Supply chain disruption can cause severe issues for retailers, but it’s possible to turn disruption to your advantage with retail inventory management software

Supply Chain Disruption: Turning It Into an Advantage with Retail Inventory Management

The past two years have been undeniably difficult for retailers. From reduced footfall in physical stores to grappling with staff shortages, there have been few advantages, and many long-term effects, to the recent disruption. The same is true for supply chain issues that have beleaguered retailers over recent years. Businesses have had to adapt to problems including shipping delays, higher delivery costs, and fluctuating consumer demands, and though we’re seeing the first signs of economic recovery, these issues won’t disappear overnight. Some analysts have predicted that it could take until mid-2024 for supply chains to return to relative normal.

So far, retailers have been forced to react to supply chain disruption as it happens, flexibly accommodating their business operations to the issues. However, there are ways for retailers to turn supply chain issues to their advantage, and the solution involves retail inventory management software.

Most businesses will already have some form of retail inventory management process; it’s a crucial part of omnichannel retailing, for example. But technology like RFID combined with powerful inventory software can offer a way for retailers to not only adapt to supply chain disruption but conquer it.

The Current Supply Chain Issues

The fallout from the Covid-19 pandemic is still being felt in global supply chains. While retailers have weathered the worst of the storm with regard to inventory delays, there are still challenges in the global supply chain that will inevitably take time to remedy. In fact, 94% of Fortune 1000 companies are still experiencing supply chain disruptions as a result of the pandemic.

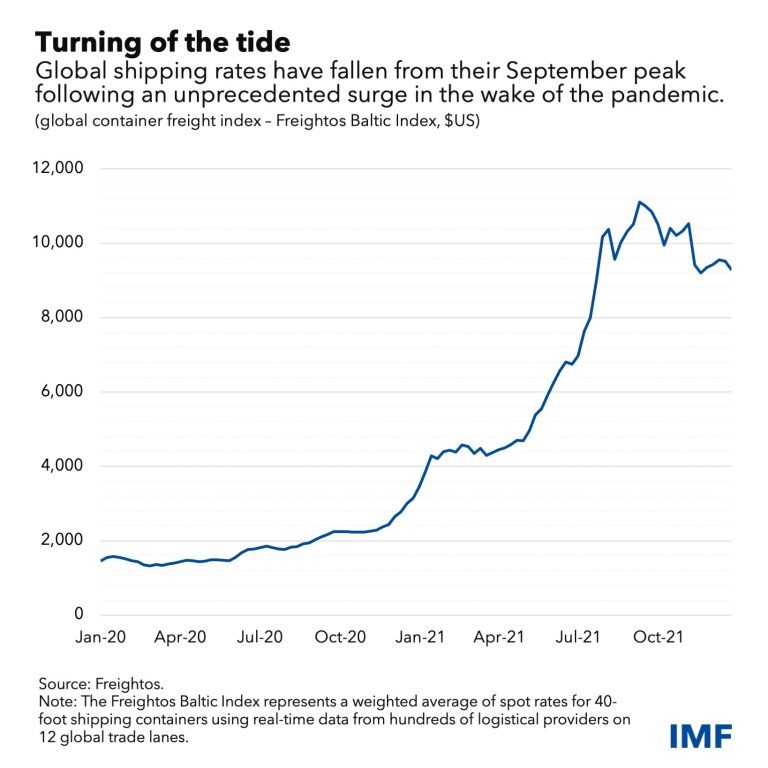

One of these major challenges is the cost of shipping. Global shipping costs spiralled in 2021, reaching a peak in the latter half of the year. In October, the average cost of shipping a standard 40ft container reached $10,000. Costs have since declined by 16%, but are still higher than in normal years – in some cases by more than four times the average. In 2019, the cost of shipping a container from Shanghai to New York was $2,500, but this has since risen to $15,000.

As well as increased costs to ship inventory from manufacturer to store, retailers also have to adapt to delays in shipping. The global supply chain is still adapting to Covid-19 setbacks, resulting in persistent delivery delays. At present, there are 20 million containers waiting at ports all over the world, and this backlog will take more than a few months to resolve. While the scale of the issue doesn’t compare to early 2021 – when supply chain delays and shortages were up 638% – many businesses will still be experiencing shortages or delays well into 2022.

Finally, there has been a shift towards more environmentally-friendly practices in a wide variety of industries. Companies are also looking at ways to make their supply chains and logistics more sustainable. This includes switching to more sustainable shipping options like biofuel instead of diesel, eco-driving, or moving operations closer to customers. However, a move towards sustainable operations is challenging and requires coordinating entire supply chain operations and more complex retail inventory management.

Outperforming During Disruptions

Despite ongoing supply chain troubles, some retailers have done more than just endure the issues – they have thrived on the disruption. Brands like Walmart, M&S, and Pets at Home have all posted strong growth over 2021, despite grappling with intense supply chain disruption. The one thing these brands have in common? Omnichannel retail.

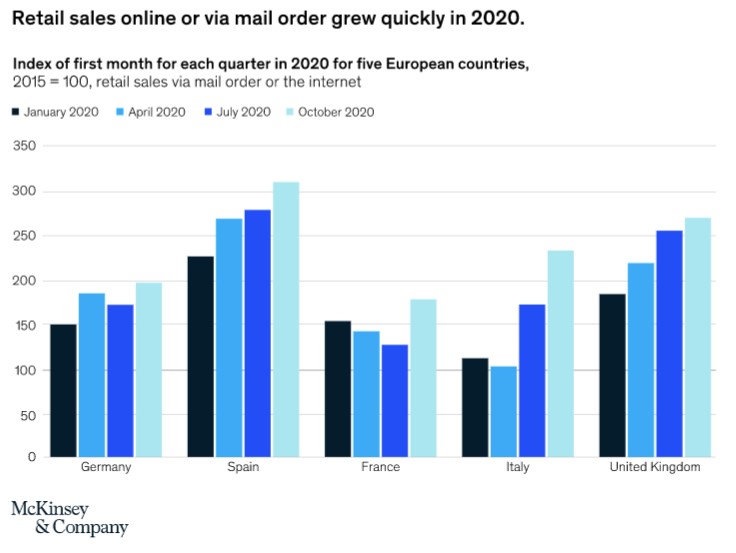

Over the last two years, consumers have switched from in-store shopping to online shopping. There was a pronounced switch to online retailing in 2020, which then persisted throughout 2021. In the UK, online sales made up 30% of overall retail spending in 2021. While still less than a third of overall spending, this is a jump from the 11% of sales that were conducted online in 2019.

However, for many retailers, it wasn’t simply a question of turning attention to online sales. Instead, an omnichannel solution that combined in-store shopping and online options proved the most effective option. Nike, for example, continued with plans to open a flagship store in Paris during the pandemic. Instead of floundering as footfall in brick-and-mortar stores fell, they found that the physical store also helped drive online sales. Retailers who open a new physical location can see a 37% increase in traffic to their website in the following quarter.

For some companies, it was a question of evaluating their supply chains and seeing where they could improve. Sports brand SylvanSport ran into issues when their overseas tire manufacturer couldn’t deliver on time, so they had to look at alternatives. This included seeking domestic manufacturers to create the product for them while still retaining their overseas manufacturer for future orders. This flexibility within their supply chain allowed them to easily adapt to any issues as well as future-proof their operations in case of further disruption.

How to Adapt to Disruption

It’s clear that supply chain challenges aren’t going away anytime soon. Consequently, retailers must plan for periods of disruption and find a way to come out of them performing stronger. For a start, we know that retailers who have outperformed during the last two years have focused on a few things: omnichannel solutions, consumer trends, and real-time data.

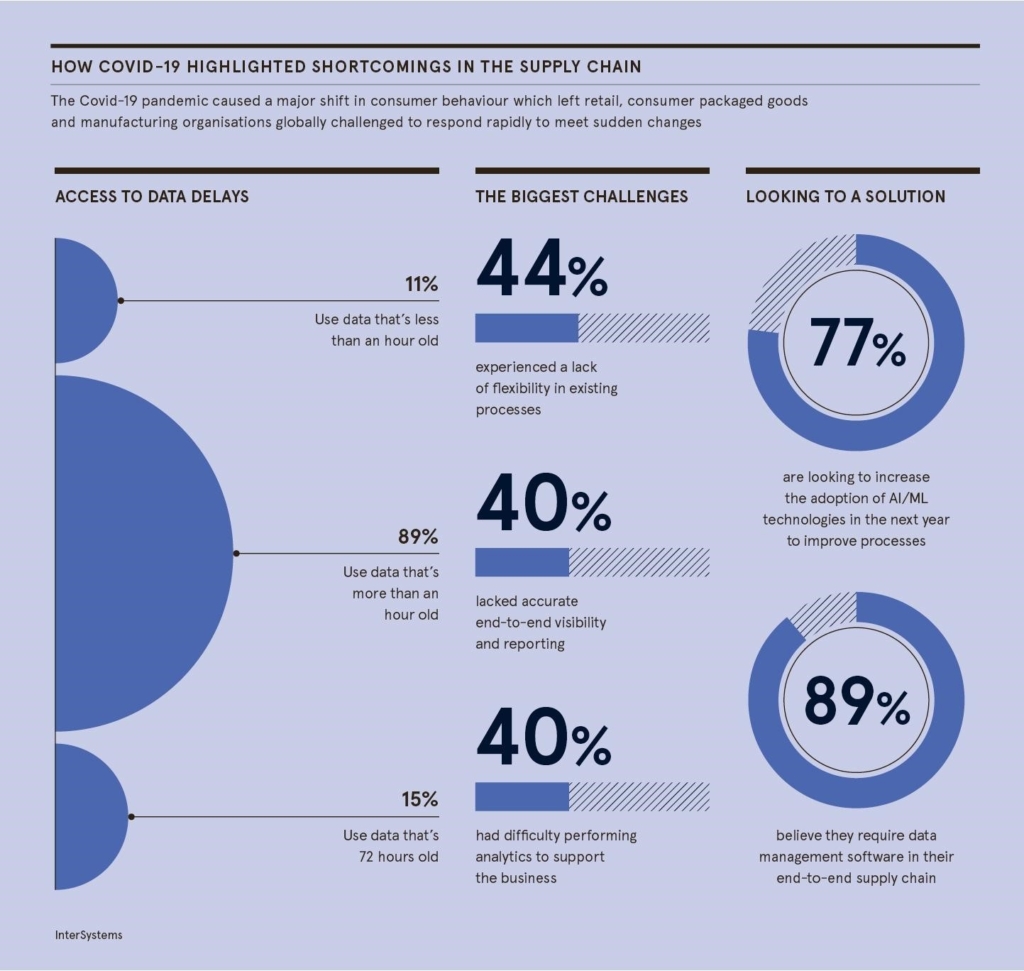

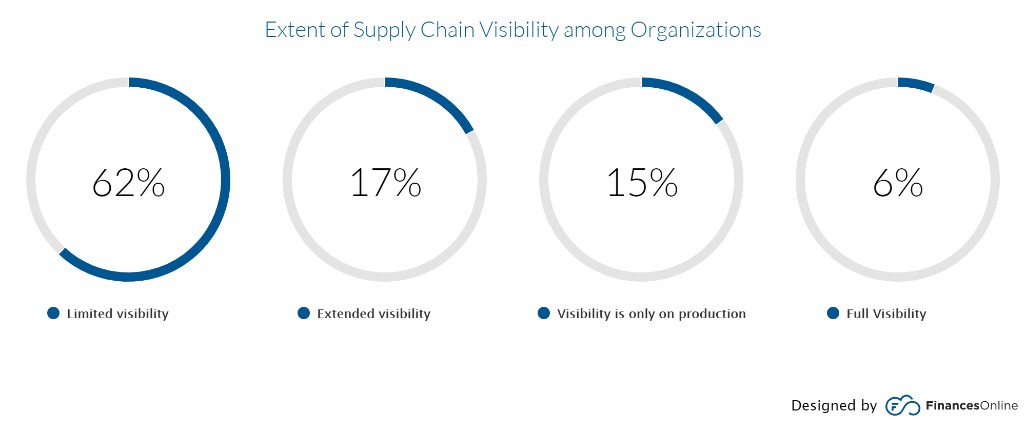

Data is a powerful tool when it comes to adapting to supply chain disruption, but many retailers aren’t taking advantage. In fact, 54% of company executives have said they don’t have clear visibility of their supply chain past Tier 1, and an additional 40% of companies don’t have accurate end-to-end visibility and reporting. This means that any disruption in the early stages of their operations will go unseen, and the consequences felt only when it’s too late.

However, companies are learning that technology like retail inventory management software is a powerful way to improve their operations – 89% of retail organisations said they will need to implement data management software in their supply chain.

Companies that do turn to AI-powered data solutions inevitably become more resilient. Having a clear understanding of supply chains, and their weaknesses in them can make companies more able to adapt to difficulty when it arises. When Japan was hit by a magnitude-9 earthquake in 2011, production at Toyota’s factories ceased for two months. After this, they focused on building an accurate database of their suppliers and parts to track their operations and products through the supply chain. In 2016 and 2019, when more earthquakes hit Japan, Toyota had reduced their production stoppages to just two weeks.

We also know that omnichannel services are the way forward for modern retailers. Consumers are asking for alternative ways of purchasing products, and omnichannel retailing also paves the way for future technology like AI-powered brick-and-mortar stores and virtual shoppers.

Since the beginning of the pandemic, one-third of American shoppers have taken advantage of omnichannel services including deliver-to-store, and two-thirds of those shoppers plan to continue taking advantage of omnichannel retailing in the future. As the previous example from Nike demonstrates, it’s not about turning 100% to online services, but about offering multiple opportunities for consumers to purchase products.

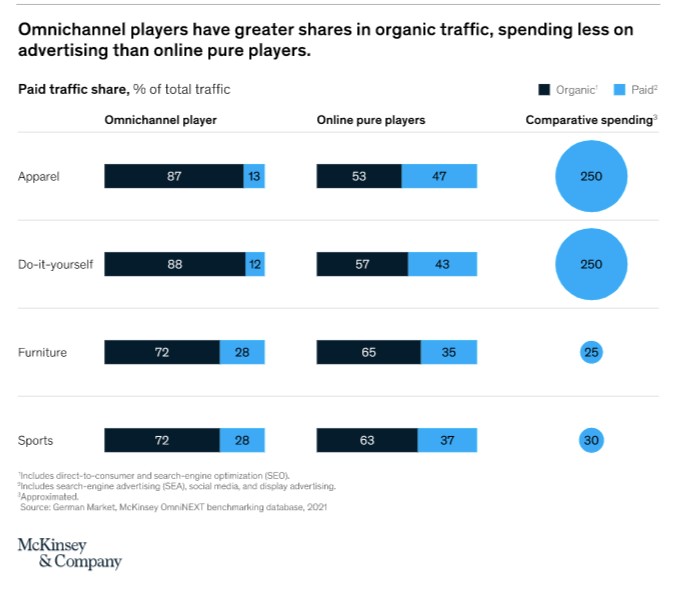

According to a study from McKinsey, brick-and-mortar retailers – though at a disadvantage over the last two years due to a decrease in footfall – still have to spend comparatively less on advertising in order to reach the same amount of customers as online retailers. So, it’s about developing an approach to omnichannel that blends online and physical retailing, allowing customers to purchase exactly when and how they want.

The final way retailers can increase the resilience of their operations and their supply chains is by paying close attention to changes in consumer behaviour. Arguably the biggest consumer trend for 2022 is a shift towards sustainability. In 2021, one in three consumers stopped buying certain brands because of sustainability or ethical concerns, and 46% of consumers wanted additional information over the origin of their products. To retain consumers in the coming years, it’s crucial that brands consider the environmental impact of their supply chains and make the necessary changes before customers choose alternative products.

The Benefits of Retail Inventory Management Software

We’ve identified three ways to turn supply chain disruption to your advantage: developing an omnichannel strategy, harnessing the power of digital insights, and staying aware of consumer trends. For all of these strategies, it’s crucial that companies dedicate some time to reviewing their retail inventory management system. Without a successful system in place to track and count inventory, you won’t be able to implement omnichannel services or make changes to your supply chain in reaction to consumer trends.

In order to accurately track inventory and respond to supply chain disruption, companies should consider investing in retail inventory management software. An all-in-one retail inventory management software, with the help of RFID tags in your supply chain, can provide businesses with real-time insights and inventory flexibility to increase supply chain resilience.

Real-Time Insights

An all-in-one retail inventory management software offers retailers real-time insights that can transform operations. While digitising your entire supply chain might seem like a mammoth task, RFID supply chain technology is becoming more accessible and easy to implement.

In particular, the ability to monitor supply chains at all times, and receive real-time data from supply chains, makes it easier to make operations decisions fast. When the container ship, the Ever Given blocked the Suez Canal last year, 15% of the world’s freight was impacted. Implementing solutions quickly became of the utmost importance – only companies who had immediate insights into the effect of the crisis on their operations could make decisions to avert supply chain disasters.

Retailers that had already implemented a retail inventory management solution could immediately make decisions to shock-proof their operations from the disaster and recover more quickly.

Supply Chain Visibility

In order to adapt to disruption, it’s important that businesses have a clear, end-to-end view of their operations. However, many businesses currently don’t have the level of supply chain visibility necessary to quickly adapt to disruption. Retail inventory management software, when paired with RFID tags in the supply chain, can give businesses the visibility they require to outperform.

Only with a clear view of the supply chain from manufacturer to store can businesses accurately see where their stock is and react to shipping errors or delays. This is even more crucial as businesses turn to omnichannel experiences to boost sales, where it’s crucial to see where stock is and ensure that other services like ship-to-store or store pick-up can happen successfully.

Not only does retail inventory management software offer businesses end-to-end insights into their operations, but it can also help with sustainability efforts by enabling operations to be fully transparent to consumers.

More Accurate Inventory Counts

Implementing RFID in your supply chain can also make it easier to get accurate inventory counts. When there’s a disruption to inventory deliveries, knowing exactly what stock you have can make a big difference to your sales and allow store changes to be made swiftly. When used alongside a retail inventory management platform, RFID tags can help achieve 99% stock accuracy.

RFID technology enables retailers to quickly see which stock may incur delays and prepare for potential out of stock notices. For example, Reiss increased their sales by 4% by increasing their stock accuracy as they had an accurate view of exactly what stock was available and where. This makes it easier to implement omnichannel strategies like buy-online-pick-up-in-store (BOPIS). With accurate stock counts, it’s also easier for retailers to quickly adapt to consumer trends, focusing their attention on only the stock that is selling well.

Retail inventory management solution

Stock accuracy, on-floor availability, and omnichannel applications in stores.

Book a demo with Detego to find out how our cloud-hosted retail inventory management solution could help you outperform competitors and adapt to supply chain disruption. Our multi-user app can provide intelligent stock takes and a smart in-store replenishment process and later, you can scale the solution to offer omnichannel services and effectively manage your entire store operations with real-time, item-level inventory visibility and analytics.