accuracy of stock takes. Knowing exactly which items are selling and which aren’t means that retailers can adapt quickly to consumer demand, and only order what will sell. There is a huge problem with inventory loss in the fashion world, but this can be solved with accurate data. With RFID, fast-fashion retailers can only order the inventory they need and be assured that they won’t run into out of stock notices because of the technology’s accuracy.

The Future of RFID in Fast Fashion

There’s no doubt that, despite its drawbacks, fast fashion will continue to be popular, especially among younger generations who often are blind to the environmental impact of the fashion market. Many fast fashion brands are already making changes to their business models in reaction to issues like sustainability. Inditex, which owns Zara, Bershka, and Pull&Bear, has said that 100% of their cotton, linen, and polyester will be from sustainable sources by 2025. H&M is vowing to improve the percentage of sustainable or recycled materials they use from 57% to 100% by 2030.

While these initiatives will undoubtedly make brands more sustainable, they are also complex and high-cost. If brands are looking for a low-cost, high-return way to boost their ethics and improve their reputation, RFID in fast fashion is an ideal retail solution.

A fast fashion RFID solution

Stock accuracy, on-floor availability, and omnichannel applications in stores.

Book a demo with Detego to find out how our cloud-hosted RFID retail solution could help you optimise your approach to fast fashion inventory. Our multi-user app can provide intelligent stock takes and a smart in-store replenishment process and later, you can scale the solution to offer omnichannel services and effectively manage your entire store operations with real-time, item-level inventory visibility and analytics.

The past two years have been undeniably difficult for retailers. From reduced footfall in physical stores to grappling with staff shortages, there have been few advantages, and many long-term effects, to the recent disruption. The same is true for supply chain issues that have beleaguered retailers over recent years. Businesses have had to adapt to problems including shipping delays, higher delivery costs, and fluctuating consumer demands, and though we’re seeing the first signs of economic recovery, these issues won’t disappear overnight. Some analysts have predicted that it could take until mid-2024 for supply chains to return to relative normal.

So far, retailers have been forced to react to supply chain disruption as it happens, flexibly accommodating their business operations to the issues. However, there are ways for retailers to turn supply chain issues to their advantage, and the solution involves retail inventory management software.

Most businesses will already have some form of retail inventory management process; it’s a crucial part of omnichannel retailing, for example. But technology like RFID combined with powerful inventory software can offer a way for retailers to not only adapt to supply chain disruption but conquer it.

The Current Supply Chain Issues

The fallout from the Covid-19 pandemic is still being felt in global supply chains. While retailers have weathered the worst of the storm with regard to inventory delays, there are still challenges in the global supply chain that will inevitably take time to remedy. In fact, 94% of Fortune 1000 companies are still experiencing supply chain disruptions as a result of the pandemic.

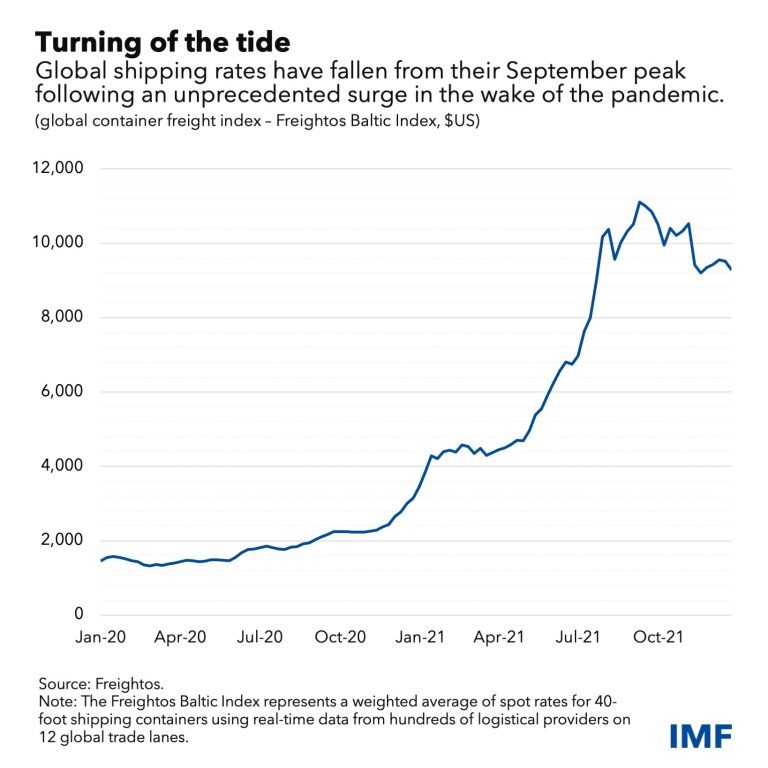

One of these major challenges is the cost of shipping. Global shipping costs spiralled in 2021, reaching a peak in the latter half of the year. In October, the average cost of shipping a standard 40ft container reached $10,000. Costs have since declined by 16%, but are still higher than in normal years – in some cases by more than four times the average. In 2019, the cost of shipping a container from Shanghai to New York was $2,500, but this has since risen to $15,000.

As well as increased costs to ship inventory from manufacturer to store, retailers also have to adapt to delays in shipping. The global supply chain is still adapting to Covid-19 setbacks, resulting in persistent delivery delays. At present, there are 20 million containers waiting at ports all over the world, and this backlog will take more than a few months to resolve. While the scale of the issue doesn’t compare to early 2021 – when supply chain delays and shortages were up 638% – many businesses will still be experiencing shortages or delays well into 2022.

Finally, there has been a shift towards more environmentally-friendly practices in a wide variety of industries. Companies are also looking at ways to make their supply chains and logistics more sustainable. This includes switching to more sustainable shipping options like biofuel instead of diesel, eco-driving, or moving operations closer to customers. However, a move towards sustainable operations is challenging and requires coordinating entire supply chain operations and more complex retail inventory management.

Outperforming During Disruptions

Despite ongoing supply chain troubles, some retailers have done more than just endure the issues – they have thrived on the disruption. Brands like Walmart, M&S, and Pets at Home have all posted strong growth over 2021, despite grappling with intense supply chain disruption. The one thing these brands have in common? Omnichannel retail.

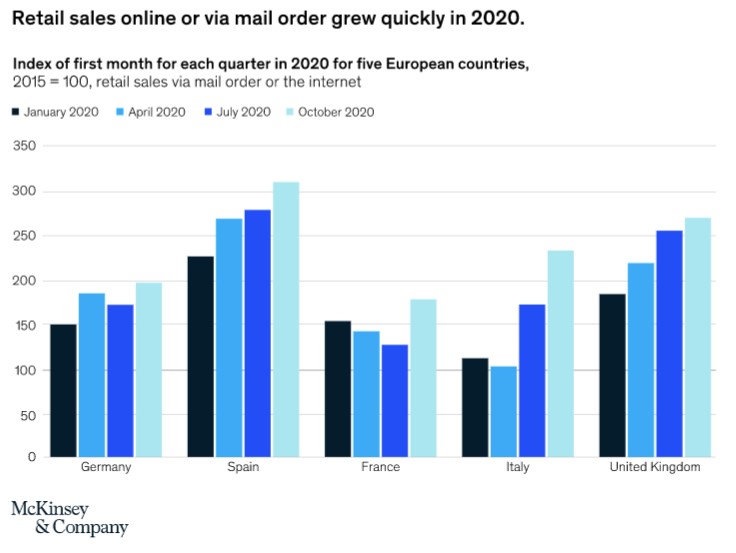

Over the last two years, consumers have switched from in-store shopping to online shopping. There was a pronounced switch to online retailing in 2020, which then persisted throughout 2021. In the UK, online sales made up 30% of overall retail spending in 2021. While still less than a third of overall spending, this is a jump from the 11% of sales that were conducted online in 2019.

However, for many retailers, it wasn’t simply a question of turning attention to online sales. Instead, an omnichannel solution that combined in-store shopping and online options proved the most effective option. Nike, for example, continued with plans to open a flagship store in Paris during the pandemic. Instead of floundering as footfall in brick-and-mortar stores fell, they found that the physical store also helped drive online sales. Retailers who open a new physical location can see a 37% increase in traffic to their website in the following quarter.

For some companies, it was a question of evaluating their supply chains and seeing where they could improve. Sports brand SylvanSport ran into issues when their overseas tire manufacturer couldn’t deliver on time, so they had to look at alternatives. This included seeking domestic manufacturers to create the product for them while still retaining their overseas manufacturer for future orders. This flexibility within their supply chain allowed them to easily adapt to any issues as well as future-proof their operations in case of further disruption.

How to Adapt to Disruption

It’s clear that supply chain challenges aren’t going away anytime soon. Consequently, retailers must plan for periods of disruption and find a way to come out of them performing stronger. For a start, we know that retailers who have outperformed during the last two years have focused on a few things: omnichannel solutions, consumer trends, and real-time data.

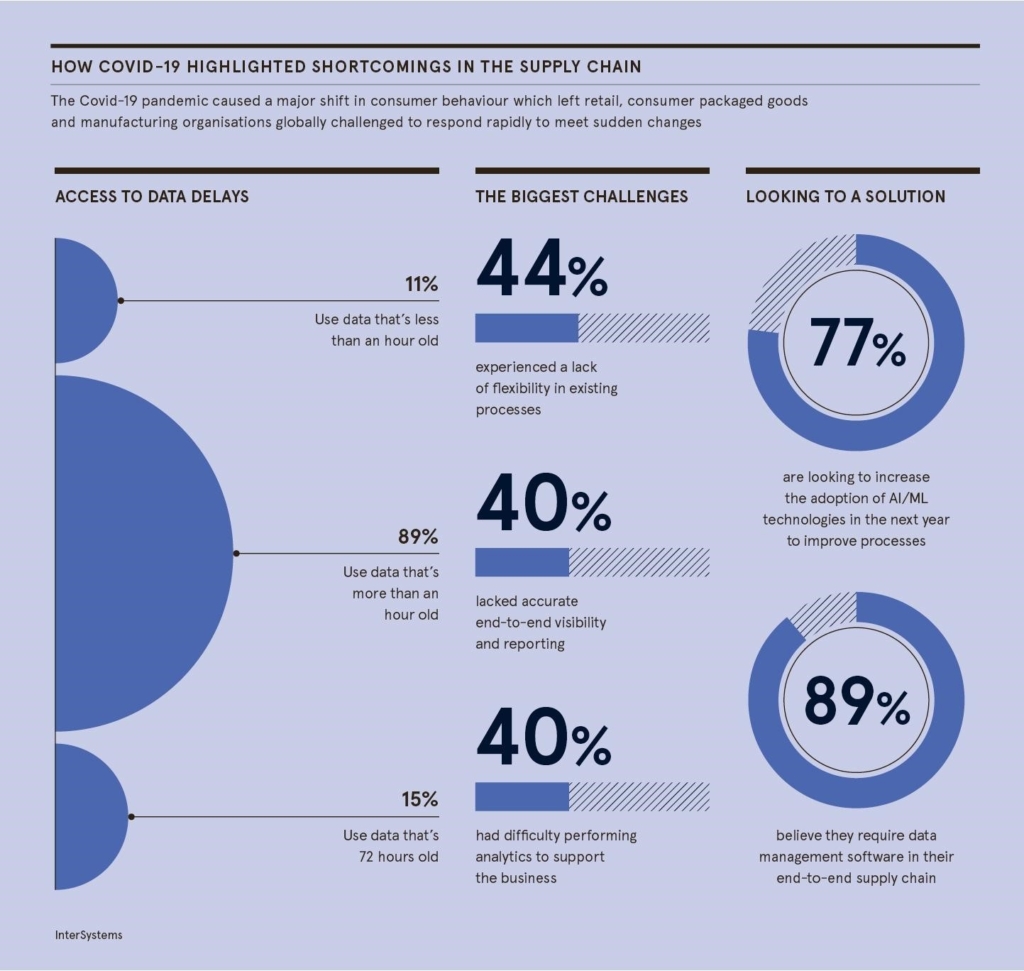

Data is a powerful tool when it comes to adapting to supply chain disruption, but many retailers aren’t taking advantage. In fact, 54% of company executives have said they don’t have clear visibility of their supply chain past Tier 1, and an additional 40% of companies don’t have accurate end-to-end visibility and reporting. This means that any disruption in the early stages of their operations will go unseen, and the consequences felt only when it’s too late.

However, companies are learning that technology like retail inventory management software is a powerful way to improve their operations – 89% of retail organisations said they will need to implement data management software in their supply chain.

Companies that do turn to AI-powered data solutions inevitably become more resilient. Having a clear understanding of supply chains, and their weaknesses in them can make companies more able to adapt to difficulty when it arises. When Japan was hit by a magnitude-9 earthquake in 2011, production at Toyota’s factories ceased for two months. After this, they focused on building an accurate database of their suppliers and parts to track their operations and products through the supply chain. In 2016 and 2019, when more earthquakes hit Japan, Toyota had reduced their production stoppages to just two weeks.

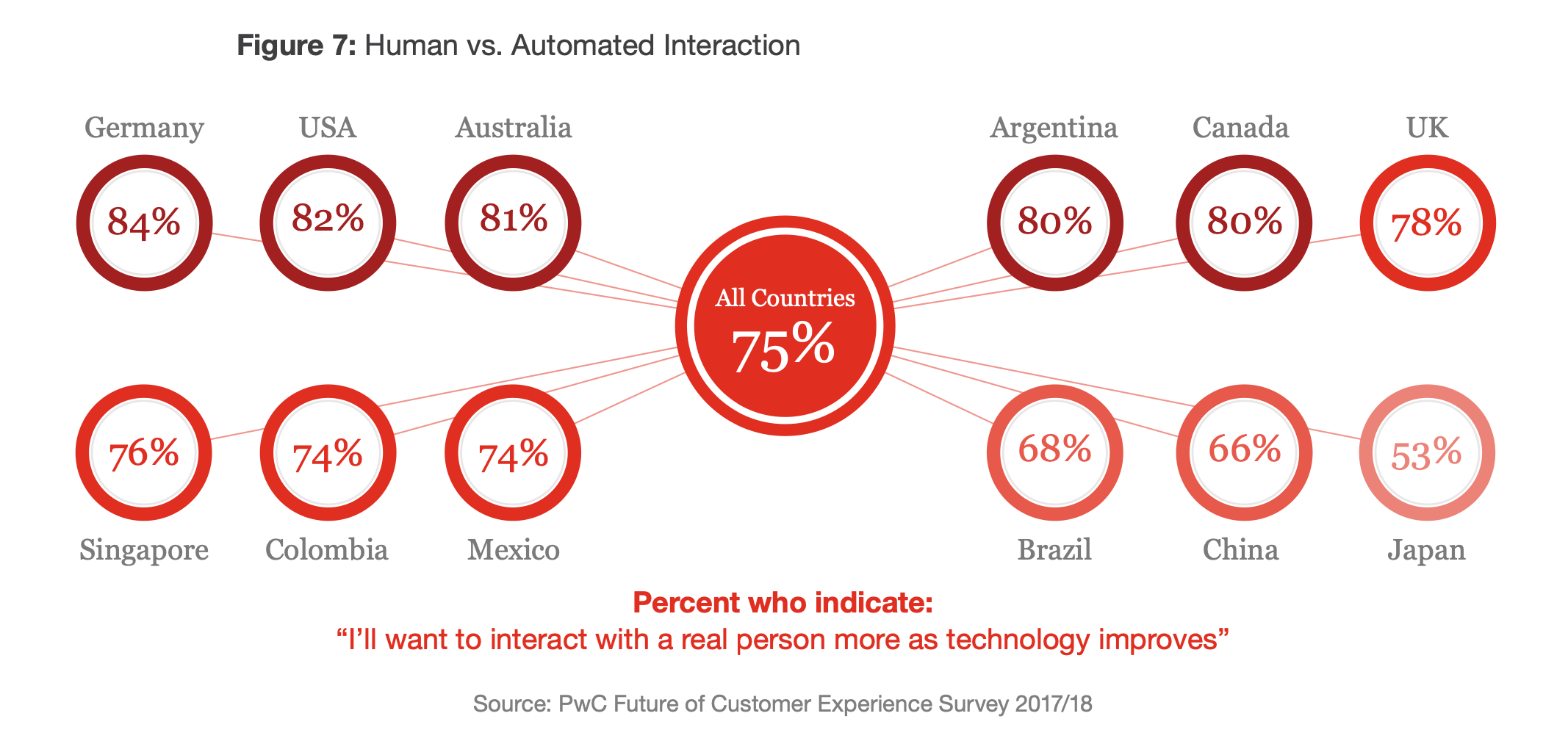

We also know that omnichannel services are the way forward for modern retailers. Consumers are asking for alternative ways of purchasing products, and omnichannel retailing also paves the way for future technology like AI-powered brick-and-mortar stores and virtual shoppers.

Since the beginning of the pandemic, one-third of American shoppers have taken advantage of omnichannel services including deliver-to-store, and two-thirds of those shoppers plan to continue taking advantage of omnichannel retailing in the future. As the previous example from Nike demonstrates, it’s not about turning 100% to online services, but about offering multiple opportunities for consumers to purchase products.

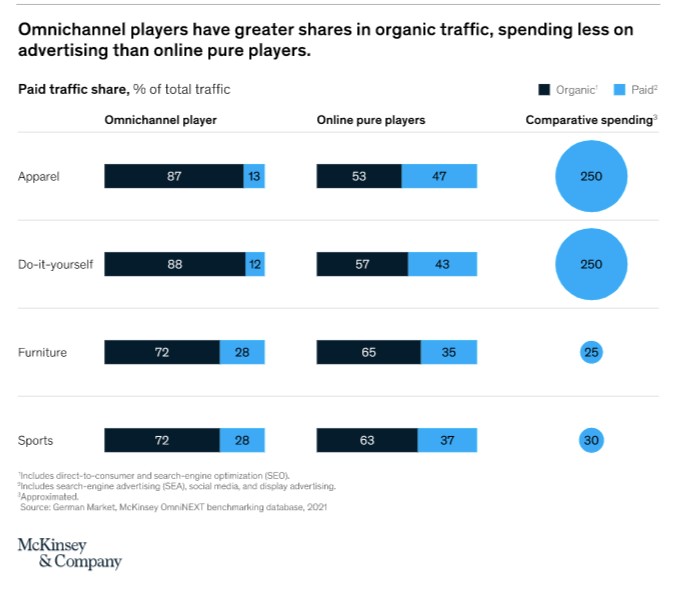

According to a study from McKinsey, brick-and-mortar retailers – though at a disadvantage over the last two years due to a decrease in footfall – still have to spend comparatively less on advertising in order to reach the same amount of customers as online retailers. So, it’s about developing an approach to omnichannel that blends online and physical retailing, allowing customers to purchase exactly when and how they want.

The final way retailers can increase the resilience of their operations and their supply chains is by paying close attention to changes in consumer behaviour. Arguably the biggest consumer trend for 2022 is a shift towards sustainability. In 2021, one in three consumers stopped buying certain brands because of sustainability or ethical concerns, and 46% of consumers wanted additional information over the origin of their products. To retain consumers in the coming years, it’s crucial that brands consider the environmental impact of their supply chains and make the necessary changes before customers choose alternative products.

The Benefits of Retail Inventory Management Software

We’ve identified three ways to turn supply chain disruption to your advantage: developing an omnichannel strategy, harnessing the power of digital insights, and staying aware of consumer trends. For all of these strategies, it’s crucial that companies dedicate some time to reviewing their retail inventory management system. Without a successful system in place to track and count inventory, you won’t be able to implement omnichannel services or make changes to your supply chain in reaction to consumer trends.

In order to accurately track inventory and respond to supply chain disruption, companies should consider investing in retail inventory management software. An all-in-one retail inventory management software, with the help of RFID tags in your supply chain, can provide businesses with real-time insights and inventory flexibility to increase supply chain resilience.

Real-Time Insights

An all-in-one retail inventory management software offers retailers real-time insights that can transform operations. While digitising your entire supply chain might seem like a mammoth task, RFID supply chain technology is becoming more accessible and easy to implement.

In particular, the ability to monitor supply chains at all times, and receive real-time data from supply chains, makes it easier to make operations decisions fast. When the container ship, the Ever Given blocked the Suez Canal last year, 15% of the world’s freight was impacted. Implementing solutions quickly became of the utmost importance – only companies who had immediate insights into the effect of the crisis on their operations could make decisions to avert supply chain disasters.

Retailers that had already implemented a retail inventory management solution could immediately make decisions to shock-proof their operations from the disaster and recover more quickly.

Supply Chain Visibility

In order to adapt to disruption, it’s important that businesses have a clear, end-to-end view of their operations. However, many businesses currently don’t have the level of supply chain visibility necessary to quickly adapt to disruption. Retail inventory management software, when paired with RFID tags in the supply chain, can give businesses the visibility they require to outperform.

Only with a clear view of the supply chain from manufacturer to store can businesses accurately see where their stock is and react to shipping errors or delays. This is even more crucial as businesses turn to omnichannel experiences to boost sales, where it’s crucial to see where stock is and ensure that other services like ship-to-store or store pick-up can happen successfully.

Not only does retail inventory management software offer businesses end-to-end insights into their operations, but it can also help with sustainability efforts by enabling operations to be fully transparent to consumers.

More Accurate Inventory Counts

Implementing RFID in your supply chain can also make it easier to get accurate inventory counts. When there’s a disruption to inventory deliveries, knowing exactly what stock you have can make a big difference to your sales and allow store changes to be made swiftly. When used alongside a retail inventory management platform, RFID tags can help achieve 99% stock accuracy.

RFID technology enables retailers to quickly see which stock may incur delays and prepare for potential out of stock notices. For example, Reiss increased their sales by 4% by increasing their stock accuracy as they had an accurate view of exactly what stock was available and where. This makes it easier to implement omnichannel strategies like buy-online-pick-up-in-store (BOPIS). With accurate stock counts, it’s also easier for retailers to quickly adapt to consumer trends, focusing their attention on only the stock that is selling well.

Retail inventory management solution

Stock accuracy, on-floor availability, and omnichannel applications in stores.

Book a demo with Detego to find out how our cloud-hosted retail inventory management solution could help you outperform competitors and adapt to supply chain disruption. Our multi-user app can provide intelligent stock takes and a smart in-store replenishment process and later, you can scale the solution to offer omnichannel services and effectively manage your entire store operations with real-time, item-level inventory visibility and analytics.

Detego and Microsoft partnered on this retail success story.

How an iconic British fashion brand and retail store chain successfully increased the availability of items in-store while improving the customer experience.

“It was also around gaining visibility for our omnichannel journey. If you look at those as different challenges, RFID provided a solution that enabled us to use technology to enhance all that.”

Complete the form below to download the case study.

Consumer mindsets are evolving at an accelerating pace.

While it wasn’t long ago that shoppers could be satisfied receiving the tiniest of details from a product’s journey before it came into their possession, years of unsustainable and unethical practices within retail supply chains have begun to tarnish the relationships between businesses and their customers.

Understandably, customers are increasingly demanding that the traditionally opaque supply chains that serve them are made more visible – and they’re using their wallets to back and promote these values. As a result, power has shifted, and unless retailers want to become obsolete, ignorance and dishonesty must be replaced with clarity and accountability.

Especially since — over the past 18 months — the pandemic has intensified this scrutiny, and it seems that now, for retailers to survive, they must relinquish their use of transparency as a novel marketing strategy and view it as a necessary process to be implemented into everything they do.

Transparency as a marketing tool is nothing new, businesses have been branding their performance as a method of storytelling that highlights their morality and pulls audiences in for a while now. Greenwashing, however, has become a concerning result of this trend, with companies picking and choosing what to report and positioning their activities in a positive light.

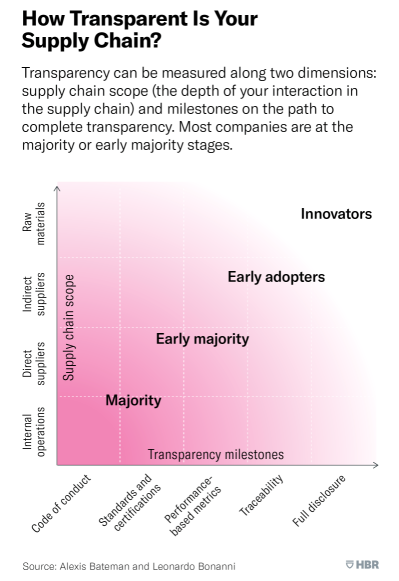

In fact, in the Business of Fashion’s and McKinsey & Company’s The State of Fashion 2020 report, almost 20% of executives claim that radical transparency is one of the top three themes impacting their business due to changing consumer desire for genuine and clear information.

What Does a Radically Transparent Supply Chain Look Like?

Radical transparency defines the complete disclosure of information at every link of a retailers supply chain. This includes everything from the sourcing of raw materials, water usage in textiles dying, factory working conditions, the environmental impact of goods distribution, and customer care instructions.

In the past few years, many organisations have led the charge regarding supply chain clarity. For example, in just the apparel sector exists Fashion revolution Eco-Age and Good on you – all of which currently hold fashion retailers accountable over the impact of their supply chains by taking different approaches to the promotion of reporting.

And reporting is the cornerstone of supply chain transparency, providing a window into the practice’s businesses abide by. H&M — leaders in supply chain transparency — are among many retailers who have aligned their manufacturing reporting with Transparency Pledge Reformation takes this a step further, making the environmental impact and traceability of their products public.

Yet, the widespread adoption of end-to-end supply chain clarity is limited and slow. While most businesses have begun to embed transparency into their internal operations and with direct suppliers, processes beyond their control – for the most part – remain opaque.

As a result, the companies that can trace their products’ raw materials are categorised as pioneers of supply chain transparency, whilst businesses that can track the activities of their indirect suppliers are ahead of the curve. Yet, for the majority of companies, moving towards full disclosure reporting can seem like an impossibly far milestone to reach. Nonetheless, it is one they must begin striving towards now.

Why Prioritise Transparency Now?

While many retailers readily look to improve their supply chain transparency, for many others, full-disclosure reporting is a practice being pressured upon them by both direct and indirect stakeholders. These different parties desire open and honest information for various reasons. Here we discuss the mindsets of these stakeholders and explore the reasons behind their demands for radical supply chain transparency:

1. Customers

The post-pandemic retail sector is filled with innovation that attracts the re-emerged consumer whose activism has been heightened by COVID-19. Multiple lockdowns had given the world time to re-evaluate its values, especially when last year, there was no good excuse to look away from societal issues that took the world stage, such as climate emergencies, poor factory conditions, and racial injustice. As a result, contemporary consumers are more scrutinising now than ever before and want the businesses they shop with to take accountability when problems within their internal operations are uncovered.

Sustainable and Ethical Practice:

It is arguably customers who drive retail’s interest for heightened clarity through their passion for advocating brands with sustainable products and ethical operations. In fact, 64% of shoppers look for ethical or sustainable features when making a purchase, and according to researchers at MIT Sloan School of Management, they may be willing to pay 2% to 10% more for products from companies that provide greater supply chain transparency.

In being able to see the impact of their purchases more clearly, customers are not only able to build trust with a retailer but become more assured that their own behaviours align with the values they hold.

Omnichannel:

Customer-centricity is key to post-pandemic supply chain success as demand for goods becomes increasingly uncertain and erratically patterned. The growth of omnichannel means that shoppers expect retailers to cater to them at the physical and digital touchpoints they more fluidly move between in the wake of the pandemic.

By improving the transparency of their supply chains, retailers could much more readily provide the services created by the omnichannel shopping experience, such as real-time inventory visibility and same-day delivery fuelled by digitisation.

2. Employees

Employees are core stakeholders that the shift towards transparency would most impact. Making their working environments unambiguous and their everyday tasks clear to external audiences allows employees, customers and investors to hold retailers accountable in a public domain.

Welfare: According to Anti-Slavery International, there are 16 million people trapped in forced labour within the supply chains of businesses that supply our goods and services. Supply chain transparency is a small step to providing workers more protection over workplace conditions, wages, and personal agency, helping mitigate the risk of external suppliers taking advantage of labour in the sector.

As a result, by enhancing supply chain transparency, businesses are able to track the social impact of their operations and shine a light on grey areas within their own chains that they may not have complete control over.

3. Investors

Last year, Boohoo lost more than 1.5 billion euros in market value after it was uncovered that workers manufacturing their products earned less than minimum wage in poor working conditions. So making it clear that now more than ever, customers aligning their purchases with their values will have a tangible impact on revenue.

Return on Investment: For investors, the intrinsic link between supply chain controversy and loss in market value is a concerning risk. For example, violations in ESG practices were estimated to have erased almost half a trillion dollars’ worth of value from public companies from 2015 to 2019. ESG stands for environment, social and governance. All three domains increasingly feed into an investors decision to back a company beyond financial projections.

So, with investors progressively looking to work with businesses that have a positive impact, transparency is a firm method of proving compliance with every step of the EGS chain that can easily be mapped to the supply chain.

Transparency and Visibility: One Cannot Exist Without the Other

Now that we have made a case for supply chain transparency, there is still the question of how these typically tangled and murky operations can become crystal clear when only 13% of retail executives currently describe having end-to-end visibility.

Although often and mistakenly interchanged for one another, transparency and visibility are two separate concepts when it comes to supply chains, but for retailers, one cannot exist without the other. Therefore, if retailers are to make their supply chains more transparent, they must first be made more visible.

Implementing RFID technology can help provide retailers with unparalleled inventory tracking. By tracing stock at item-level from the factory to warehouse to shop floor, RFID can help retailers improve sustainable and ethical practices within their operations in the following ways:

Post-Purchase Care: By recording raw materials, RFID can assist retailers in tracking the origins of their products and enables them to have a longer life by tracing their composition and helping owners care for their items better.

Carbon Footprint Tracking: RFID technology can follow inventory at item-level at every step of their journey, allowing businesses to calculate the environmental impact of every individual product and correctly offset it.

Workload Easing: RFID also helps retailers ease the strain of workload within factories and distribution centres by taking the place of manual tasks such as stocktake and locating lost items.

Excess Inventory: Limiting the risk of waste products, RFID can help retailers monitor stock and manage future orders with these insights by distributing inventory to locations with high demand or designing a new collection whilst avoiding the features of underperforming products.

Manufacturing Conditions and Compliance: Tracking products back to their production source allows stakeholders to hold retailers accountable if the working conditions and practices of their internal and external factories are below standards.

Implementing Radical Change

Although organisational resistance to change is weakening, according to a recent survey by Accenture, 94% of experts said there is still no obvious effort to align the organisation’s culture with the goals of the change they intended to create. Yet the fact is, supply chains need to become radically more transparent, whether retail wants to embrace it or not.

The pandemic has exemplified change as an uncomfortable yet vital feature of business survival, and technology has been the great enabler for catalysing operational honesty and transparent reporting. But there is still much more to be done. End-to-end transparency is still a rarity, and retailers will need to push forward to experience the benefits of stakeholder satisfaction.

Book a consultation with Detego today to discover how RFID can help your organisation implement lasting and radical change through increased visibility.

Cloud-hosted RFID software

The digital supply chain

Detego’s RFID-based warehouse software enables retailers to automate and dramatically improve their receiving, picking/packing and shipping processes in factories and/or distribution centres. These steps are vital parts of an end-to-end RFID solution, providing full visibility across the entire supply chain.

Retail’s warehouse management systems are currently in a state of flux.

Supply chains are in crisis, consumer demands are unpredictably fluctuating, and labour shortages have reached historic heights – all disrupting the sector’s ability to fulfil even the basics of their supply and demand propositions.

Pair these challenges with the current e-commerce boom, and the result is a pivotal moment in time for the reinvention of retail logistics. In fact, investment in UK warehouses has already exceeded £6 billion this year, while the global warehouse automation market is expected to reach $30.99 billion by 2025.

Warehouses and distribution centres are undeniably the backbones of any retail operation, as departments that control the delivery of goods to consumers who — from their fingertips — expect accurate, timely, and efficient services regardless of what obstacles a retailer faces that week.

But to meet expectations, businesses must focus not just on sharpening their warehouse operations but also welcoming change and catalysing it into an opportunity for strategic innovation.

The Changing Models of Warehouses and Distribution Centers

Innovation within warehouse management is not just limited to improving tried and tested processes with technology. It is currently ripping up legacy systems as we know them and completely rethinking how the departments can be designed, fit for — post-pandemic — purpose.

Here we explore several new big-picture strategies that entirely remodel the way warehouses and distribution centres have traditionally functioned:

Micro-Warehousing

The tandem rise of e-commerce and consumer expectation for fast and efficient home delivery has inspired retailers to decentralise their once mammoth hubs and create physically segregated yet digitally connected operations through micro-warehousing.

Micro-warehouses and fulfilment centres allow retailers to house stock closer to their customer communities, enabling same-day delivery and click-and-collect services. They also help businesses optimise underutilised brick-and-mortar presences by repositioning them as dark stores — that exclusively cater to online purchases.

Distribution and Warehousing as a Service (DaaS, WaaS)

With companies facing new and unexpected obstacles every day, it’s no surprise the that B2B service market is booming. One of the latest propositions the retail sector is testing out is DaaS and WaaS.

Such services enable businesses to outsource these essential departments, radically shifting the strain of dealing with challenges like supply chain disruptions and labour shortages onto external partners who are better equipped to overcome such hurdles. Using WaaS and DaaS is a gamechanger for small and big businesses, assisting SMEs to manage quick growth without risking capital and helping large enterprises focus on other business activities without the distractions of logistical nightmares.

On-Demand Warehousing

With customer demand for goods straying away from typical timelines, businesses are increasingly unsure of how they will adapt to surging trends that follow no predetermined calendar. That is why on-demand warehouse services are becoming more popular.

On-demand warehouse platforms help retailers to find the perfect spaces for their immediate and short-term needs. This setup works with the fluidity of the global retail market, allowing companies to respond to rapid fluctuations, pilot stock with entirely new customer bases, and cater to unexpected peaks in demand – all while removing long-term and rigid contracts.

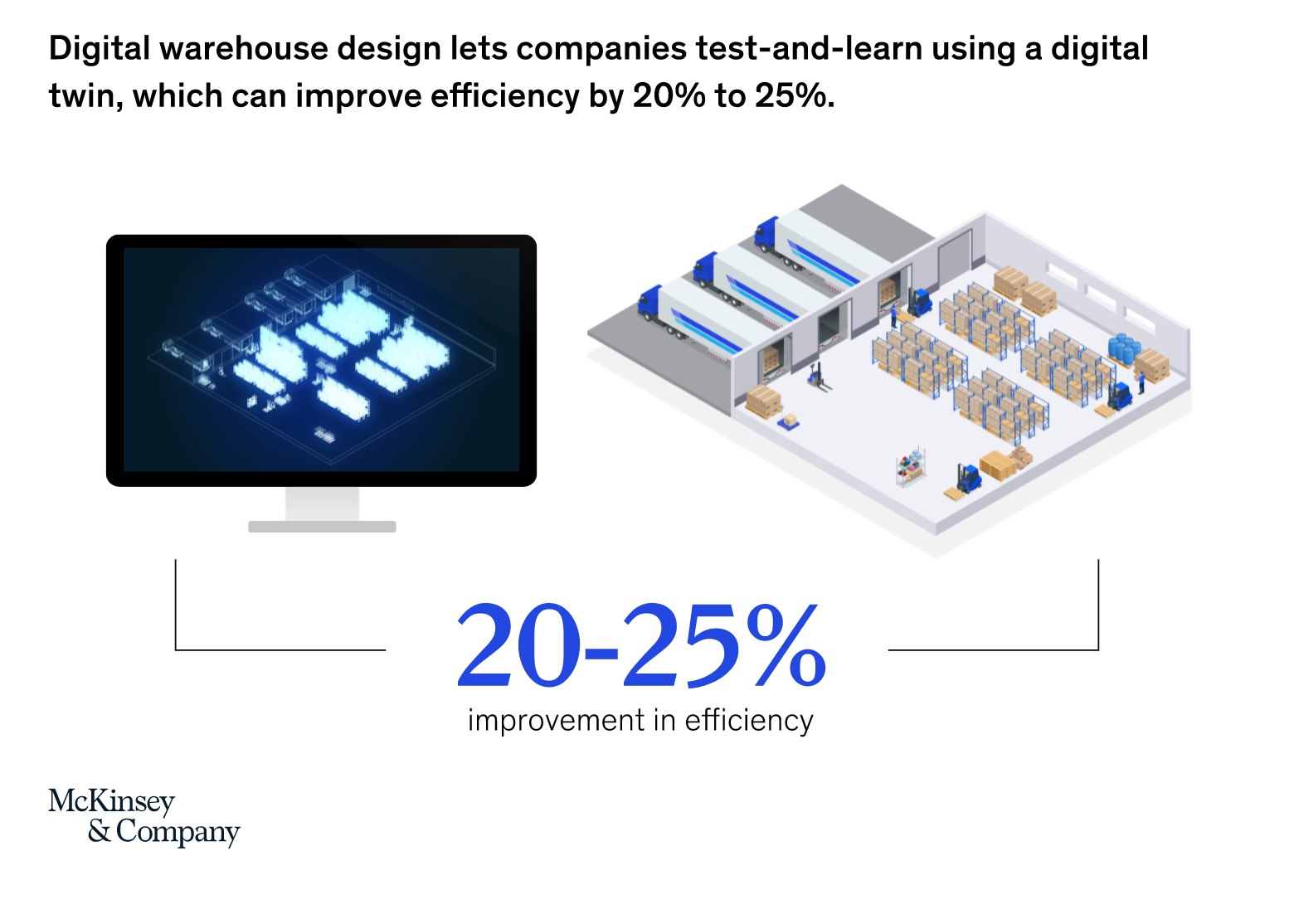

Digital Warehouse Twinning

If retail has learnt anything over the past 18 months, it’s that preparing for every unexpected eventuality is vital. That is why businesses are beginning to use technology to better their foresight.

Digital warehouse twinning is currently experiencing an uptick in use with retailers and is predicted to provide a 20%-25% uplift in efficiency. By building a digital twin of their warehouse, businesses can test new strategies and analyse the results of the operational changes they intend to make, all within a simulation. According to McKinsey & Company, this helps businesses make both big and small decisions — like floorplan redesigns and changes in workflow structures — without impacting the everyday functions of their warehouses.

The Future of Warehousing is Digital

Whether retailers intend to simply refine their existing warehouse processes or overhaul their models completely, it is no secret that digitisation will be embedded into the foundations of change.

Over the past 18 months, the adoption of technology has been essential for any business, helping them build agile, resilient, and responsive operations. And now, as retailers reflect upon their performance since the arrival of Covid-19, they’ve realised that quick decisions to implement innovation — once ideas born out of desperation — have grown in viability, becoming intrinsic to long-term strategies designed to help them succeed rather than just survive.

E-tailers like Amazon perfectly exemplify what it means to invest in cutting-edge innovation within warehouse operations whilst seeing a return on investment. For example, Amazon is known for their use of Autonomous Mobile Robots (AMR) to streamline logistics by picking and transporting stock without human supervision and integrating AI to predict inventory demand and help design floorplan navigations based on access needs. As a result, the industry leader in digital warehouse processes can deliver unapparelled levels of fulfilment across their global audiences.

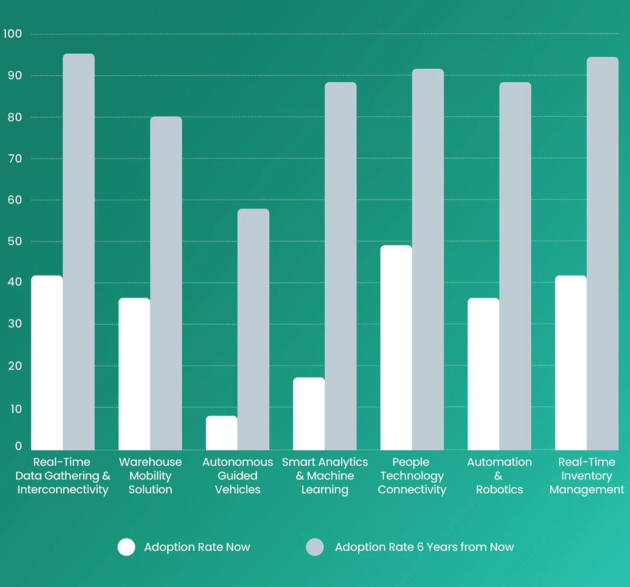

Taking a step back and looking at the retail sector as a whole, technology adoption within warehousing is set to soar over the next 6 years as these innovations evolve from being championed by evangelists into recognised processes with quantifiable results. Because according to the Harvard Business Review, there is plenty of room for improvement; 72% of companies believe their supply chain capabilities like warehousing and logistics to be digitally immature.

Technologies such as real-time data and inventory management are set to gain the most significant adoption rates in the next few years. And for good reason, the retail sector now knows that better stock visibility is necessary to make their activities intuitive to market volatility and shopper’s needs.

Why RFID is a One-Stop Solution for Operating a Warehouse with a Far-Reaching Impact

RFID technology provides real-time insights into inventory that currently helps retailers to solve many diverse challenges at once. Here we explore why integrating RFID into warehouses can allow businesses to achieve – what at first seem like wholly unconnected – business goals:

Creating Customer Loyalty

Building customer loyalty begins at the back-end of retail operations and not front-facing customer touchpoints. In fact, retail’s ramp-up of omnichannel – which has been firmly cemented as the go-to strategy for future success – has irreparably impacted how warehouses will need to function moving forward.

Delivering Fast Fulfilment through Product Transparency: When over 98% of shoppers claim delivery impacts their brand loyalty, shipping inaccuracies and delays are becoming a critical issue for retailers as demand for home delivery rises alongside e-commerce’s market takeover.

RFID’s ability to help businesses monitor inventory at item-level and in real-time means that product availability is becoming more accurate and automated as sales and returns are processed. As a result, companies can generate customer trust through the errorless communication of stock levels as they click-and-collect from stores and organise next-day delivery online.

Making Returns Easier with Shipping Accuracy: The rise of free returns policies has led to a mini-epidemic of high logistical costs and growing carbon emissions. In addition – according to the SOTI’S State of Mobility in Retail Report 2021 – over half of customers are unhappy with returns processes and want them made easier.

RFID reduces the risk of shipping mistakes by digitally automating the receipt of inbound goods to verify inventory and track individual stock pieces at every step of complex returns processes.

Reducing Costs and Optimising Efficiency

A rare new era of stagflation has arrived in the US and UK markets. Characterised by the inflation of prices, high unemployment – fuelled by “the great resignation” – and stagnant economic growth, industry experts, are wary of its long-term impact on the retail sector. As a result, retailers are becoming more cautious and considerate with every decision they make, hoping to reduce operational costs to keep prices low and demand high.

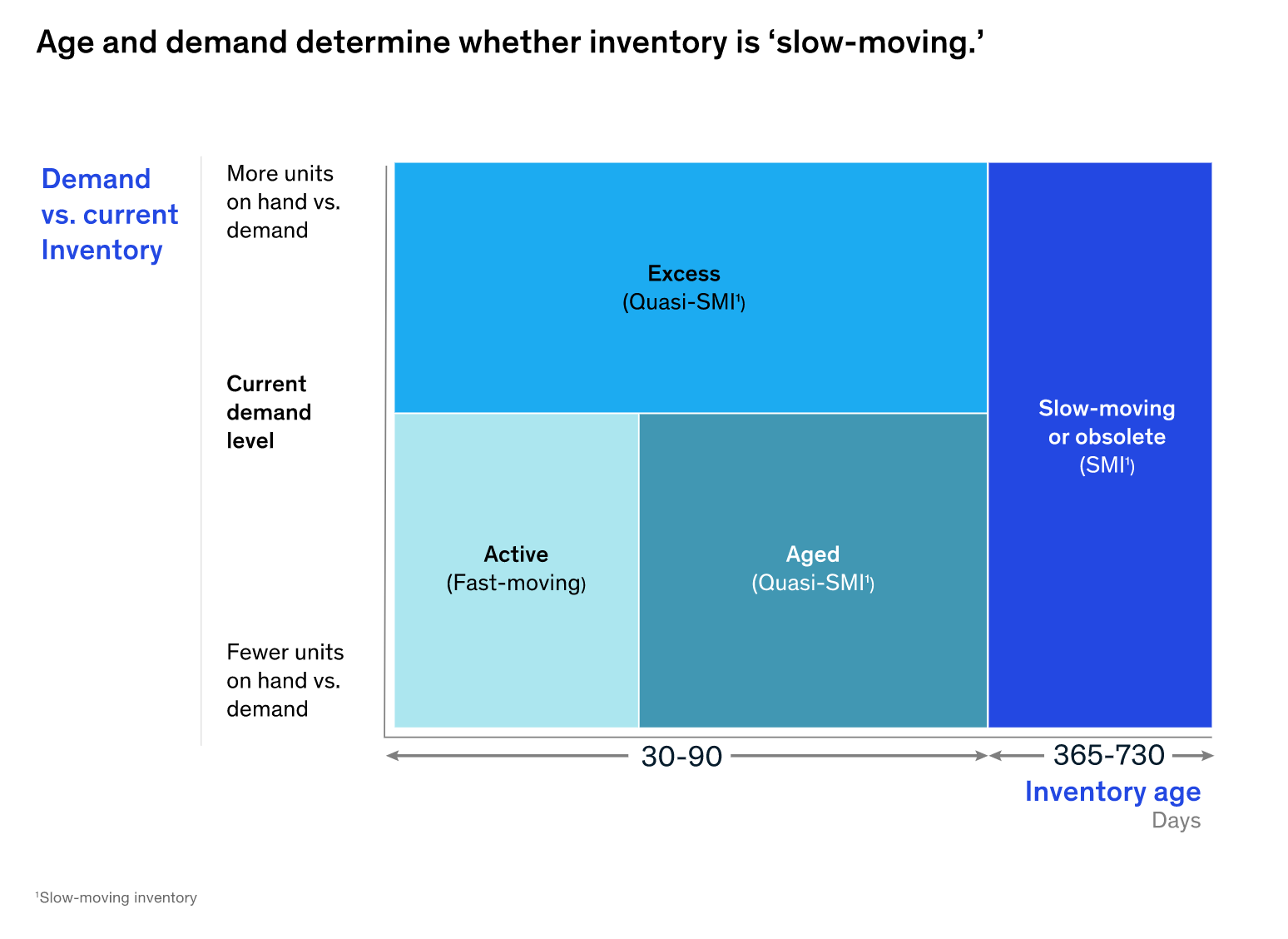

Managing Excess Stock through Inventory Protection: Slow-moving inventory has been a central problem for retail businesses, with the pandemic causing entire product categories such as evening-wear, holidays, and eating-out to become obsolete overnight. As a result, stagnating stock is a loss-leading problem that businesses are now beginning to tackle beyond outdated solutions such as seasonal sales, landfills and destruction.

RFID can help identify this stagnant inventory and trace its age and demand levels to inform how best to deal with stock in more sustainable ways. For example, the technology’s ability to trace individual goods back to manufacturers can additionally help to prove provenance as they enter resale markets.

Planning for the Future

Data is one of the most valuable assets a company can generate. It allows businesses to understand their customers on a granular level and trace what’s happening in their own ecosystems back to micro and macro market fluctuations. To plan more readily for the still unpredictable future, retailers are increasingly considering how to collect, connect and make sense of data to provide them with the best foresight.

Insights and Reporting through Label Printing: If businesses want to gain reliable and real-time insight into their logistics, they will need to imbed digital touchpoints into many of their existing processes. Warehouses present the perfect opportunity to create these touchpoints and track the inventory’s onward journey.

Quick and easy printing of RFID labels within warehouses can help enterprises with limited budgets to focus their intel-gathering on the journeys of specific stock. This can also enable smart shelving – a method of inventory visibility that allows retailers to trace customer engagement with stock as they pick it up and try it on. Insights generated this way help companies with everything from inventory planning to design development and visual merchandising.

Upskilling Workforces with easy RFID integration: The labour shortages that still plague the retail sector means that companies are becoming increasingly committed to investing in upskilling their workforce and providing them better tools to carry out everyday tasks.

Today, many RFID solutions are designed to work effortlessly with warehousing software, meaning the technology seamlessly fits into existing workflows without disruption. As a result, it helps make picking and packing less time consuming and laborious and increases employee’s ability to adapt to digital advancements with confidence and satisfaction.

Everything and Anything is Possible with Cloud Technology

Warehouses are the heart of any retail operation. As such, refining the processes within the walls of this department presents the opportunity to make widespread improvements across an entire business. Yet, so many of these advancements will be made possible by cloud technology.

Cloud technology allows different departments to automate inventory updates and access information in real-time, connecting workflows and injecting continuity into communication. Implementing cloud-based solutions into warehousing will provide retailers with the freedom of choice to radically change their models or merely update manual processes with digital.

Detego is a cutting-edge platform in the RFID space that delivers impact within their easily implemented cloud solutions. Book a consultation with Detego today to find out how they can help your business improve its warehouse and distribution centre practices and take the first steps towards implementing strategic innovation.

Cloud-hosted RFID software

Stock accuracy, on-floor availability, and omnichannel applications in stores.

Detego Store is a cloud-hosted RFID solution which digitises stock management processes, making them more efficient and more accurate. Implemented within hours, our multi-user app can provide intelligent stock takes and a smart in-store replenishment process. Later, you can scale the solution to offer omnichannel services and effectively manage your entire store operations with real-time, item-level inventory visibility and analytics.

Until recently, it has been relatively easy for consumers to take the smooth supply chains that serve them for granted.

But the pandemic’s continued impact on retail — generating tidal waves of disruptions — has demonstrated just how reliant contemporary customers are on frictionless and immediate delivery of goods.

In just the past three months, the retail sector has suffered the effects of everything from food shortages, factory fires, to torrential weather. All of which have pushed supply chains to breaking point and — for many experts — have been the worst disruptions they have ever witnessed.

Every day, there are news reports of global brands running out of stock, failing to open stores and delaying the delivery of products, subsequently impairing their ability to provide the immediate gratification customers have come to expect from their shopping experiences.

So as the start of the next financial year swiftly approaches, retailers have begun to set their sights on investment in supply chain solutions to navigate future problems — and for a good reason — these challenges have created speed bumps in economic recovery, and according to ING, supply chain issues are here to stay.

However, if retailers have learned anything from the past 18 months, it is that these problems are not in silos of specific geographical locations, sectors, or product categories. Instead, they are an interconnected global web of causes and effects that — at the start of 2020 — retail had primarily been unprepared for. But the industry now knows that to survive, they must embed these lessons into their operations, strategically and efficiently.

Future Supply Chains: From Outdated Systems to Innovative Digital Solutions

Research from 2018 found that visibility, fluctuating consumer demand, and inventory management were already some of the most concerning global supply chain issues.

So it comes as no surprise that the pandemic has not only exasperated these sizable problems, but it has exposed global supply chain operations as outdated processes that often create rather than remove points of immense friction.

But now, moving into a post-pandemic era, revisiting and adapting the legacy processes many supply chains operate upon will not be enough for retail’s survival. Instead, businesses within the sector must begin to consider the solutions confronting supply chain challenges in new and innovative ways designed to work in the world retailers are currently navigating.

Digitisation is central to how these kinds of solutions function, yet before Covid-19, only 15% of US retail businesses had entirely digitised their supply chain management processes, despite 60% of US retailers viewing supply chain digitisation as crucial. However, the acceleration of technology over the past 18 months has presented many opportunities for businesses to integrate these agile and efficient digital systems.

And as a result of the large number of technologies aiming to revolutionise the industry, the supply chain management market is estimated to reach USD 30.91 Billion by 2026.

Current Supply Chain Disruptions and their Emerging Solutions

Today, with supply chain disruptions varying in scope and scale, it is essential that before investments are made, retailers attempt to understand the impact of each problem at every stage of a product’s life cycle to decide upon the best solutions to invest in.

Here we explore the most significant supply chain challenges that retailers are currently and will continue to face alongside the innovative solutions helping to resolve them:

Unpredictable Customer Demands In an article just last month, we looked into the post-pandemic consumer and their unpredictable and ever-changing demands. Whilst uncertainty may be subsiding as the retail sector slowly recovers, consumer experts are still unsure of the long-term impact of the pandemic on customer sentiments. Yet, with retail supply chains hinging upon the fulfilment of customer needs, this uncertainty could cripple a businesses revenue.

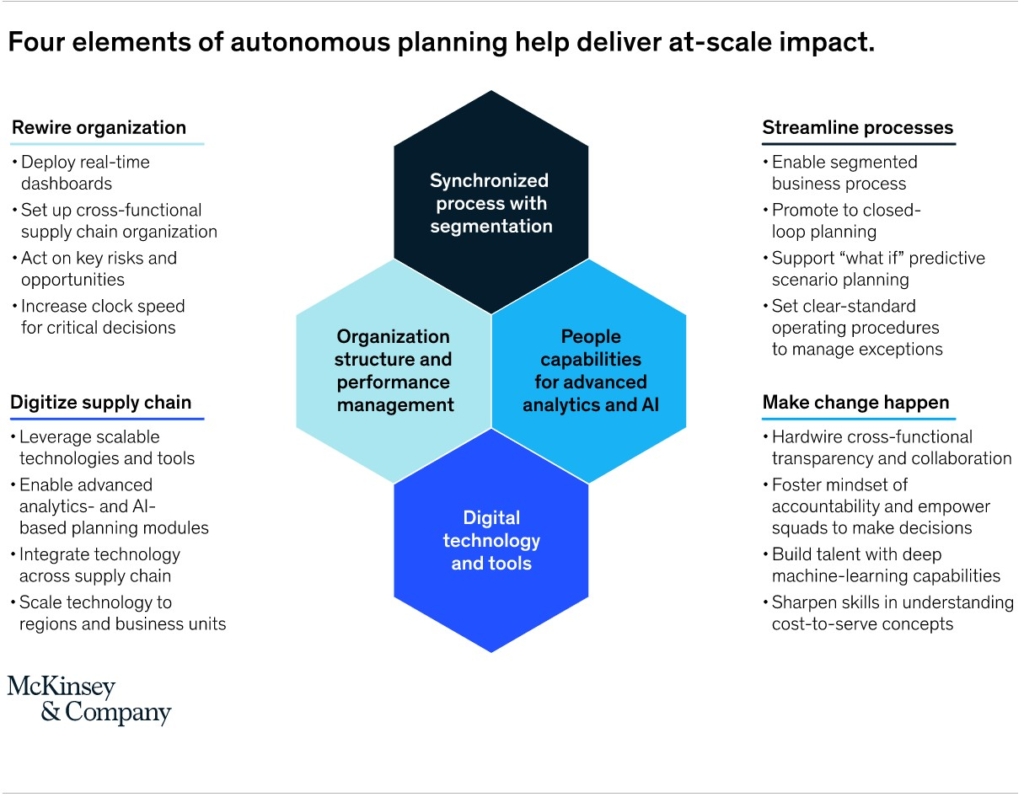

AI Forecasting: As AI-driven forecasting begins to mature, many businesses in the retail sector are finding themselves reliant on data-driven foresight to prepare for uncertain customer desires and mitigate the risk of history — as recent as early 2020 — repeating itself.

Shipping Delays

The blockage of a container ship in the Suez Canal in March this year, causing widespread delays worth an estimated $9.6bn of lost trade each day, illustrates how reliant supply chains are on tried and tested operations. Still today, air, sea and land distribution continue to struggle under the weight of these overwhelming market dictations, with retailers running the risk of paying for the storage of products with subsiding customer demand.

Lean Inventory: With no quick fix to shipping backlogs, an increasing number of retailers are broadening where they source their stock from and readdressing how they distribute their goods by exploring lean inventory processes. In this supply chain management method, companies attempt to reduce the waste they generate by lowering the volume of inventory and moving fulfilment closer to demand, ultimately scaling down their shipping needs and shortening lead times from factory to store. Overall, this strategy allows retailers to quickly respond to fluctuations in delivery times, recalibrate their logistics, and reduce the risk of money lost upfront.

Disjointed Workflows

As the nature of employed work becomes increasingly decentralised from offices, retail operations have had to quickly adapt their workflow processes to transfer information and efficiently facilitate teamwork throughout the supply chain. And technology has been a vital foundation for this shift towards the remote yet more connected working styles that have helped entire economies stay afloat over the past year and a half.

Cloud Software: In a recent survey, 83% of business executives say that their businesses now prioritise building and maintaining relationships with existing suppliers, and Cloud software has become integral to the management of these relationships. According to Accenture, “The cloud provides technologies that allow companies to process huge amounts of data—from virtually unlimited sources across the entire supply chain—at speeds and volumes never before possible.”

In practice, more immediate and precise communication between retailers and suppliers can speed up arduous back-and-forth processes such as quality control. Alongside this, the agile nature of the technology allows businesses to create digital continuity throughout entire product life cycles to make agile real-time decisions about goods at every stage.

Labour Shortages

The impact of furloughs, redundancies, and under-employment catalysed by the pandemic can still be felt today, as job vacancies continue to rise sharply — particularly in manufacturing and logistics. These workforce gaps have been detrimental to retail recovery, causing insufficiently staffed stores to shutter their doors and order fulfilment schedules to be derailed due to limited warehouse teams. However, these ongoing labour shortages have left retailers scratching their heads — and experts Unhappiness, skills gaps, and at home commitments are all cited as viable explanations.