Are retailers ready to improve the warehouse operations that sit at the heart of their supply and demand models?

Retail Warehouse Management: A Quick Guide to Success

Retail’s warehouse management systems are currently in a state of flux.

Supply chains are in crisis, consumer demands are unpredictably fluctuating, and labour shortages have reached historic heights – all disrupting the sector’s ability to fulfil even the basics of their supply and demand propositions.

Pair these challenges with the current e-commerce boom, and the result is a pivotal moment in time for the reinvention of retail logistics. In fact, investment in UK warehouses has already exceeded £6 billion this year, while the global warehouse automation market is expected to reach $30.99 billion by 2025.

Warehouses and distribution centres are undeniably the backbones of any retail operation, as departments that control the delivery of goods to consumers who — from their fingertips — expect accurate, timely, and efficient services regardless of what obstacles a retailer faces that week.

But to meet expectations, businesses must focus not just on sharpening their warehouse operations but also welcoming change and catalysing it into an opportunity for strategic innovation.

The Changing Models of Warehouses and Distribution Centers

Innovation within warehouse management is not just limited to improving tried and tested processes with technology. It is currently ripping up legacy systems as we know them and completely rethinking how the departments can be designed, fit for — post-pandemic — purpose.

Here we explore several new big-picture strategies that entirely remodel the way warehouses and distribution centres have traditionally functioned:

Micro-Warehousing

The tandem rise of e-commerce and consumer expectation for fast and efficient home delivery has inspired retailers to decentralise their once mammoth hubs and create physically segregated yet digitally connected operations through micro-warehousing.

Micro-warehouses and fulfilment centres allow retailers to house stock closer to their customer communities, enabling same-day delivery and click-and-collect services. They also help businesses optimise underutilised brick-and-mortar presences by repositioning them as dark stores — that exclusively cater to online purchases.

Distribution and Warehousing as a Service (DaaS, WaaS)

With companies facing new and unexpected obstacles every day, it’s no surprise the that B2B service market is booming. One of the latest propositions the retail sector is testing out is DaaS and WaaS.

Such services enable businesses to outsource these essential departments, radically shifting the strain of dealing with challenges like supply chain disruptions and labour shortages onto external partners who are better equipped to overcome such hurdles. Using WaaS and DaaS is a gamechanger for small and big businesses, assisting SMEs to manage quick growth without risking capital and helping large enterprises focus on other business activities without the distractions of logistical nightmares.

On-Demand Warehousing

With customer demand for goods straying away from typical timelines, businesses are increasingly unsure of how they will adapt to surging trends that follow no predetermined calendar. That is why on-demand warehouse services are becoming more popular.

On-demand warehouse platforms help retailers to find the perfect spaces for their immediate and short-term needs. This setup works with the fluidity of the global retail market, allowing companies to respond to rapid fluctuations, pilot stock with entirely new customer bases, and cater to unexpected peaks in demand – all while removing long-term and rigid contracts.

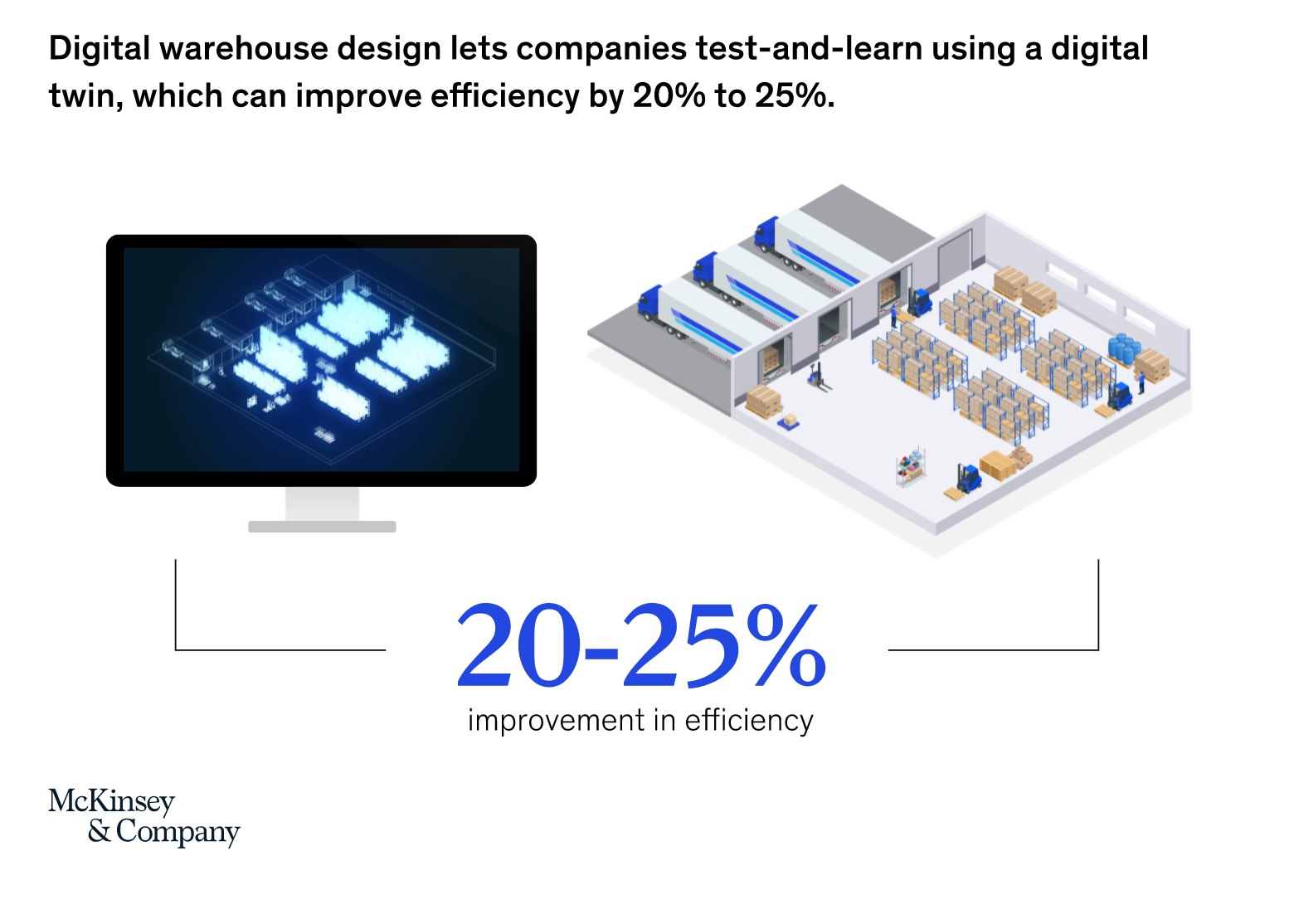

Digital Warehouse Twinning

If retail has learnt anything over the past 18 months, it’s that preparing for every unexpected eventuality is vital. That is why businesses are beginning to use technology to better their foresight.

Digital warehouse twinning is currently experiencing an uptick in use with retailers and is predicted to provide a 20%-25% uplift in efficiency. By building a digital twin of their warehouse, businesses can test new strategies and analyse the results of the operational changes they intend to make, all within a simulation. According to McKinsey & Company, this helps businesses make both big and small decisions — like floorplan redesigns and changes in workflow structures — without impacting the everyday functions of their warehouses.

The Future of Warehousing is Digital

Whether retailers intend to simply refine their existing warehouse processes or overhaul their models completely, it is no secret that digitisation will be embedded into the foundations of change.

Over the past 18 months, the adoption of technology has been essential for any business, helping them build agile, resilient, and responsive operations. And now, as retailers reflect upon their performance since the arrival of Covid-19, they’ve realised that quick decisions to implement innovation — once ideas born out of desperation — have grown in viability, becoming intrinsic to long-term strategies designed to help them succeed rather than just survive.

E-tailers like Amazon perfectly exemplify what it means to invest in cutting-edge innovation within warehouse operations whilst seeing a return on investment. For example, Amazon is known for their use of Autonomous Mobile Robots (AMR) to streamline logistics by picking and transporting stock without human supervision and integrating AI to predict inventory demand and help design floorplan navigations based on access needs. As a result, the industry leader in digital warehouse processes can deliver unapparelled levels of fulfilment across their global audiences.

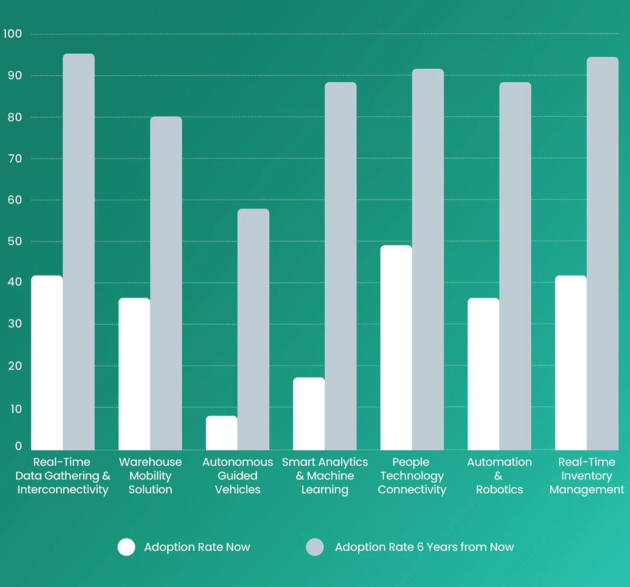

Taking a step back and looking at the retail sector as a whole, technology adoption within warehousing is set to soar over the next 6 years as these innovations evolve from being championed by evangelists into recognised processes with quantifiable results. Because according to the Harvard Business Review, there is plenty of room for improvement; 72% of companies believe their supply chain capabilities like warehousing and logistics to be digitally immature.

Technologies such as real-time data and inventory management are set to gain the most significant adoption rates in the next few years. And for good reason, the retail sector now knows that better stock visibility is necessary to make their activities intuitive to market volatility and shopper’s needs.

Why RFID is a One-Stop Solution for Operating a Warehouse with a Far-Reaching Impact

RFID technology provides real-time insights into inventory that currently helps retailers to solve many diverse challenges at once. Here we explore why integrating RFID into warehouses can allow businesses to achieve – what at first seem like wholly unconnected – business goals:

Creating Customer Loyalty

Building customer loyalty begins at the back-end of retail operations and not front-facing customer touchpoints. In fact, retail’s ramp-up of omnichannel – which has been firmly cemented as the go-to strategy for future success – has irreparably impacted how warehouses will need to function moving forward.

Delivering Fast Fulfilment through Product Transparency: When over 98% of shoppers claim delivery impacts their brand loyalty, shipping inaccuracies and delays are becoming a critical issue for retailers as demand for home delivery rises alongside e-commerce’s market takeover.

RFID’s ability to help businesses monitor inventory at item-level and in real-time means that product availability is becoming more accurate and automated as sales and returns are processed. As a result, companies can generate customer trust through the errorless communication of stock levels as they click-and-collect from stores and organise next-day delivery online.

Making Returns Easier with Shipping Accuracy: The rise of free returns policies has led to a mini-epidemic of high logistical costs and growing carbon emissions. In addition – according to the SOTI’S State of Mobility in Retail Report 2021 – over half of customers are unhappy with returns processes and want them made easier.

RFID reduces the risk of shipping mistakes by digitally automating the receipt of inbound goods to verify inventory and track individual stock pieces at every step of complex returns processes.

Reducing Costs and Optimising Efficiency

A rare new era of stagflation has arrived in the US and UK markets. Characterised by the inflation of prices, high unemployment – fuelled by “the great resignation” – and stagnant economic growth, industry experts, are wary of its long-term impact on the retail sector. As a result, retailers are becoming more cautious and considerate with every decision they make, hoping to reduce operational costs to keep prices low and demand high.

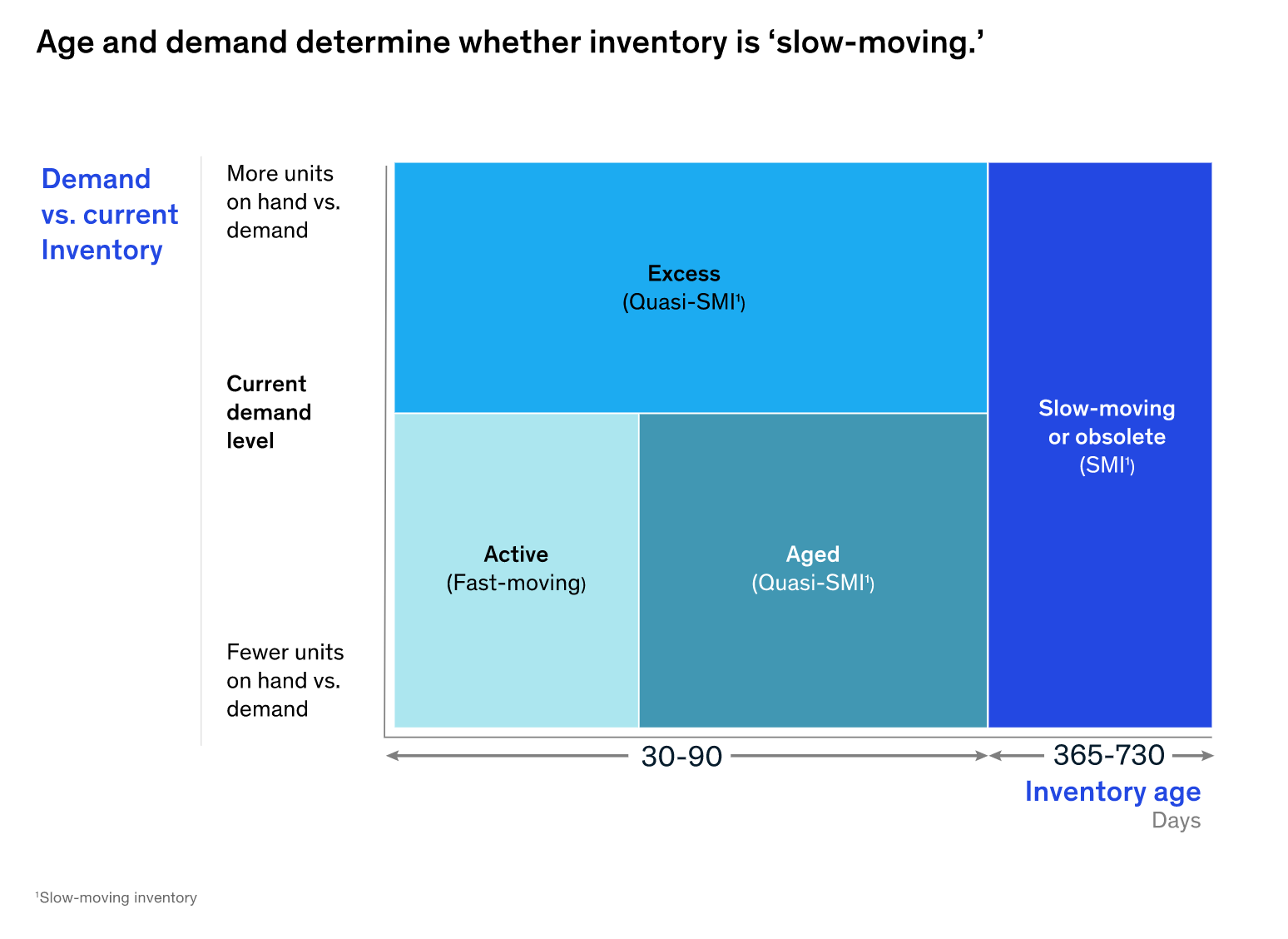

Managing Excess Stock through Inventory Protection: Slow-moving inventory has been a central problem for retail businesses, with the pandemic causing entire product categories such as evening-wear, holidays, and eating-out to become obsolete overnight. As a result, stagnating stock is a loss-leading problem that businesses are now beginning to tackle beyond outdated solutions such as seasonal sales, landfills and destruction.

RFID can help identify this stagnant inventory and trace its age and demand levels to inform how best to deal with stock in more sustainable ways. For example, the technology’s ability to trace individual goods back to manufacturers can additionally help to prove provenance as they enter resale markets.

Planning for the Future

Data is one of the most valuable assets a company can generate. It allows businesses to understand their customers on a granular level and trace what’s happening in their own ecosystems back to micro and macro market fluctuations. To plan more readily for the still unpredictable future, retailers are increasingly considering how to collect, connect and make sense of data to provide them with the best foresight.

Insights and Reporting through Label Printing: If businesses want to gain reliable and real-time insight into their logistics, they will need to imbed digital touchpoints into many of their existing processes. Warehouses present the perfect opportunity to create these touchpoints and track the inventory’s onward journey.

Quick and easy printing of RFID labels within warehouses can help enterprises with limited budgets to focus their intel-gathering on the journeys of specific stock. This can also enable smart shelving – a method of inventory visibility that allows retailers to trace customer engagement with stock as they pick it up and try it on. Insights generated this way help companies with everything from inventory planning to design development and visual merchandising.

Upskilling Workforces with easy RFID integration: The labour shortages that still plague the retail sector means that companies are becoming increasingly committed to investing in upskilling their workforce and providing them better tools to carry out everyday tasks.

Today, many RFID solutions are designed to work effortlessly with warehousing software, meaning the technology seamlessly fits into existing workflows without disruption. As a result, it helps make picking and packing less time consuming and laborious and increases employee’s ability to adapt to digital advancements with confidence and satisfaction.

Everything and Anything is Possible with Cloud Technology

Warehouses are the heart of any retail operation. As such, refining the processes within the walls of this department presents the opportunity to make widespread improvements across an entire business. Yet, so many of these advancements will be made possible by cloud technology.

Cloud technology allows different departments to automate inventory updates and access information in real-time, connecting workflows and injecting continuity into communication. Implementing cloud-based solutions into warehousing will provide retailers with the freedom of choice to radically change their models or merely update manual processes with digital.

Detego is a cutting-edge platform in the RFID space that delivers impact within their easily implemented cloud solutions. Book a consultation with Detego today to find out how they can help your business improve its warehouse and distribution centre practices and take the first steps towards implementing strategic innovation.

Cloud-hosted RFID software

Stock accuracy, on-floor availability, and omnichannel applications in stores.

Detego Store is a cloud-hosted RFID solution which digitises stock management processes, making them more efficient and more accurate. Implemented within hours, our multi-user app can provide intelligent stock takes and a smart in-store replenishment process. Later, you can scale the solution to offer omnichannel services and effectively manage your entire store operations with real-time, item-level inventory visibility and analytics.