Consumer mindsets are evolving at an accelerating pace.

While it wasn’t long ago that shoppers could be satisfied receiving the tiniest of details from a product’s journey before it came into their possession, years of unsustainable and unethical practices within retail supply chains have begun to tarnish the relationships between businesses and their customers.

Understandably, customers are increasingly demanding that the traditionally opaque supply chains that serve them are made more visible – and they’re using their wallets to back and promote these values. As a result, power has shifted, and unless retailers want to become obsolete, ignorance and dishonesty must be replaced with clarity and accountability.

Especially since — over the past 18 months — the pandemic has intensified this scrutiny, and it seems that now, for retailers to survive, they must relinquish their use of transparency as a novel marketing strategy and view it as a necessary process to be implemented into everything they do.

Transparency as a marketing tool is nothing new, businesses have been branding their performance as a method of storytelling that highlights their morality and pulls audiences in for a while now. Greenwashing, however, has become a concerning result of this trend, with companies picking and choosing what to report and positioning their activities in a positive light.

In fact, in the Business of Fashion’s and McKinsey & Company’s The State of Fashion 2020 report, almost 20% of executives claim that radical transparency is one of the top three themes impacting their business due to changing consumer desire for genuine and clear information.

What Does a Radically Transparent Supply Chain Look Like?

Radical transparency defines the complete disclosure of information at every link of a retailers supply chain. This includes everything from the sourcing of raw materials, water usage in textiles dying, factory working conditions, the environmental impact of goods distribution, and customer care instructions.

In the past few years, many organisations have led the charge regarding supply chain clarity. For example, in just the apparel sector exists Fashion revolution Eco-Age and Good on you – all of which currently hold fashion retailers accountable over the impact of their supply chains by taking different approaches to the promotion of reporting.

And reporting is the cornerstone of supply chain transparency, providing a window into the practice’s businesses abide by. H&M — leaders in supply chain transparency — are among many retailers who have aligned their manufacturing reporting with Transparency Pledge Reformation takes this a step further, making the environmental impact and traceability of their products public.

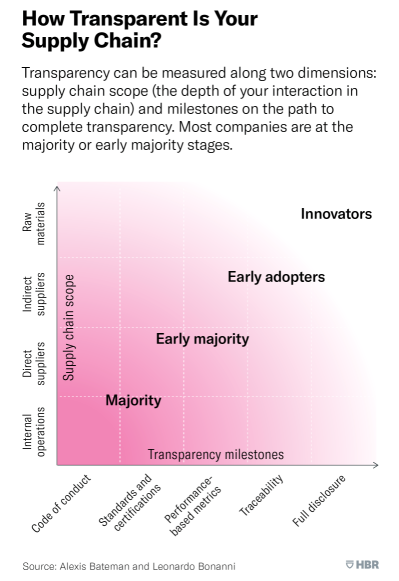

Yet, the widespread adoption of end-to-end supply chain clarity is limited and slow. While most businesses have begun to embed transparency into their internal operations and with direct suppliers, processes beyond their control – for the most part – remain opaque.

As a result, the companies that can trace their products’ raw materials are categorised as pioneers of supply chain transparency, whilst businesses that can track the activities of their indirect suppliers are ahead of the curve. Yet, for the majority of companies, moving towards full disclosure reporting can seem like an impossibly far milestone to reach. Nonetheless, it is one they must begin striving towards now.

Why Prioritise Transparency Now?

While many retailers readily look to improve their supply chain transparency, for many others, full-disclosure reporting is a practice being pressured upon them by both direct and indirect stakeholders. These different parties desire open and honest information for various reasons. Here we discuss the mindsets of these stakeholders and explore the reasons behind their demands for radical supply chain transparency:

1. Customers

The post-pandemic retail sector is filled with innovation that attracts the re-emerged consumer whose activism has been heightened by COVID-19. Multiple lockdowns had given the world time to re-evaluate its values, especially when last year, there was no good excuse to look away from societal issues that took the world stage, such as climate emergencies, poor factory conditions, and racial injustice. As a result, contemporary consumers are more scrutinising now than ever before and want the businesses they shop with to take accountability when problems within their internal operations are uncovered.

Sustainable and Ethical Practice:

It is arguably customers who drive retail’s interest for heightened clarity through their passion for advocating brands with sustainable products and ethical operations. In fact, 64% of shoppers look for ethical or sustainable features when making a purchase, and according to researchers at MIT Sloan School of Management, they may be willing to pay 2% to 10% more for products from companies that provide greater supply chain transparency.

In being able to see the impact of their purchases more clearly, customers are not only able to build trust with a retailer but become more assured that their own behaviours align with the values they hold.

Omnichannel:

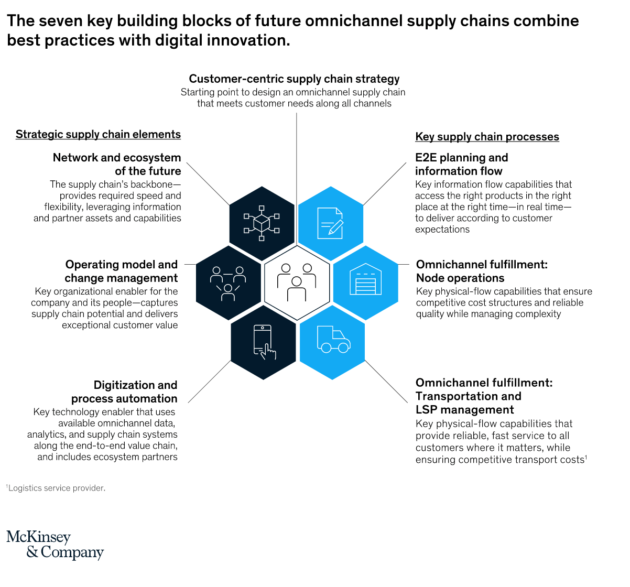

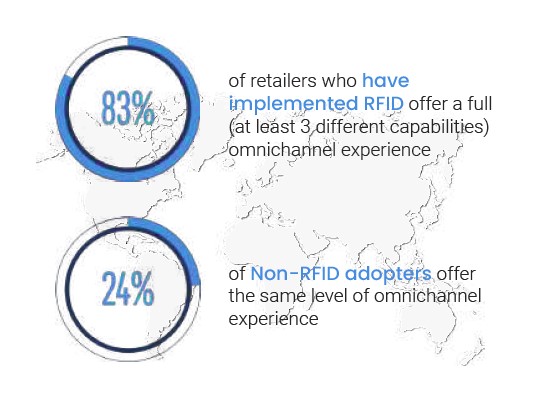

Customer-centricity is key to post-pandemic supply chain success as demand for goods becomes increasingly uncertain and erratically patterned. The growth of omnichannel means that shoppers expect retailers to cater to them at the physical and digital touchpoints they more fluidly move between in the wake of the pandemic.

By improving the transparency of their supply chains, retailers could much more readily provide the services created by the omnichannel shopping experience, such as real-time inventory visibility and same-day delivery fuelled by digitisation.

2. Employees

Employees are core stakeholders that the shift towards transparency would most impact. Making their working environments unambiguous and their everyday tasks clear to external audiences allows employees, customers and investors to hold retailers accountable in a public domain.

Welfare: According to Anti-Slavery International, there are 16 million people trapped in forced labour within the supply chains of businesses that supply our goods and services. Supply chain transparency is a small step to providing workers more protection over workplace conditions, wages, and personal agency, helping mitigate the risk of external suppliers taking advantage of labour in the sector.

As a result, by enhancing supply chain transparency, businesses are able to track the social impact of their operations and shine a light on grey areas within their own chains that they may not have complete control over.

3. Investors

Last year, Boohoo lost more than 1.5 billion euros in market value after it was uncovered that workers manufacturing their products earned less than minimum wage in poor working conditions. So making it clear that now more than ever, customers aligning their purchases with their values will have a tangible impact on revenue.

Return on Investment: For investors, the intrinsic link between supply chain controversy and loss in market value is a concerning risk. For example, violations in ESG practices were estimated to have erased almost half a trillion dollars’ worth of value from public companies from 2015 to 2019. ESG stands for environment, social and governance. All three domains increasingly feed into an investors decision to back a company beyond financial projections.

So, with investors progressively looking to work with businesses that have a positive impact, transparency is a firm method of proving compliance with every step of the EGS chain that can easily be mapped to the supply chain.

Transparency and Visibility: One Cannot Exist Without the Other

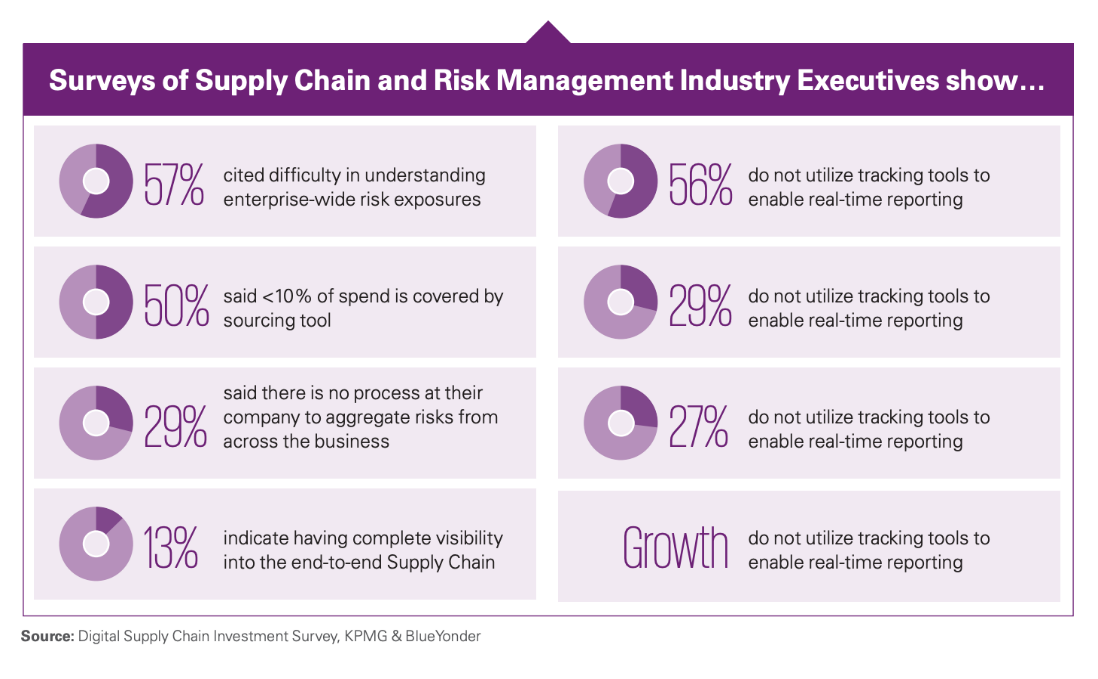

Now that we have made a case for supply chain transparency, there is still the question of how these typically tangled and murky operations can become crystal clear when only 13% of retail executives currently describe having end-to-end visibility.

Although often and mistakenly interchanged for one another, transparency and visibility are two separate concepts when it comes to supply chains, but for retailers, one cannot exist without the other. Therefore, if retailers are to make their supply chains more transparent, they must first be made more visible.

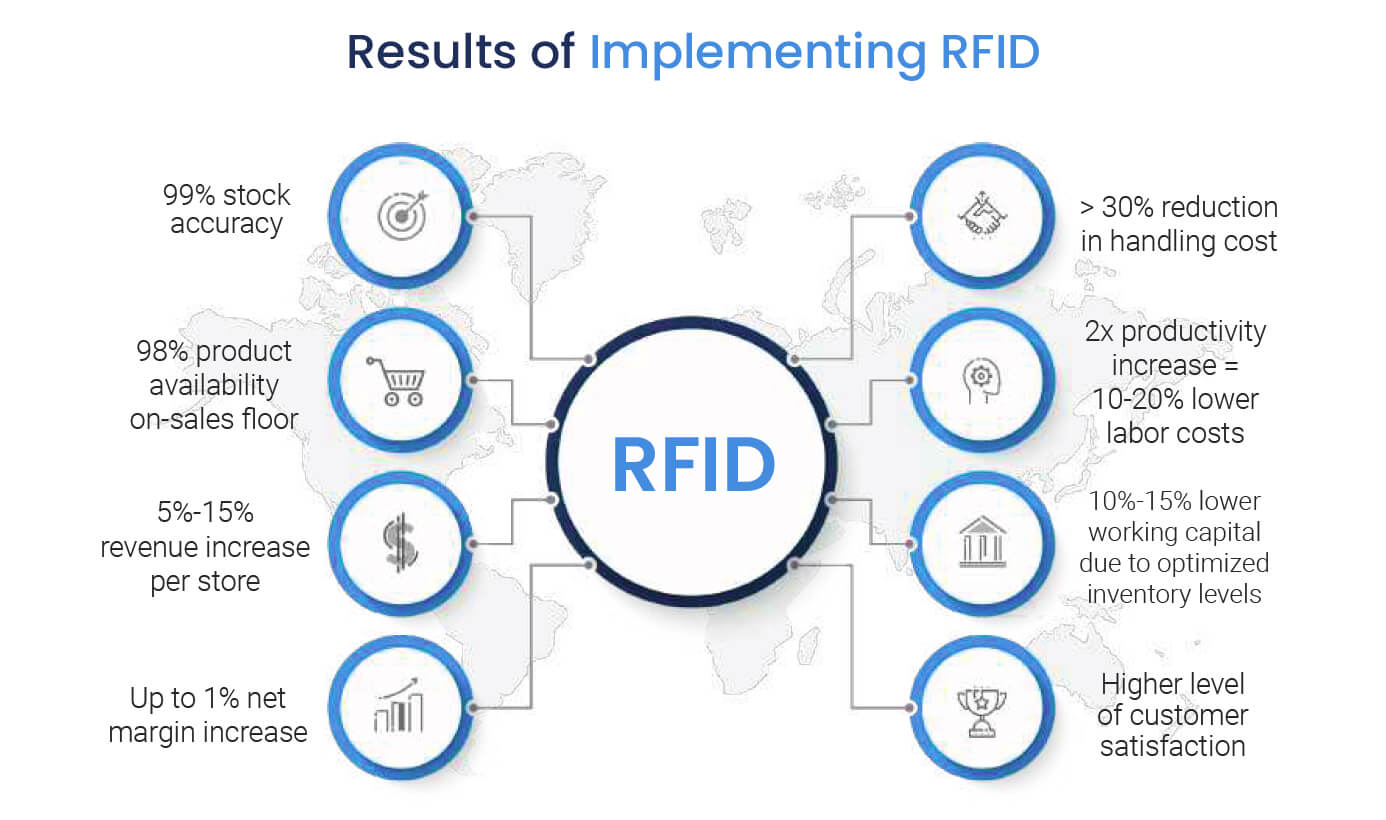

Implementing RFID technology can help provide retailers with unparalleled inventory tracking. By tracing stock at item-level from the factory to warehouse to shop floor, RFID can help retailers improve sustainable and ethical practices within their operations in the following ways:

Post-Purchase Care: By recording raw materials, RFID can assist retailers in tracking the origins of their products and enables them to have a longer life by tracing their composition and helping owners care for their items better.

Carbon Footprint Tracking: RFID technology can follow inventory at item-level at every step of their journey, allowing businesses to calculate the environmental impact of every individual product and correctly offset it.

Workload Easing: RFID also helps retailers ease the strain of workload within factories and distribution centres by taking the place of manual tasks such as stocktake and locating lost items.

Excess Inventory: Limiting the risk of waste products, RFID can help retailers monitor stock and manage future orders with these insights by distributing inventory to locations with high demand or designing a new collection whilst avoiding the features of underperforming products.

Manufacturing Conditions and Compliance: Tracking products back to their production source allows stakeholders to hold retailers accountable if the working conditions and practices of their internal and external factories are below standards.

Implementing Radical Change

Although organisational resistance to change is weakening, according to a recent survey by Accenture, 94% of experts said there is still no obvious effort to align the organisation’s culture with the goals of the change they intended to create. Yet the fact is, supply chains need to become radically more transparent, whether retail wants to embrace it or not.

The pandemic has exemplified change as an uncomfortable yet vital feature of business survival, and technology has been the great enabler for catalysing operational honesty and transparent reporting. But there is still much more to be done. End-to-end transparency is still a rarity, and retailers will need to push forward to experience the benefits of stakeholder satisfaction.

Book a consultation with Detego today to discover how RFID can help your organisation implement lasting and radical change through increased visibility.

Cloud-hosted RFID software

The digital supply chain

Detego’s RFID-based warehouse software enables retailers to automate and dramatically improve their receiving, picking/packing and shipping processes in factories and/or distribution centres. These steps are vital parts of an end-to-end RFID solution, providing full visibility across the entire supply chain.

Retail’s warehouse management systems are currently in a state of flux.

Supply chains are in crisis, consumer demands are unpredictably fluctuating, and labour shortages have reached historic heights – all disrupting the sector’s ability to fulfil even the basics of their supply and demand propositions.

Pair these challenges with the current e-commerce boom, and the result is a pivotal moment in time for the reinvention of retail logistics. In fact, investment in UK warehouses has already exceeded £6 billion this year, while the global warehouse automation market is expected to reach $30.99 billion by 2025.

Warehouses and distribution centres are undeniably the backbones of any retail operation, as departments that control the delivery of goods to consumers who — from their fingertips — expect accurate, timely, and efficient services regardless of what obstacles a retailer faces that week.

But to meet expectations, businesses must focus not just on sharpening their warehouse operations but also welcoming change and catalysing it into an opportunity for strategic innovation.

The Changing Models of Warehouses and Distribution Centers

Innovation within warehouse management is not just limited to improving tried and tested processes with technology. It is currently ripping up legacy systems as we know them and completely rethinking how the departments can be designed, fit for — post-pandemic — purpose.

Here we explore several new big-picture strategies that entirely remodel the way warehouses and distribution centres have traditionally functioned:

Micro-Warehousing

The tandem rise of e-commerce and consumer expectation for fast and efficient home delivery has inspired retailers to decentralise their once mammoth hubs and create physically segregated yet digitally connected operations through micro-warehousing.

Micro-warehouses and fulfilment centres allow retailers to house stock closer to their customer communities, enabling same-day delivery and click-and-collect services. They also help businesses optimise underutilised brick-and-mortar presences by repositioning them as dark stores — that exclusively cater to online purchases.

Distribution and Warehousing as a Service (DaaS, WaaS)

With companies facing new and unexpected obstacles every day, it’s no surprise the that B2B service market is booming. One of the latest propositions the retail sector is testing out is DaaS and WaaS.

Such services enable businesses to outsource these essential departments, radically shifting the strain of dealing with challenges like supply chain disruptions and labour shortages onto external partners who are better equipped to overcome such hurdles. Using WaaS and DaaS is a gamechanger for small and big businesses, assisting SMEs to manage quick growth without risking capital and helping large enterprises focus on other business activities without the distractions of logistical nightmares.

On-Demand Warehousing

With customer demand for goods straying away from typical timelines, businesses are increasingly unsure of how they will adapt to surging trends that follow no predetermined calendar. That is why on-demand warehouse services are becoming more popular.

On-demand warehouse platforms help retailers to find the perfect spaces for their immediate and short-term needs. This setup works with the fluidity of the global retail market, allowing companies to respond to rapid fluctuations, pilot stock with entirely new customer bases, and cater to unexpected peaks in demand – all while removing long-term and rigid contracts.

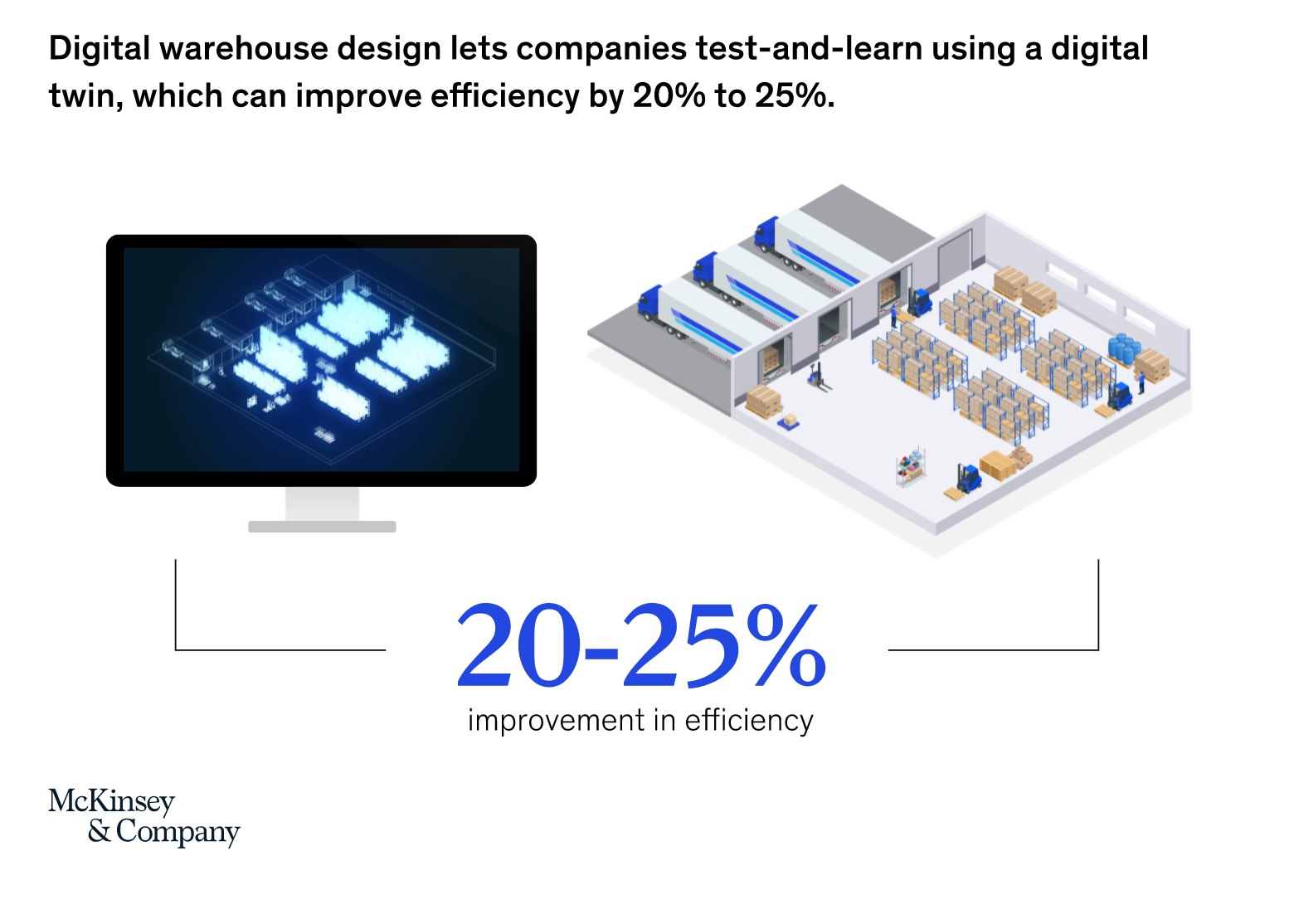

Digital Warehouse Twinning

If retail has learnt anything over the past 18 months, it’s that preparing for every unexpected eventuality is vital. That is why businesses are beginning to use technology to better their foresight.

Digital warehouse twinning is currently experiencing an uptick in use with retailers and is predicted to provide a 20%-25% uplift in efficiency. By building a digital twin of their warehouse, businesses can test new strategies and analyse the results of the operational changes they intend to make, all within a simulation. According to McKinsey & Company, this helps businesses make both big and small decisions — like floorplan redesigns and changes in workflow structures — without impacting the everyday functions of their warehouses.

The Future of Warehousing is Digital

Whether retailers intend to simply refine their existing warehouse processes or overhaul their models completely, it is no secret that digitisation will be embedded into the foundations of change.

Over the past 18 months, the adoption of technology has been essential for any business, helping them build agile, resilient, and responsive operations. And now, as retailers reflect upon their performance since the arrival of Covid-19, they’ve realised that quick decisions to implement innovation — once ideas born out of desperation — have grown in viability, becoming intrinsic to long-term strategies designed to help them succeed rather than just survive.

E-tailers like Amazon perfectly exemplify what it means to invest in cutting-edge innovation within warehouse operations whilst seeing a return on investment. For example, Amazon is known for their use of Autonomous Mobile Robots (AMR) to streamline logistics by picking and transporting stock without human supervision and integrating AI to predict inventory demand and help design floorplan navigations based on access needs. As a result, the industry leader in digital warehouse processes can deliver unapparelled levels of fulfilment across their global audiences.

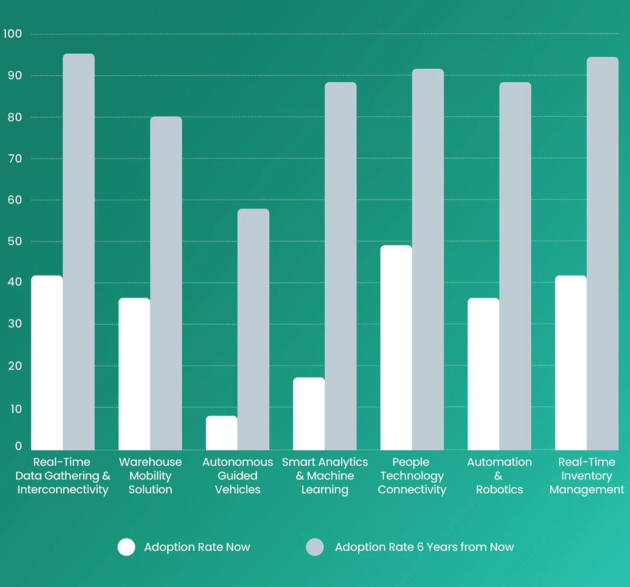

Taking a step back and looking at the retail sector as a whole, technology adoption within warehousing is set to soar over the next 6 years as these innovations evolve from being championed by evangelists into recognised processes with quantifiable results. Because according to the Harvard Business Review, there is plenty of room for improvement; 72% of companies believe their supply chain capabilities like warehousing and logistics to be digitally immature.

Technologies such as real-time data and inventory management are set to gain the most significant adoption rates in the next few years. And for good reason, the retail sector now knows that better stock visibility is necessary to make their activities intuitive to market volatility and shopper’s needs.

Why RFID is a One-Stop Solution for Operating a Warehouse with a Far-Reaching Impact

RFID technology provides real-time insights into inventory that currently helps retailers to solve many diverse challenges at once. Here we explore why integrating RFID into warehouses can allow businesses to achieve – what at first seem like wholly unconnected – business goals:

Creating Customer Loyalty

Building customer loyalty begins at the back-end of retail operations and not front-facing customer touchpoints. In fact, retail’s ramp-up of omnichannel – which has been firmly cemented as the go-to strategy for future success – has irreparably impacted how warehouses will need to function moving forward.

Delivering Fast Fulfilment through Product Transparency: When over 98% of shoppers claim delivery impacts their brand loyalty, shipping inaccuracies and delays are becoming a critical issue for retailers as demand for home delivery rises alongside e-commerce’s market takeover.

RFID’s ability to help businesses monitor inventory at item-level and in real-time means that product availability is becoming more accurate and automated as sales and returns are processed. As a result, companies can generate customer trust through the errorless communication of stock levels as they click-and-collect from stores and organise next-day delivery online.

Making Returns Easier with Shipping Accuracy: The rise of free returns policies has led to a mini-epidemic of high logistical costs and growing carbon emissions. In addition – according to the SOTI’S State of Mobility in Retail Report 2021 – over half of customers are unhappy with returns processes and want them made easier.

RFID reduces the risk of shipping mistakes by digitally automating the receipt of inbound goods to verify inventory and track individual stock pieces at every step of complex returns processes.

Reducing Costs and Optimising Efficiency

A rare new era of stagflation has arrived in the US and UK markets. Characterised by the inflation of prices, high unemployment – fuelled by “the great resignation” – and stagnant economic growth, industry experts, are wary of its long-term impact on the retail sector. As a result, retailers are becoming more cautious and considerate with every decision they make, hoping to reduce operational costs to keep prices low and demand high.

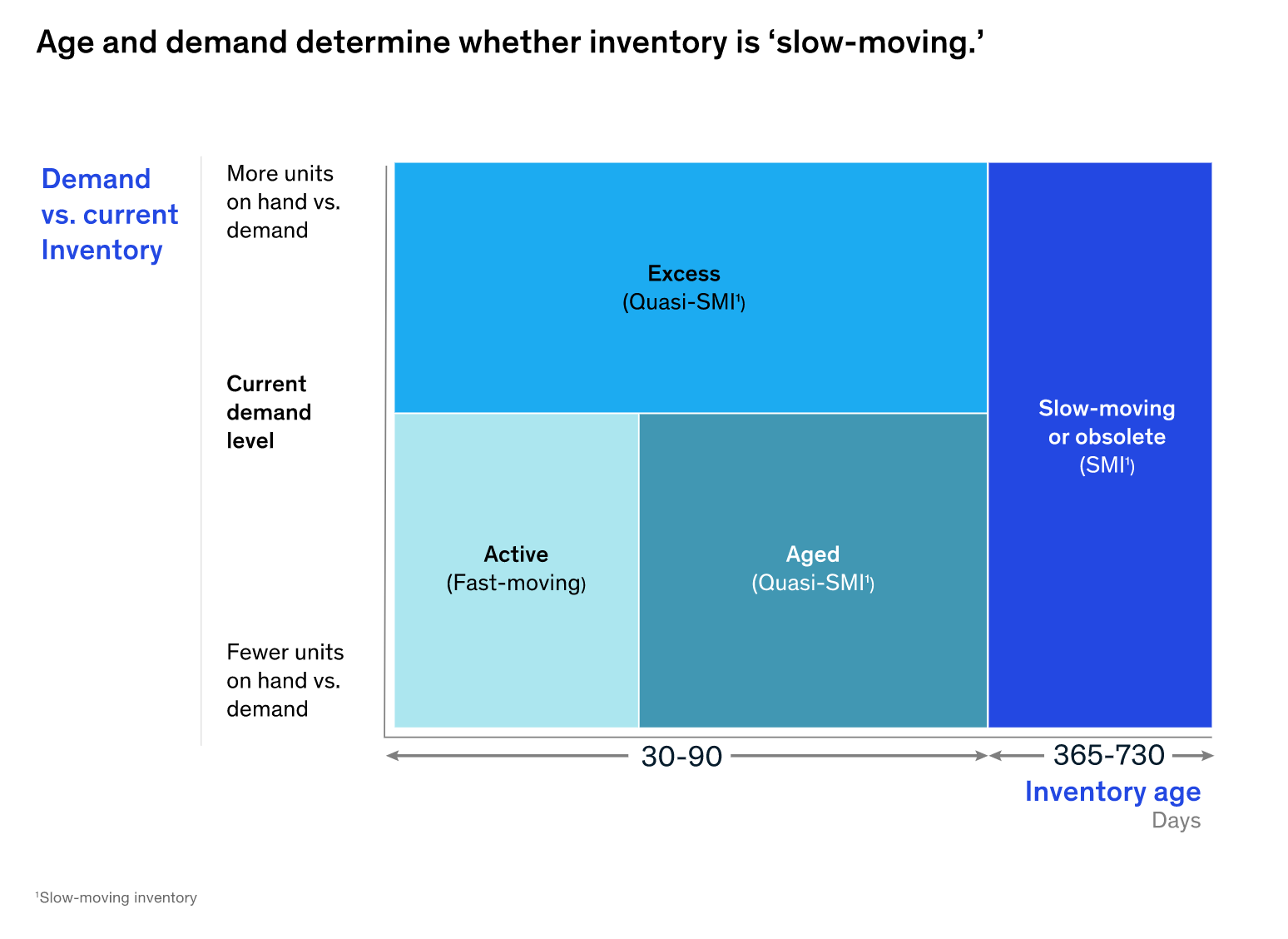

Managing Excess Stock through Inventory Protection: Slow-moving inventory has been a central problem for retail businesses, with the pandemic causing entire product categories such as evening-wear, holidays, and eating-out to become obsolete overnight. As a result, stagnating stock is a loss-leading problem that businesses are now beginning to tackle beyond outdated solutions such as seasonal sales, landfills and destruction.

RFID can help identify this stagnant inventory and trace its age and demand levels to inform how best to deal with stock in more sustainable ways. For example, the technology’s ability to trace individual goods back to manufacturers can additionally help to prove provenance as they enter resale markets.

Planning for the Future

Data is one of the most valuable assets a company can generate. It allows businesses to understand their customers on a granular level and trace what’s happening in their own ecosystems back to micro and macro market fluctuations. To plan more readily for the still unpredictable future, retailers are increasingly considering how to collect, connect and make sense of data to provide them with the best foresight.

Insights and Reporting through Label Printing: If businesses want to gain reliable and real-time insight into their logistics, they will need to imbed digital touchpoints into many of their existing processes. Warehouses present the perfect opportunity to create these touchpoints and track the inventory’s onward journey.

Quick and easy printing of RFID labels within warehouses can help enterprises with limited budgets to focus their intel-gathering on the journeys of specific stock. This can also enable smart shelving – a method of inventory visibility that allows retailers to trace customer engagement with stock as they pick it up and try it on. Insights generated this way help companies with everything from inventory planning to design development and visual merchandising.

Upskilling Workforces with easy RFID integration: The labour shortages that still plague the retail sector means that companies are becoming increasingly committed to investing in upskilling their workforce and providing them better tools to carry out everyday tasks.

Today, many RFID solutions are designed to work effortlessly with warehousing software, meaning the technology seamlessly fits into existing workflows without disruption. As a result, it helps make picking and packing less time consuming and laborious and increases employee’s ability to adapt to digital advancements with confidence and satisfaction.

Everything and Anything is Possible with Cloud Technology

Warehouses are the heart of any retail operation. As such, refining the processes within the walls of this department presents the opportunity to make widespread improvements across an entire business. Yet, so many of these advancements will be made possible by cloud technology.

Cloud technology allows different departments to automate inventory updates and access information in real-time, connecting workflows and injecting continuity into communication. Implementing cloud-based solutions into warehousing will provide retailers with the freedom of choice to radically change their models or merely update manual processes with digital.

Detego is a cutting-edge platform in the RFID space that delivers impact within their easily implemented cloud solutions. Book a consultation with Detego today to find out how they can help your business improve its warehouse and distribution centre practices and take the first steps towards implementing strategic innovation.

Cloud-hosted RFID software

Stock accuracy, on-floor availability, and omnichannel applications in stores.

Detego Store is a cloud-hosted RFID solution which digitises stock management processes, making them more efficient and more accurate. Implemented within hours, our multi-user app can provide intelligent stock takes and a smart in-store replenishment process. Later, you can scale the solution to offer omnichannel services and effectively manage your entire store operations with real-time, item-level inventory visibility and analytics.

It is no exaggeration to say that retail has changed like never before.

For some time, operations have been growing increasingly more complex, and shoppers increasingly more discerning. Now that evolution has been accelerated. Retailers must be flexible in meeting consumer demands in the face of a rapidly changing retail landscape if they hope to succeed.

As the industry recovers, retailers pursuing digital transformation in order to optimize operations, expand omnichannel fulfilment, and enable data-driven decisions are poised to lead the way. One of the foundational technologies providing insight to drive digital transformation? RFID.

Detego has been working with Geis group, the German logistics specialists, for over 7 years. Gies serves a variety of companies and retailers as a dedicated transport and distribution partner, covering the healthcare, automobile, and retail industries, to name a few. Hans Geis takes great pride in delivering specific software and system solutions tailored to the needs of their customers.

One of Geis group’s customers, the fashion retailer Drykorn, has a particularly high volume of products to process and distribute – with over 700,000 items processed in just 3 months.

Because of this high order volume, and because Drykorn already uses RFID tags on their products – it was the perfect opportunity for Geis to leverage the technology within their logistics centres.

Download the case study to find out how Detego delivered a solution that would deliver long term success:

“Working with Detego has enabled us to achieve significant process optimizations in the areas of incoming and outgoing goods over the past few years.”

Marius Kraft, Project Manager, Geis Group

Beauty retail is an industry at a crossroads. A sector resilient to crisis and change compared to other retail categories, cosmetic brands are beginning to feel the effects of the pandemic and ongoing industry changes.

In recent years, apparel and sports retailers have undergone digital transformations to stay competitive, and now beauty brands have an opportunity to follow suit. Read this eBook to discover how and why beauty retailing is set to transform into the industry of the future.

Beauty retail: An industry at a Crossroads

The apparel and sports retail industry have undergone mass change over recent years. Such retailers have undertaken digital transformation journeys in their store and distribution networks to adapt to digital-first customers and eCommerce competition. The beauty sector, however, is still behind the curve.

In most major beauty-industry markets, in-store shopping accounted for up to 85 per cent of beauty product purchases before the COVID-19 crisis – (McKinsey&Co) making the level of eCommerce penetration lower than in other retail sectors. While retailers in other categories have been forced to innovate and adapt in the face of falling brick-and-mortar sales, competition from eCommerce and direct-to-consumer models, brick-and-mortar beauty sales were more resilient.

But this is changing. Not only are eCommerce levels steadily increasing year-on-year, but the COVID-19 pandemic has accelerated this drastically, driving five years of change in a single year, according to

IBM. This leaves brick-and-mortar beauty retailers on unsteady ground. Beyond this, brands will have to navigate a more digital-centric environment and optimise margins to cope with reduced sales.

The good news is many of the challenges that are now facing beauty have been facing apparel or CPG for years. The digital solutions and strategies that have allowed apparel to adapt are well established and ready to deploy to the sector. The digital transformations that many apparel and sports retailers were forced to undergo will not only fit beauty retailers but will also help them solve older challenges. Beauty retailers may need to go on a similar journey to apparel, but the tracks are there to follow.

What is in the eBook?

- Beauty retailing at a crossroads

- Bringing beauty operations up-to-speed

- Accuracy redefining margins

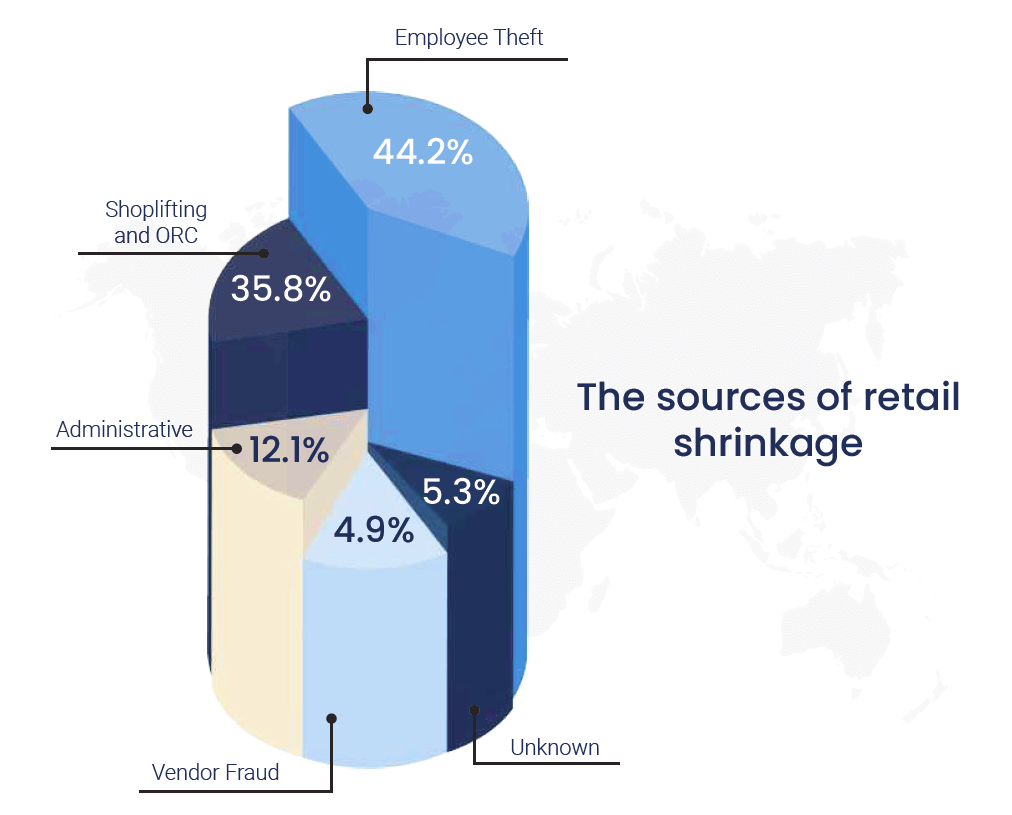

- Fixing beauty’s shrinkage problem

- Catching up with the omnichannel trend

- Countering the Gray Market

- Becoming digital and analytics leaders

Discover how retail RFID is changing the industry for good. This eBook will guide you through the top 10 needs identified by retailers to ensure sustainable success in the modern environment. Explore the common challenges preventing retailers from achieving their goals and learn how applying smart RFID-based solutions delivers consistently good results.

What is in the eBook?

The retail industry is currently ruled by change. The digital age has seen a huge growth in competition from e-commerce and a rapid shift in consumer preferences. This shift has altered the industry greatly with modern ‘omnichannel’ customers demanding to shop where they want, how they want and when they want. Delivering such an experience is a challenge, one that requires brick-and-mortar retailers to change.

In this eBook, we analyse the top 10 needs identified by retailers to ensure sustainable success in the modern environment. Within each of these needs, we identify the challenges often preventing retailers from achieving them, and how applying smart RFID-based solutions can deliver consistently good results.

Improving key metrics in stores

- How retailers use RFID for quick and efficient stocktakes and cycle counts

- Improving stock accuracy in stores

- How smart solutions are being put to use for item-level replenishment, ensuring products and sizes are always available to be sold.

Delivering to customers with retail RFID

- How stores can reduce common customer friction points

- The relationship between RFID and effective omnichannel services

- The advanced retail RFID solutions that improve the in-store customer experience like chatbots and smart fitting rooms.

Optimising supply chains from source to store with automated processes

- How to achieve supply chain visibility with real-time info on the movement of products inside and across individual stores and distribution stages.

- How RFID is used to aid logistics at distribution centres, including automated processes like exception handling and order picking.

- What RFID means for retailers’ data and analytics capabilities, such as advanced supply chain traceability and new KPIs for stores and DC’s.

Protecting brands and products from theft, counterfeits and the grey market.

- How RFID can be used to monitor and reduce shrinkage, including theft, both in stores and across the entire supply chain.

- How brands are combatting counterfeit goods by tagging and tracing their products with RFID.

- What the Grey Market means for retail and how several major brands use RFID traceability to locate and stop the source of grey market products.

Overview

Detego has installed its cloud-hosted RFID (Radio Frequency Identification) SaaS platform in Marc Cain’s new state-of-the-art Distribution Centre (DC). Detego delivered the solution alongside KNAPP, who led the overall development of the new centralised operation. The highly-automated Distribution Centre, based in Germany, uses RFID tunnels to verify inbound and outbound shipments without needing to open any boxes. The implementation of RFID in the Distribution Centre allows for over 35,000 articles to be processed on a daily basis, with 100% accuracy and significant improvement to efficiency and visibility of the supply chain.

The Challenge

Due to high demand online and in-store, Marc Cain decided to centralise their 6 regional warehouses into a single cutting-edge distribution centre, reinforced with the right technology to handle the high frequency of orders.

The solution

KNAPP AG led the design of the highly automated DC and they brought in Detego to implement an RFID solution – they needed to be able to efficiently validate shipments in and out of the DC with the efficiency and complete accuracy only possible with RFID

The Result

Utilising the Detego platform, Marc Cain’s DC verifies all inbound and outbound orders on an item-level without needing to open boxes. Staff simply place orders on the conveyor, and they pass through an RFID tunnel, which validates every item in the carton in seconds. Alongside highly sophisticated storage and packing processes implemented by KNAPP, the solution allows for 35,000 articles to be processed in a single day, with 100% accuracy.

Building a DC fit for the future

Marc Cain is a worldwide premium brand for women’s fashion, operating predominantly out of Germany. After continued growth, the brand opted to move away from their regional warehouses to develop and construct a highly-sophisticated singular DC which boasts over 24,500m2 of usable area. Marc Cain’s logistics and solutions partner, KNAPP, brought in RFID specialists, Detego, to integrate the necessary RFID systems with their leading KiSoft WMS & WCS software. Doing so allows for automated item-level tracking of products both entering and leaving the Distribution Centre. These advancements have enabled Marc Cain to cope with their increased demand whilst ensuring complete accuracy and timely shipping of all orders.

“As we had already experienced good cooperation in another project with Detego, we have reached out to them when we started discussing the RFID request Marc Cain was looking for. Within a short time, we were able to integrate the state-of-the art platform from Detego in the solution we were providing to Marc Cain. With that extension, we can support Marc Cain to increase the efficiency and reliability inside the warehouse and have 100% content checks for every delivery leaving the warehouse”

Stefan Leichtenmueller – Customer Care Manager.

Automated RFID validation for complete accuracy

RFID is frequently being adopted in Apparel retailers’ Distribution Centres, as the speed at which it can process shipments at item-level is unmatched. Detego has a strong pedigree of deploying RFID solutions in the supply chain, being the first to develop an end-to-end software platform for retail. This experience, alongside their focus on the apparel retail sector, makes their advanced RFID platform a perfect match for KNAPPs leading warehouse automation systems and software for e-commerce, retail, and fashion. The decision to use RFID was made even more attractive by the fact Marc Cain have already adopted RFID-driven processes in stores, allowing them to gain additional value out of their digital garments within the supply chain.

“With this solution, Marc Cain can perform automated inbound and outbound RFID validation, ensuring complete accuracy going in and out of the Distribution Centre,”

Urs Konstantin Rouette, Managing Director, Technical Development, Production, Purchase & Logistics.

Staff simply place cartons on a conveyor and the boxes are taken through an RFID tunnel which counts and validates every individual garment inside the box, without needing a line of sight. All information is stored in the cloud-hosted Detego platform providing complete visibility over items entering and leaving the DC. Any cartons with discrepancies are automatically diverted to exception handling lanes where they are double-checked with High-Density Read Chambers (HDRCs) and subsequently corrected.

KNAPP also share additional customers with Detego and is one of many 3rd party logistics providers that Detego has recently partnered with to integrate their RFID platform. As the demand for visibility and operational efficiencies in the supply chain increase, more retailers are seeking RFID systems to complement their existing technology stacks from factory, to distribution centre and throughout store networks.

Take a look around the DC with project leaders, KNAPP:

Want the latest retail and retail tech insights directly to your inbox?

Managing the flow of merchandise in retail supply chains has always been a challenge.

Traditionally, the large quantities being dealt with meant that visibility of merchandise was poor. Items were tracked and accounted for in rough quantities, not consistently or accurately enough to hold suppliers and distribution centres accountable for mistakes and inaccuracies. This meant a fair amount of leakage, either of efficiency or directly in the form of physical shrinkage as items become ‘lost’, damaged or shipped incorrectly.

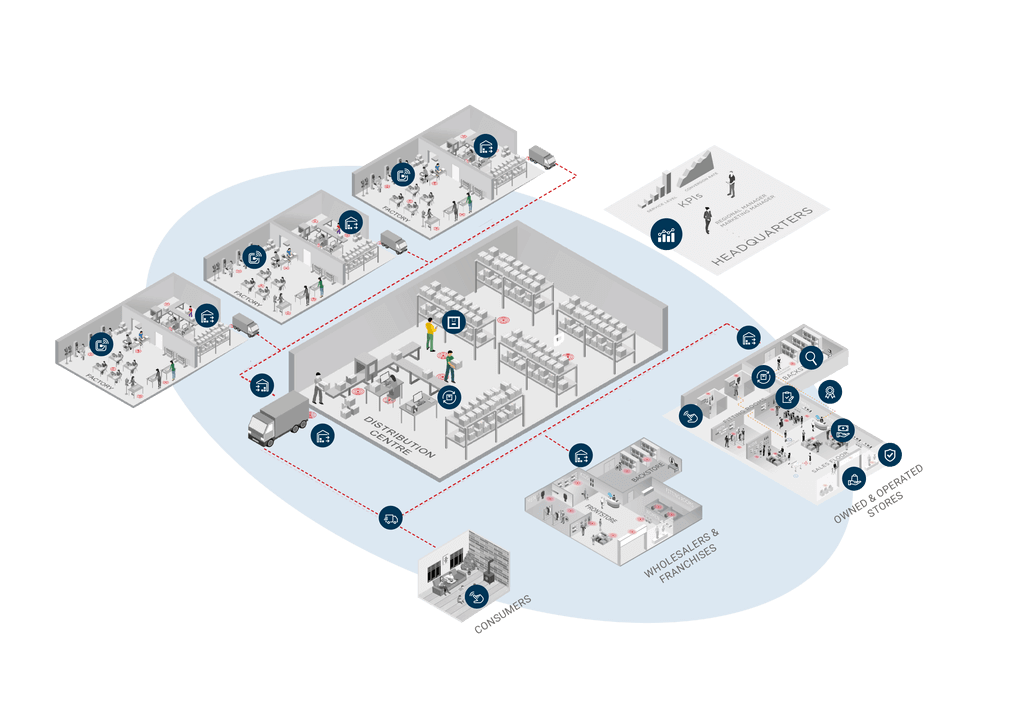

Fast forward to the present day, with advanced technology like RFID and the IoT, and the standard for retail supply chain management has changed. ‘Supply chain 4.0’ can effectively track and trace individual items from source to store, utilising RFID technology to track individual products and the Internet of Things to store and leverage this information on a digital platform or cloud.

The data and visibility provided by such digital supply chains are extremely valuable, allowing retailers to:

●Quantify the performance of the supply chain (visibility),

●Identify “the last known location of items” (accountability),

●Inspect the history of items and even raw materials (traceability).

Here are the 3 fundamentals of retail supply chain optimisation using item-level data:

Visibility

“To be able to see…”

Supply chain visibility is a growing priority for retailers. According to a report by Zebra Technologies, 72% of retailers are working on digitizing their supply chains in order to achieve real-time visibility. Knowing exactly what is in the pipeline allows retailers to control inventory more efficiently, improve operations between stores and DC’s as well as offer effective omnichannel services and delivery options.

However, the majority of supply chains don’t have anywhere near this level of visibility, as 62% of supply chains operate with a limited view over merchandise flow. This is because goods move along the supply chain in such large quantities, and most supply chains only account for cartons of items, rather than the items themselves.

For example, cartons of T-Shirts with quantities of around 50 are commonly sent out, but without RFID accounting for individual products, you can’t know if the quantities are correct. In other words, you are guessing what should be there as you do not have the visibility to know what is there. This may result in a store believing they have less or more products than they actually do. If however, they do identify the mistake, without visibility over the supply chain there is no way of knowing where the error occurred.

RFID technology can make every step along the supply chain visible while also providing a meaningful context, using digital ‘touchpoints’ to track items throughout their journey. RFID Tunnel installations can even automatically process these cartons, to identify shortages and surpluses all without opening the box. This way large inbound and outbound shipments can be processed quickly, accurately and down to the item-level.

Traceability

“To be able to verify the history…”

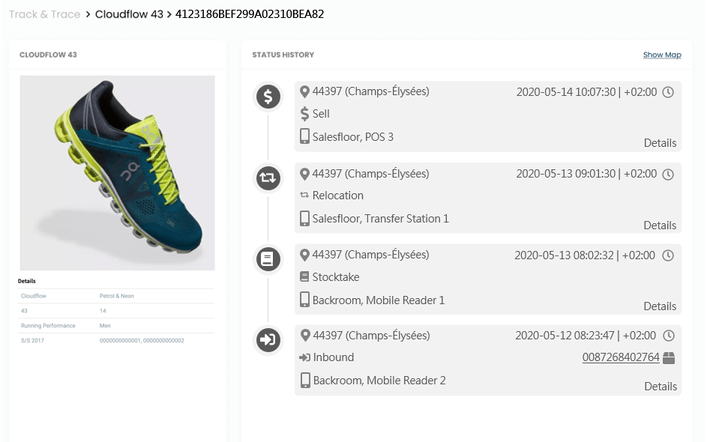

If supply chain visibility allows us to know where items are right now, traceability means being able to look back at where they have come from. As items are tracked through the supply chain with RFID, a record of all read events is stored on the cloud. Not only this, but the data from the product journey can be combined with similar data from materials used in each product. This information means retailers can not only see the last locations and events of items but they can also:

- Inspect their history (inception to sale)

- Change layers of abstraction (e.g., from item to carton)

- Go back to the source (materials sourced from cotton farms)

Having the ability to trace individual items back through the supply chain allows retailers to identify where shrinkage occurs and trace products back to the source in the case of a product recall. The traceability is also key as it involves keeping a permanent record of supply chain flow, not only does this mean valuable data, it also gives supply chain leaders the concrete evidence to hold suppliers accountable…

Accountability

“To be responsible…”

With digital track and trace technology in place, retailers will have access to the all-important last known location of items.

This means it is possible to identify where errors occur and hold supply chain and retail partners accountable. On the other hand, it can also serve as proof of service.

This information is also invaluable when it comes to brand protection. Not only can RFID technology easily identify counterfeit products but using the last known location of products allows retailers to identify how legitimate products end up on the grey-market. This is achieved by tracing them back to their last known location in the supply chain.

Knowledge of when and where an item was last seen/did not show up also dramatically speeds up clarification and accountability processes.

These 3 building blocks allow the extraction of KPIs and models to:

- Monitor shrinkage

- Identify grey imports

- Minimize counterfeits

- Automate re-ordering via dwell times and throughput

- Identify bottlenecks.

Looking to optimise your retail supply chain? The Detego platform is the end-to-end track and trace solution

Achieving complete supply chain transparency requires implementing an RFID system across your entire value chain, preserving detailed information about each RFID read event of each individual item (such as inbound verification, stocktake or sale). Thanks to that, knowing an item’s EPC (Electronic Product Code) number is enough to find out what, where and when happened to it. This capability is most useful when stores, distribution centres and factories are all integrated with one system – that system is Detego.

With efficient RFID processes from source-to-store, retailers not only gain new levels of accuracy and efficiency but achieve unprecedented transparency of the supply chain. Detego’s Global Track and Trace feature deliver the visibility, traceability and accountability to optimise retail supply chains for sustainable retail success.

Webinar: Item-level reporting from source-to store

Digitisation and data go hand-in-hand. As retail supply chains continue to go digital, a wealth of item-level data on the flow of merchandise through the supply chain is unlocked. In the future, the winners and losers of supply chain management will be determined by who leverages this information more effectively.

Join Detego’s Chief Data Scientist, Simon Walk, as he presents the cutting edge of supply chain analytics and how digitisation is taking the guesswork out of retail logistics.

This webinar covers:

• Item-level tracking of Items along the Supply Chain to deliver accountability, visibility & traceability

• Effective traceability which combats supply chain shrinkage and counterfeit products.

• Using heuristic & Machine Learning based Algorithms to detect supply chain irregularities.

• Using dwell-time data to optimise operational & Supply Chain processes

• Analysing throughput data across factories, DCs and stores

Webinar Recording: Best Practice RFID for Retail Supply Chains

Retail has evolved dramatically in recent years, driven by changing customer expectations, online disruption, and the ongoing digitisation of the industry. Whilst many stores are embracing technology to wow customers and deliver seamless experiences across multiple channels, behind the scenes supply chains are evolving too.

In this webinar we outline how Radio Frequency Identification (RFID) technology is strengthening supply chains and delivering the accuracy and transparency that modern retail demands. Covering the item-level journey from source to store, the presentation will explain how and why major retailers are choosing RFID to digitise and future-proof their supply chains.

This webinar covers:

- The business case and benefits which RFID technology can bring to the retail supply chain

- Key RFID processes and use cases in factories and distribution centres/warehouses

- Best-practice approach and strategy for implementing RFID across the supply chain

- Examples of successful customer implementations and learnings

- Critical insights to successfully manage new supply chain challenges during COVID-19 pandemic